Autodesk Inventor

-

Best Practices for Scaling Design Automation

Design automation tools boost innovation, streamline manufacturing, and reduce repetitive tasks, helping meet customer demands.

Autodesk Inventor

-

Teollisuuskopla Oy Gains New Business Advantages with Autodesk Cloud PLM

Teollisuuskopla Oy streamlines engineering projects with Autodesk cloud PLM, enhancing collaboration, data management, and procurement efficiency across Finland.

Autodesk Fusion Manage

-

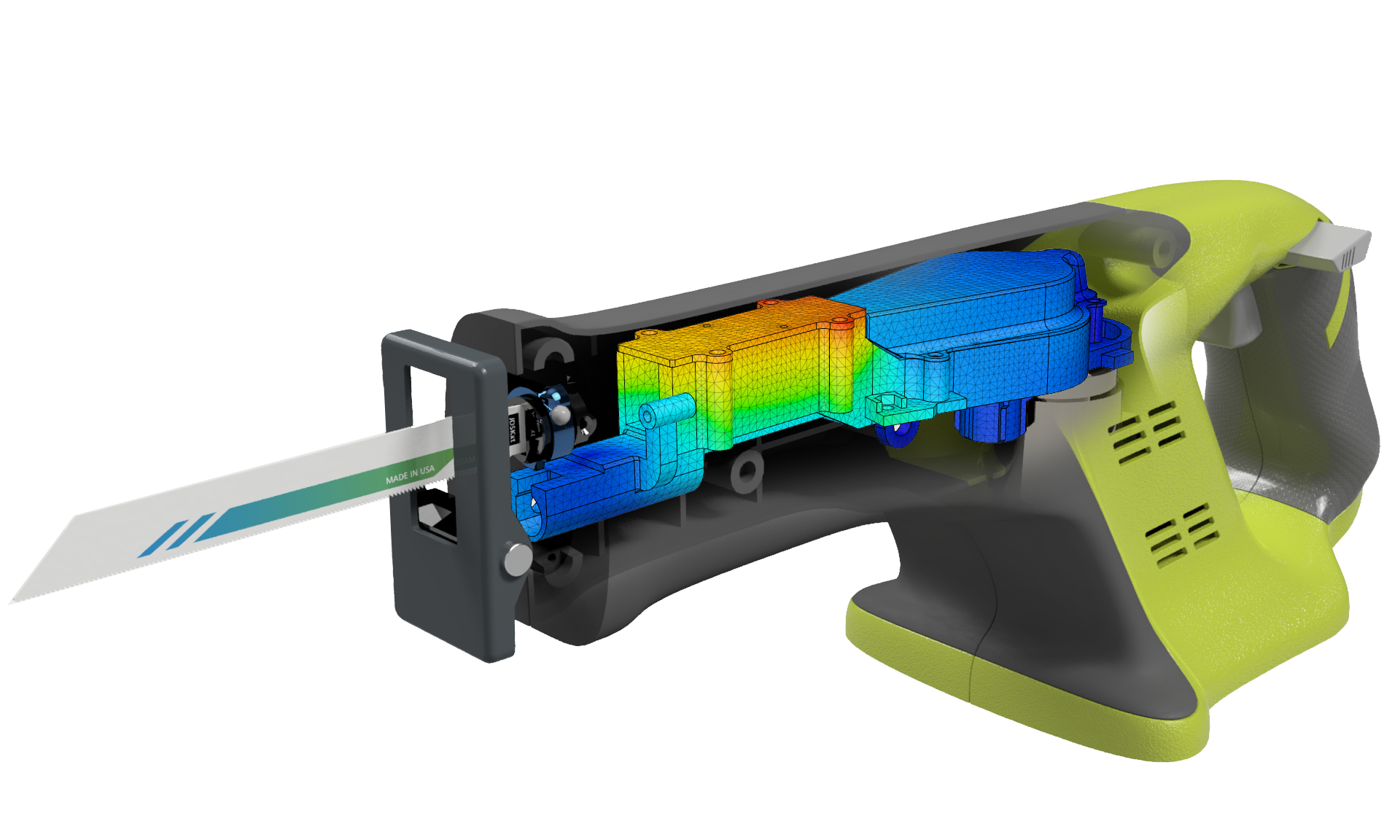

Modal Analysis: An In-Depth Look

Modal analysis is an important tool in design and manufacturing processes, ensuring product reliability, safety, and cost-effectiveness.

