Autodesk Fusion Operations

-

Take Control of your Manufacturing Processes with Customizable User Roles in Fusion Operations

Fusion Operations introduces a Customizable User Roles feature to enhance control over data access and editing permissions, aligning system access with organizational roles and workflows. If you’re already using Fusion Operations to track and schedule your production processes, you know the value it adds to your daily operations. That means a lot of data, often more than a single user needs…

Production

-

JIT Management in a Digital Manufacturing World

Explore how AI, IoT, and automation strengthen modern JIT management while addressing challenges related to supplier reliability and uncertain demand. As global supply chains become more interconnected, they become more fragile. In this context, successful just-in-time (JIT) strategies require more than traditional lean practices. They now need digital technologies capable of sensing, predicting, and adapting…

Production

-

Understanding RTLS: The Role of Real-Time Location Systems in Manufacturing

Real time location systems for manufacturing provide real-time tracking and data integration in order to optimize asset utilization, inventory management, production efficiency, safety, and decision-making. This positions RTLS in manufacturing teams for data-driven success. RTLS for manufacturing In the fast-evolving world of manufacturing, staying competitive means constantly seeking ways to enhance efficiency, accuracy, and productivity.…

Data & Process

-

Smart Factories as Business Imperatives

This article explores how smart factories turn real-time data into business intelligence that drives efficiency and agility. It examines the technologies powering this transformation and how Autodesk solutions like Autodesk FlexSim and Fusion Operations enable manufacturers to optimize performance, sustainability, and profitability through connected digital systems. Factory operators are converting traditional factories into “smart” facilities…

Autodesk FlexSim

-

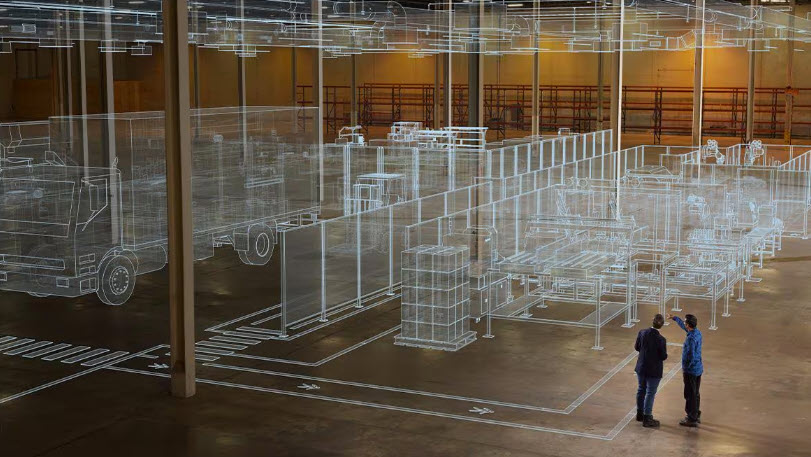

Unifying Factory Solutions for Smarter Production

Explore how Autodesk’s integrated factory production solutions help manufacturers optimize factory layouts, streamline production processes, and improve operational efficiency for smarter, faster factory production. Autodesk is entering a new era of unified production—one where smart collaboration and digital factory solutions converge to transform how products are designed, engineered, and manufactured across industries. By integrating FlexSim with AutoCAD, Inventor Factory Design Utilities, Vault – and introducing…

Production

-

Demand-Driven Success: Lean Production Meets Just-In-Time (JIT)

Lean production and just-in-time (JIT) manufacturing work together to eliminate waste, reduce inventory, and create agile, demand-driven production systems that maximize efficiency, quality, and customer value. Understanding lean production just-in-time (JIT) Manufacturing companies around the world have discovered that lean production and just-in-time (JIT) methodologies represent the most effective approach to eliminating waste while maximizing…

Production

-

Comprehensive Guide to Manufacturing Resource Planning (MRP II)

Manufacturing resource planning (MRP II) helps companies optimize their manufacturing processes, covering everything from materials to labor costs. This guide explains MRP II, its benefits, how it differs from MRP I and how Autodesk Fusion Operations can enhance MRP II. Understanding manufacturing resource planning (MRP II) Manufacturing resource planning (MRP II) is an integrated information…

