Autodesk Factory Design Utilities

-

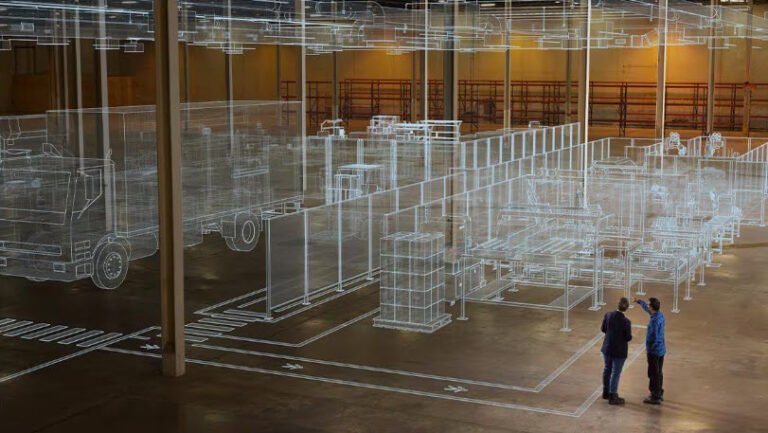

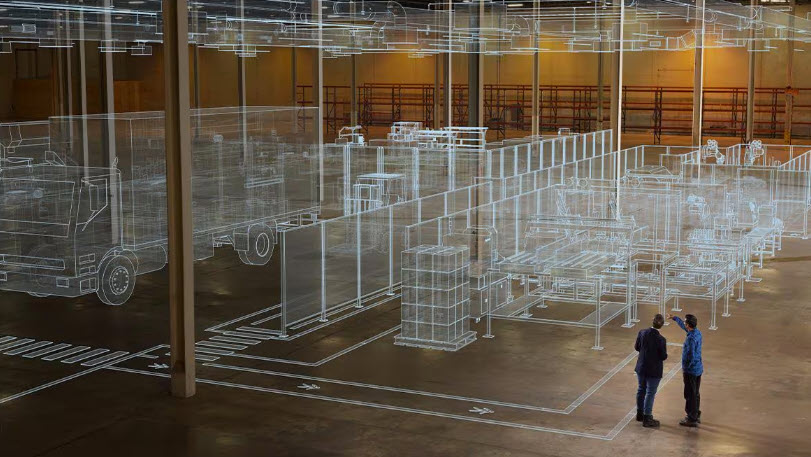

Connecting FDU and FlexSim for End‑to‑End Factory Simulation

Learn how connecting Autodesk Factory Design Utilities (FDU) with FlexSim enables true end‑to‑end factory simulation, improving throughput, reducing risk, and optimizing layout and operations. Production bottlenecks, resource constraints, and unpredictable shifts in demand can derail even the best factory planning. Factory simulation helps address these challenges by revealing how a system behaves under real‑world scenarios…

Production

-

JIT Management in a Digital Manufacturing World

Explore how AI, IoT, and automation strengthen modern JIT management while addressing challenges related to supplier reliability and uncertain demand. As global supply chains become more interconnected, they become more fragile. In this context, successful just-in-time (JIT) strategies require more than traditional lean practices. They now need digital technologies capable of sensing, predicting, and adapting…

Production

-

Unifying Factory Solutions for Smarter Production

Explore how Autodesk’s integrated factory production solutions help manufacturers optimize factory layouts, streamline production processes, and improve operational efficiency for smarter, faster factory production. Autodesk is entering a new era of unified production—one where smart collaboration and digital factory solutions converge to transform how products are designed, engineered, and manufactured across industries. By integrating FlexSim with AutoCAD, Inventor Factory Design Utilities, Vault – and introducing…

Production

-

The Digital Factory: Analytics and Cloud Platforms for Smarter Manufacturing Decisions

Examine how advanced analytics and cloud platforms turn manufacturing into digital factories with actionable insights for agility and flexibility. Learn how Autodesk Factory Design Utilities unifies design, simulation, and collaboration to optimize operations and stay resilient in a competitive and unpredictable market. Manufacturing has reached a stage where traditional approaches are no longer viable. Instead,…

Production

-

Enhanced Efficiency with Just-In-Time (JIT) Tools in Manufacturing

JIT tools significantly enhance manufacturing efficiency by automating and optimizing tasks. Autodesk’s Inventor, Vault, and Factory Design Utilities aid in improving production processes and workflows. Are increasing manufacturing inefficiencies giving you a headache? Just-in-time (JIT) tools can streamline and automate tasks, greatly enhancing manufacturing efficiency. Let’s explore the uses and benefits of JIT tools, specifically…