Autodesk Inventor

-

Large Assemblies: 10 Tips for Managing Them in Autodesk Inventor

Working with large assemblies in Inventor can get complex. Let’s dive into 10 tips that will help you work more efficiently.

Autodesk Inventor

-

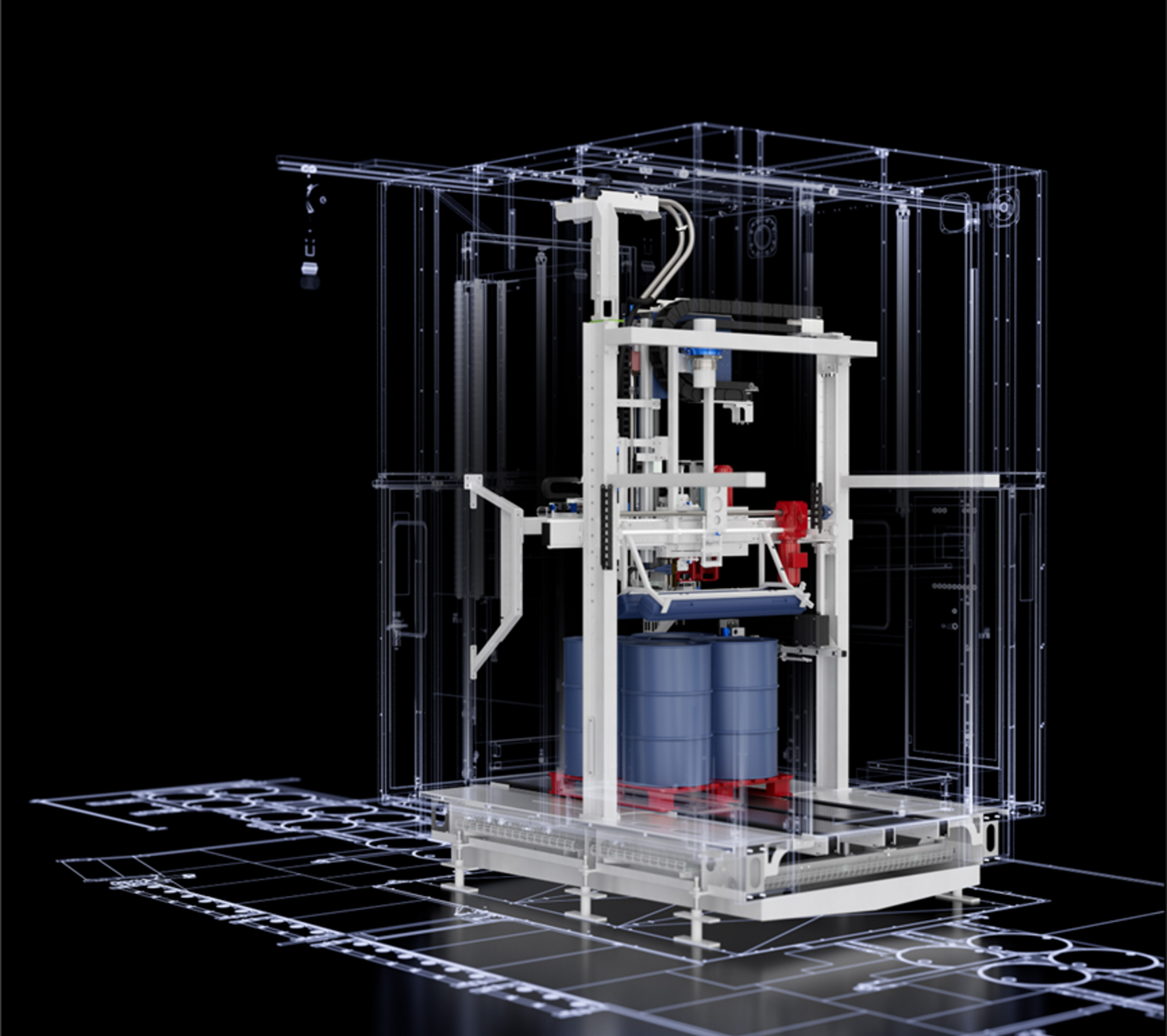

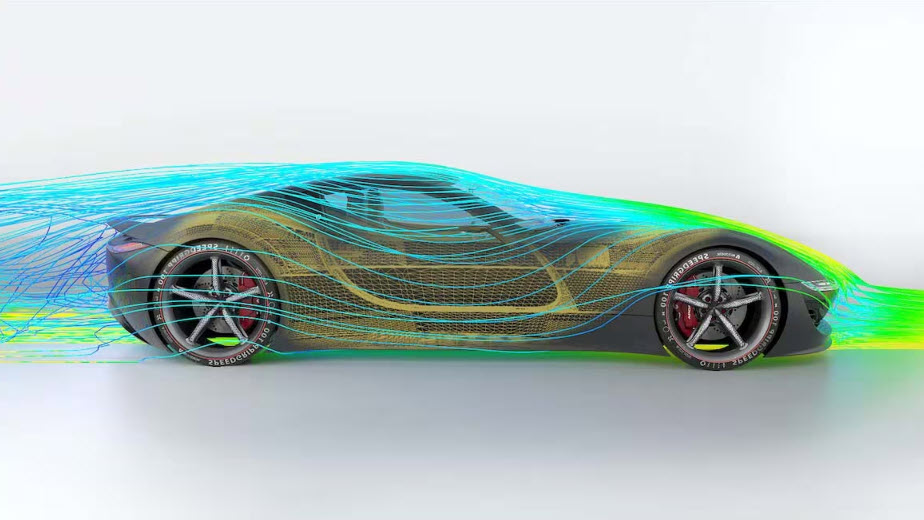

Digital Twin in Manufacturing

A digital twin in manufacturing creates real-time, dynamic virtual replicas of physical objects, systems, or processes, leveraging IoT, AI, and data analytics for detailed simulations and predictive analyses. This technology significantly enhances product design, predictive maintenance, operational efficiency, quality control, and sustainability. In the rapidly evolving landscape of Industry 4.0, the concept of a digital…

Design & Engineering

-

The Role of Mechanical Design Software in Product Development

Mechanical design software is crucial in product development, enabling engineers to create, analyze, and refine products efficiently. Mechanical design software is an indispensable tool in product development. It offers features to streamline and enhance the design process, allowing engineers and designers to create, analyze, and refine their products with precision and efficiency. Autodesk Inventor, a…

Design & Engineering

-

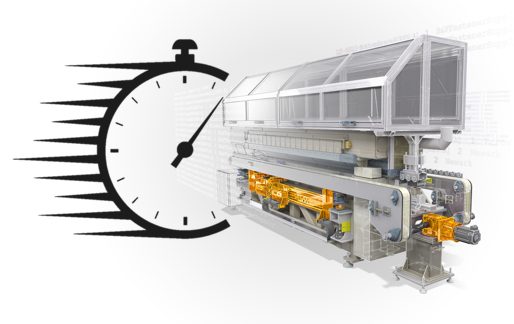

Accelerating Mechanical Design with Autodesk Inventor

