Production

-

Inventory Optimization: How Autodesk FlexSim Turns Complexity into Clarity

Inventory optimization with Autodesk FlexSim helps manufacturers and warehouses cut costs, prevent bottlenecks, and boost efficiency using simulation and optimization tools. Inventory optimization has become a mission-critical priority for manufacturers, warehouses, and supply chain leaders. Rising volatility, demand swings, and pressure to cut working capital are forcing organizations to make faster, smarter decisions about inventory levels. But too…

Production

-

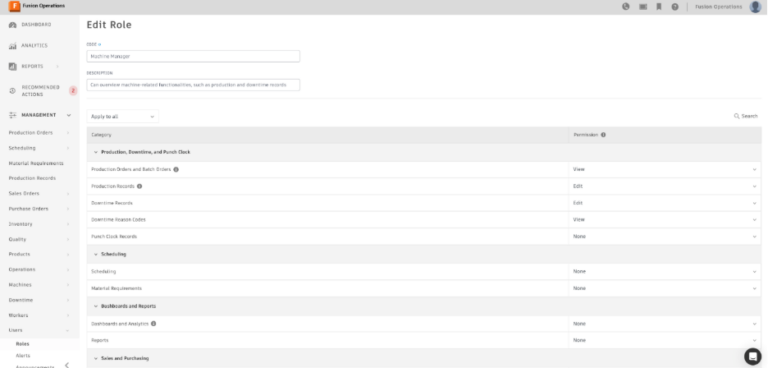

Take Control of Your Manufacturing Processes with Customizable User Roles in Fusion Operations

Control who sees and edits production data with customizable user roles in Fusion Operations. Improve security, accuracy, and productivity across manufacturing teams. If you’re already using Fusion Operations to track and schedule your production processes, you know the value it adds to your daily operations. That means a lot of data, often more than a single user needs to see…

Production

-

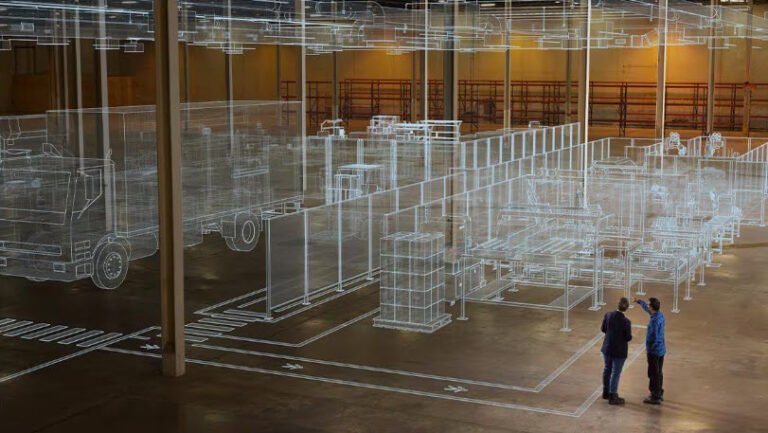

Connecting FDU and FlexSim for End‑to‑End Factory Simulation

Learn how connecting Autodesk Factory Design Utilities (FDU) with FlexSim enables true end‑to‑end factory simulation, improving throughput, reducing risk, and optimizing layout and operations. Production bottlenecks, resource constraints, and unpredictable shifts in demand can derail even the best factory planning. Factory simulation helps address these challenges by revealing how a system behaves under real‑world scenarios…

Production

-

Optimizing Warehouse Throughput with Material Handling Strategies

Discover how optimized material handling strategies—such as zoned presorting, batching, and workflow redesign—can significantly increase warehouse throughput with Autodesk FlexSim. Introduction: Why material handling drives warehouse performance Material handling is one of the most influential factors affecting operational success in today’s distribution centers. In facilities that span hundreds of thousands of square feet, every second…

Production

-

Digital Twin and Discrete-Event Simulation: Driving Efficiency Before the First Machine Starts

Explore how manufacturers use digital twins and discrete-event simulation to boost efficiency before production starts. It covers how simulation models system operation over time and how Autodesk FlexSim supports early decisions, factory planning, and ongoing process improvement. Today, manufacturing teams face important decisions well before installing equipment or starting a production line. To address this,…