Production

-

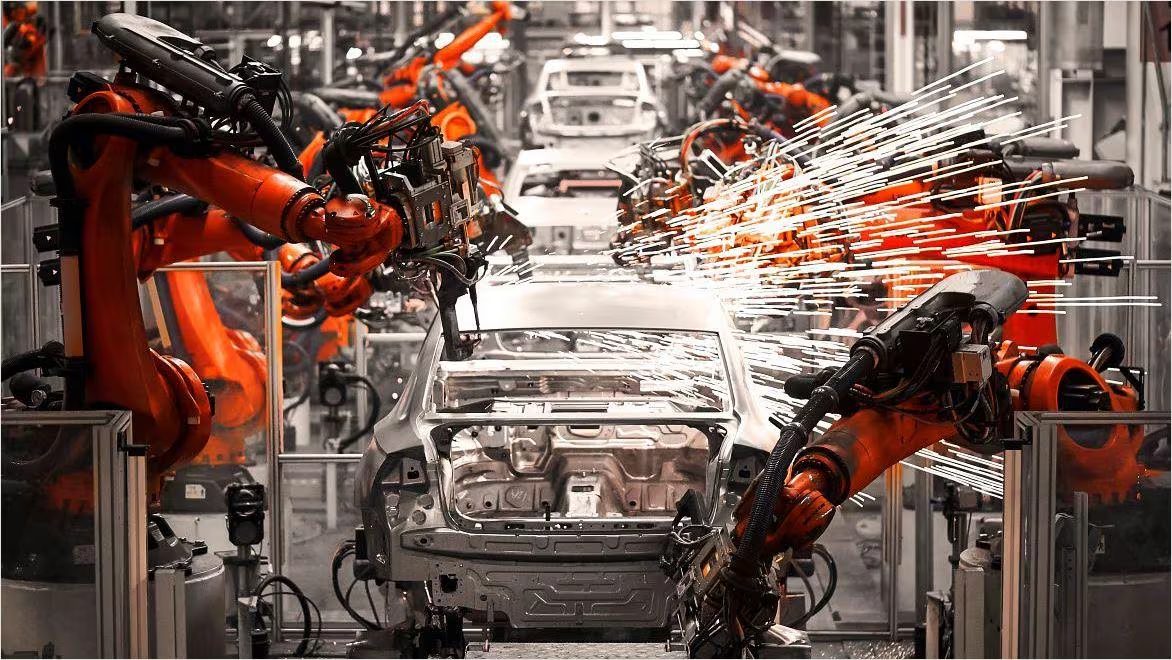

Trends in Industrial Automation: Transforming Manufacturing in 2025 and Beyond

Industrial automation, projected to reach $378.57 billion by 2030, is being transformed by IIoT, Industry 4.0, AI, edge computing, collaborative robots, and 5G. These technologies enhance real-time monitoring, predictive maintenance, and operational efficiency in manufacturing. Industrial automation – key takeaways The manufacturing landscape is changing as emerging technologies reshape how companies approach production, efficiency, and…

Production

-

Digital Factory Virtual Summit 2025

Join an exclusive gathering of industry leaders and executive decision-makers at the EMEA Digital Factory Virtual Summit—your gateway to the future of manufacturing.DATE: 8 October 2025TIME: 11:30 AM CET | 10:30 AM BSTExplore how cutting-edge digital technologies are transforming factories—boosting throughput, enhancing flexibility, accelerating time to market, and advancing sustainability. This is more than a summit; it’s…

Autodesk Factory Design Utilities

-

The Future of Factory Automation: How Simulation Drives Efficiency and Innovation

Advanced simulation tools are shaping the future of factory automation by driving efficiency, innovation, and competitiveness. These tools help manufacturers optimize processes and design layouts, enhance productivity, reduce costs, and stay agile in the face of modern manufacturing complexities. Factory automation is top of mind for manufacturers today, propelling industries toward unprecedented levels of efficiency,…

Production

-

Factory Simulation and Virtual Reality in Manufacturing

Factory simulation helps manufacturers achieve efficiency, and precision by enabling virtual modeling, analysis, and optimization of production processes.