Learn how Autodesk Inventor enhances mechanical design by streamlining the process, reducing tasks, and improving precision and efficiency. Mechanical design is an intricate process that requires precision, foresight, and efficient use of tools. Autodesk Inventor is a powerful software that can significantly streamline this process if used effectively. Here are some strategies to accelerate your…

Design & Engineering

-

Simulation Software in Design & Engineering

Discover the value of simulation software in design and engineering, its applications across industries, and how Autodesk Nastran and Autodesk Fusion provide powerful tools for optimizing product design and manufacturing. Through advanced modeling and analysis capabilities, simulation allows for thorough evaluation of designs under realistic conditions, unlocking efficient problem-solving, cost reduction, and product innovation. Let’s…

Design & Engineering

-

2D and 3D Design: Top Workflows with AutoCAD and Inventor

The integration of 2D and 3D workflows using AutoCAD and Inventor enhances productivity, quality, and competitiveness by enabling a seamless design process, improving collaboration, and automating tasks. The integration of 2D and 3D workflows is crucial for enhancing productivity, product quality, and market competitiveness in manufacturing. AutoCAD and Inventor, offer powerful capabilities that, when used…

Design & Engineering

-

Factory Simulation and Virtual Reality in Manufacturing

Factory simulation helps manufacturers achieve efficiency, and precision by enabling virtual modeling, analysis, and optimization of production processes.

