Production

-

Unifying Factory Solutions for Smarter Production

Explore how Autodesk’s integrated factory production solutions help manufacturers optimize factory layouts, streamline production processes, and improve operational efficiency for smarter, faster factory production. Autodesk is entering a new era of unified production—one where smart collaboration and digital factory solutions converge to transform how products are designed, engineered, and manufactured across industries. By integrating FlexSim with AutoCAD, Inventor Factory Design Utilities, Vault – and introducing…

Production

-

Demand-Driven Success: Lean Production Meets Just-In-Time (JIT)

Lean production and just-in-time (JIT) manufacturing work together to eliminate waste, reduce inventory, and create agile, demand-driven production systems that maximize efficiency, quality, and customer value. Understanding lean production just-in-time (JIT) Manufacturing companies around the world have discovered that lean production and just-in-time (JIT) methodologies represent the most effective approach to eliminating waste while maximizing…

Production

-

Comprehensive Guide to Manufacturing Resource Planning (MRP II)

Manufacturing resource planning (MRP II) helps companies optimize their manufacturing processes, covering everything from materials to labor costs. This guide explains MRP II, its benefits, how it differs from MRP I and how Autodesk Fusion Operations can enhance MRP II. Understanding manufacturing resource planning (MRP II) Manufacturing resource planning (MRP II) is an integrated information…

Production

-

The Digital Factory: Analytics and Cloud Platforms for Smarter Manufacturing Decisions

Examine how advanced analytics and cloud platforms turn manufacturing into digital factories with actionable insights for agility and flexibility. Learn how Autodesk Factory Design Utilities unifies design, simulation, and collaboration to optimize operations and stay resilient in a competitive and unpredictable market. Manufacturing has reached a stage where traditional approaches are no longer viable. Instead,…

Production

-

Enhanced Efficiency with Just-In-Time (JIT) Tools in Manufacturing

JIT tools significantly enhance manufacturing efficiency by automating and optimizing tasks. Autodesk’s Inventor, Vault, and Factory Design Utilities aid in improving production processes and workflows. Are increasing manufacturing inefficiencies giving you a headache? Just-in-time (JIT) tools can streamline and automate tasks, greatly enhancing manufacturing efficiency. Let’s explore the uses and benefits of JIT tools, specifically…

Production

-

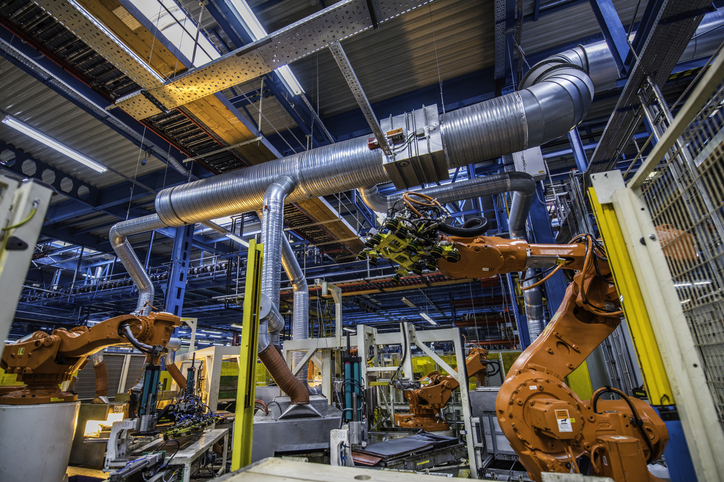

Trends in Industrial Automation: Transforming Manufacturing in 2025 and Beyond

Industrial automation, projected to reach $378.57 billion by 2030, is being transformed by IIoT, Industry 4.0, AI, edge computing, collaborative robots, and 5G. These technologies enhance real-time monitoring, predictive maintenance, and operational efficiency in manufacturing. Industrial automation – key takeaways The manufacturing landscape is changing as emerging technologies reshape how companies approach production, efficiency, and…

Production

-

How the Digital Factory is Disrupting Traditional Manufacturing

The digital factory is changing manufacturing by making processes more agile, scalable, and resilient through real-time data, automation, and integrated design tools like AutoCAD, Inventor, and Factory Design Utilities. The digital factory is creating a significant shift in manufacturing. Advanced technologies and innovative software platforms have transformed traditional, rigid processes into agile, data-driven, and resilient…

Design & Engineering

-

Digital Factory Virtual Summit 2025

Join an exclusive gathering of industry leaders and executive decision-makers at the EMEA Digital Factory Virtual Summit—your gateway to the future of manufacturing.DATE: 8 October 2025TIME: 11:30 AM CET | 10:30 AM BSTExplore how cutting-edge digital technologies are transforming factories—boosting throughput, enhancing flexibility, accelerating time to market, and advancing sustainability. This is more than a summit; it’s…

Autodesk Factory Design Utilities

-

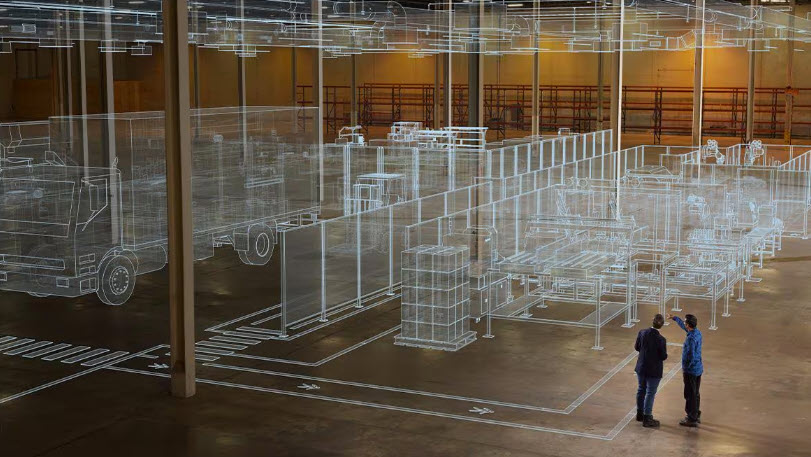

Factory Design Made Easy with Autodesk Solutions

Factory design is made easy with Autodesk’s solutions that enhance the process through integrated tools, improving collaboration, efficiency, and overall manufacturing output. Imagine a world where the creation or retrofitting of your next factory translates into enhanced manufacturing output. Construction progresses alongside machine installation and the evolving production line. This is a world void of…

Production

-

Manufacturing Optimization: Improving Processes & Efficiency

Manufacturing process optimization enhances efficiency, reduces costs, and improves product quality through methodologies like lean manufacturing, Six Sigma, and advanced technologies such as automation and Industry 4.0. Manufacturing process optimization for efficiency Manufacturing process optimization is not just a strategic advantage; it’s a necessity driving manufacturing optimization that balances cost, quality, and speed. Optimizing manufacturing…

Production

-

Digital Factory Planning: Achieve Success with Autodesk

Establishing a new factory is a complex investment requiring meticulous planning, collaboration, and execution. Learn how Autodesk’s digital factory solutions can help. Standing up a new factory is most likely the largest single investment a company can make. This massive undertaking involves extensive planning, collaboration, and execution. Despite rigorous planning processes, companies often face cost…

Production

-

Which Digital Manufacturing Trends Are Changing the Modern Factory?

Explore four major trends in digital manufacturing—automation, digital twins, sustainability, and workforce digitization—and see how Autodesk solutions help factories implement and scale these innovations. Since the first industrial revolution, factories have continued to evolve at a rapid pace. In 2025, factories are increasingly defined by their digital tools and ability to perform data-driven decisions. Currently,…

Production