Production

-

Starting the Digital Factory

This blog discusses AI and automation in the digital factory, highlighting the benefits of predictive maintenance and real-time data optimization. Explore how Autodesk solutions empower manufacturers to create digital twins, experiment with factory layouts, and collaborate effectively with stakeholders. The digital factory is helping organizations to transform and innovate their factories and operations. Currently, the…

Production

-

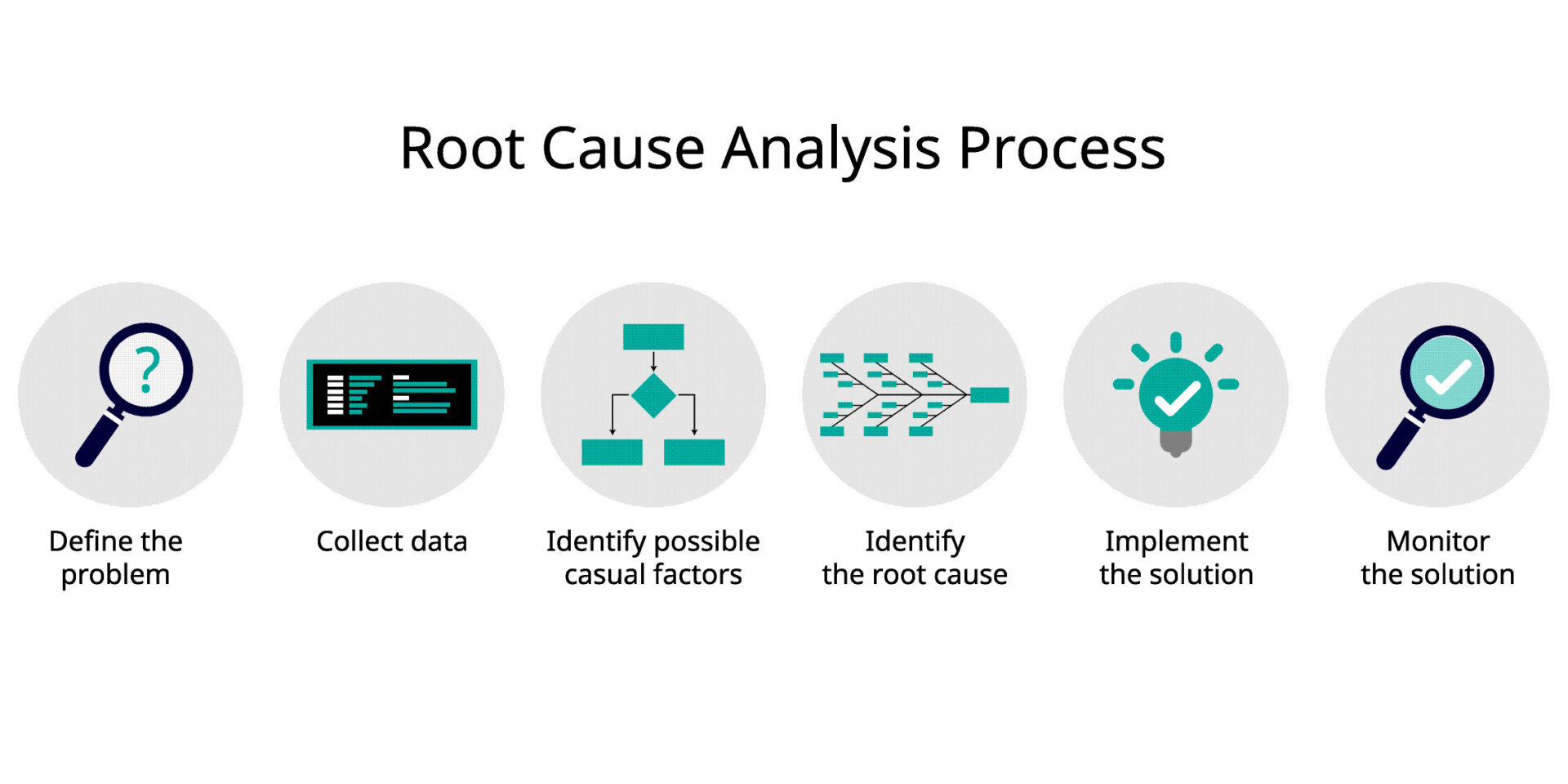

Root Cause Analysis: Unlocking Efficiency and Quality with Autodesk Solutions

Root cause analysis (RCA) is essential in manufacturing for identifying and addressing the underlying causes of problems, thereby improving quality, efficiency, and productivity. Autodesk offers a range of solutions that support RCA by providing tools for data collection, analysis, simulation, and process optimization. Root cause analysis in manufacturing In the manufacturing industry, problems and inefficiencies…