Production

-

Starting the Digital Factory

This blog discusses AI and automation in the digital factory, highlighting the benefits of predictive maintenance and real-time data optimization. Explore how Autodesk solutions empower manufacturers to create digital twins, experiment with factory layouts, and collaborate effectively with stakeholders. The digital factory is helping organizations to transform and innovate their factories and operations. Currently, the…

Production

-

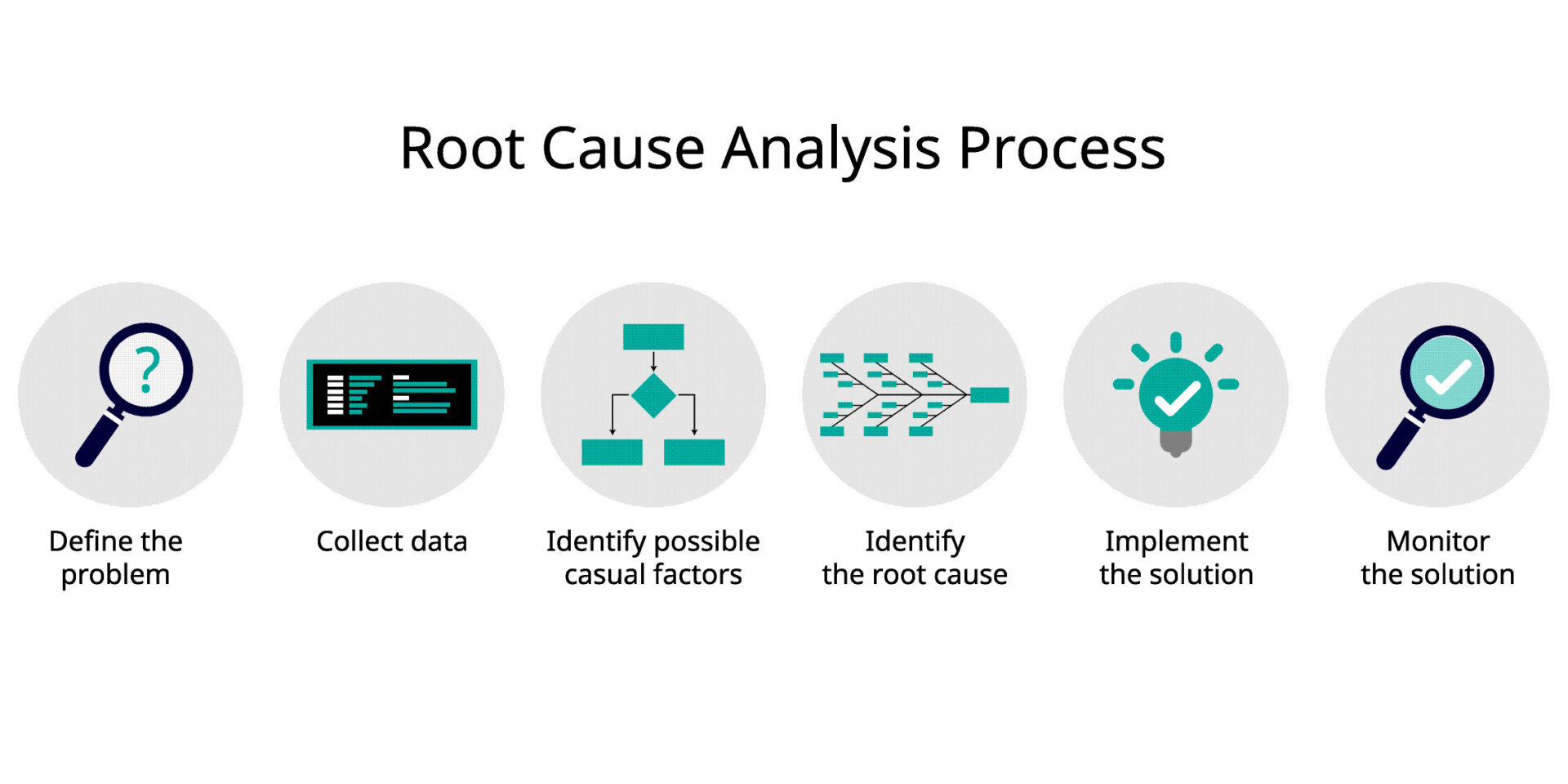

Root Cause Analysis: Unlocking Efficiency and Quality with Autodesk Solutions

Root cause analysis (RCA) is essential in manufacturing for identifying and addressing the underlying causes of problems, thereby improving quality, efficiency, and productivity. Autodesk offers a range of solutions that support RCA by providing tools for data collection, analysis, simulation, and process optimization. Root cause analysis in manufacturing In the manufacturing industry, problems and inefficiencies…

Data & Process