Production

-

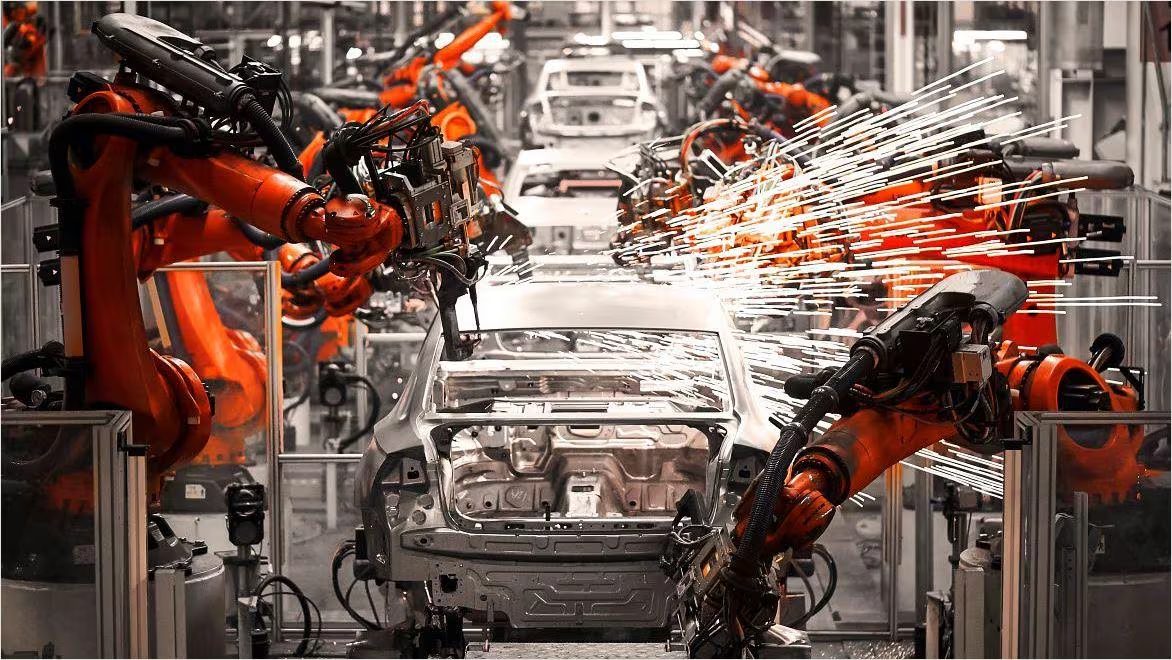

Building Flexible Manufacturing Systems for Unpredictable Markets

This article examines the importance of Flexible Manufacturing Systems (FMS) in navigating volatile markets. It explains how modular and reconfigurable setups help manufacturers pivot production and manage supply disruptions. Learn how Autodesk solutions, like Inventor and Fusion, facilitate agility through automated asset modeling, process simulation, and cloud collaboration. In modern manufacturing, volatility is the norm.…

Production

-

Accelerate Time-to-Market and Reduce Risk: The Six Phases of NPI Explained

Learn how structured NPI processes cut time-to-market by up to 50%, improve quality, and enable cross-functional collaboration for manufacturing leaders. Why NPI matters New Product Introduction (NPI) is the structured process that transforms ideas into market-ready products. Companies that implement formal NPI frameworks achieve 30–50% faster time-to-market and 40% fewer post-launch quality issues compared to…

Design & Engineering

-

Unlocking Manufacturing Agility: How the Autodesk Product Design & Manufacturing Collection Drives Results

Discover how the Autodesk Product Design and Manufacturing Collection helps manufacturers overcome today’s challenges with integrated design-to-manufacturing workflows. Manufacturing today: Complex and demanding Manufacturing leaders face unprecedented complexity. Global supply chain disruptions, labor shortages, and sustainability mandates are reshaping the industry. At the same time, customers expect faster delivery of customized products without sacrificing quality.…

Design & Engineering

-

JIT Management in a Digital Manufacturing World

Explore how AI, IoT, and automation strengthen modern JIT management while addressing challenges related to supplier reliability and uncertain demand. As global supply chains become more interconnected, they become more fragile. In this context, successful just-in-time (JIT) strategies require more than traditional lean practices. They now need digital technologies capable of sensing, predicting, and adapting…

Production

-

Smart Factories as Business Imperatives

This article explores how smart factories turn real-time data into business intelligence that drives efficiency and agility. It examines the technologies powering this transformation and how Autodesk solutions like Autodesk FlexSim and Fusion Operations enable manufacturers to optimize performance, sustainability, and profitability through connected digital systems. Factory operators are converting traditional factories into “smart” facilities…

Autodesk FlexSim

-

Discrete Event Simulation (DES): The Engine Behind Data-Driven Manufacturing Decisions [Update 2025]

Discrete event simulation (DES) enables manufacturers to analyze, model, and optimize complex production systems without disrupting real-world operations. As the manufacturing ecosystem grows more dynamic—with variables like supply chain volatility, custom product demands, and automation—DES provides a virtual sandbox for experimentation, forecasting, and cost optimization. How discrete event simulation (DES) & modeling helps manufacturing make…

Autodesk FlexSim

-

Just-in-time (JIT) Manufacturing Benefits [Update 2025]

Just-In-Time (JIT) manufacturing enhances efficiency, reduces waste, lowers inventory costs, improves quality control, and boosts customer satisfaction by aligning production with lean principles. Just-in-time (JIT) manufacturing offers a powerful approach to streamline operations, reduce waste, and align production directly with customer demand. Rooted in lean manufacturing principles, JIT has revolutionized how manufacturers increase efficiency and…

Production