Data & Process

-

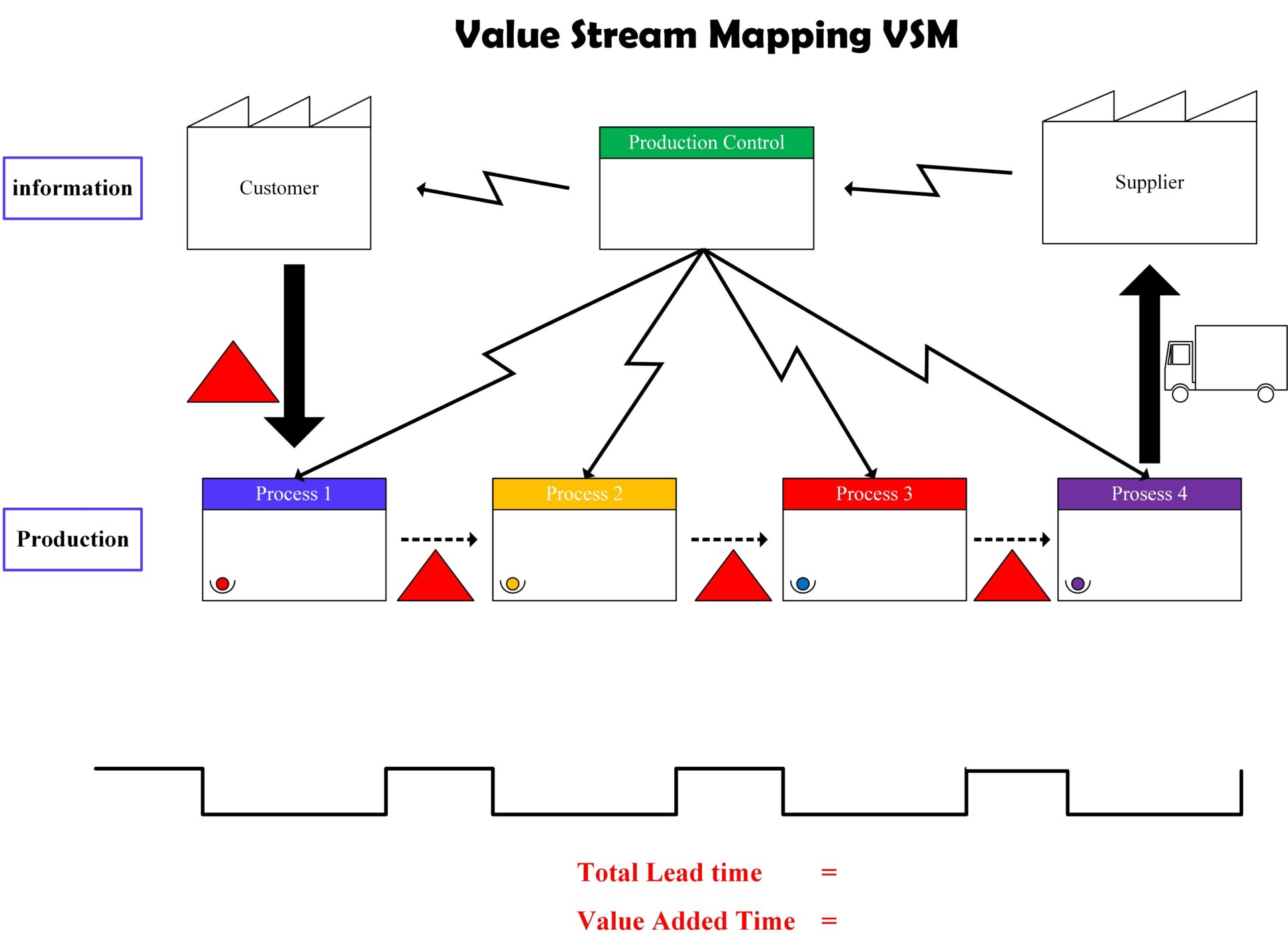

Value Stream Mapping: Transforming Manufacturing Efficiency

Learn what value stream mapping is, the benefits it can have for your business and how Autodesk design and manufacturing solutions can help. Value stream mapping (VSM) is a lean-management method used to analyze and design the flow of materials and information required to bring a product to market. Originating from the Toyota Production System,…

Production