Production

-

Enhanced Efficiency with Just-In-Time (JIT) Tools in Manufacturing

JIT tools significantly enhance manufacturing efficiency by automating and optimizing tasks. Autodesk’s Inventor, Vault, and Factory Design Utilities aid in improving production processes and workflows. Are increasing manufacturing inefficiencies giving you a headache? Just-in-time (JIT) tools can streamline and automate tasks, greatly enhancing manufacturing efficiency. Let’s explore the uses and benefits of JIT tools, specifically…

Production

-

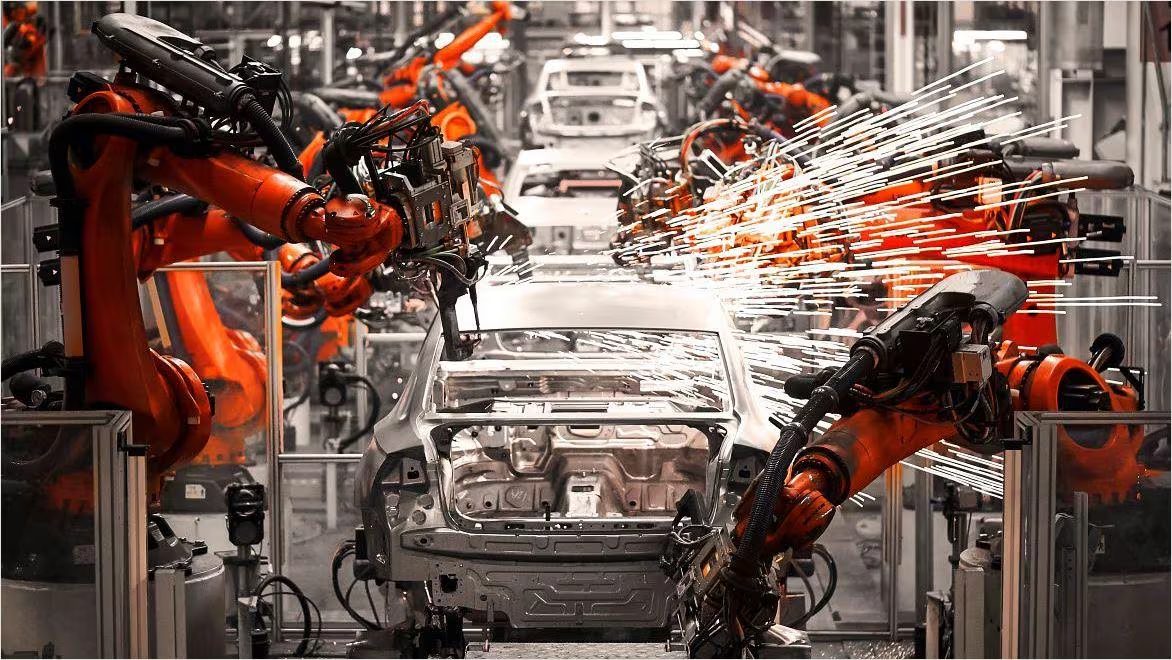

Which Digital Manufacturing Trends Are Changing the Modern Factory?

Explore four major trends in digital manufacturing—automation, digital twins, sustainability, and workforce digitization—and see how Autodesk solutions help factories implement and scale these innovations. Since the first industrial revolution, factories have continued to evolve at a rapid pace. In 2025, factories are increasingly defined by their digital tools and ability to perform data-driven decisions. Currently,…

Production

-

The Future of Factory Automation: How Simulation Drives Efficiency and Innovation

Advanced simulation tools are shaping the future of factory automation by driving efficiency, innovation, and competitiveness. These tools help manufacturers optimize processes and design layouts, enhance productivity, reduce costs, and stay agile in the face of modern manufacturing complexities. Factory automation is top of mind for manufacturers today, propelling industries toward unprecedented levels of efficiency,…

Production

-

The Digital Factory of the Future

Learn how the digital factory of the future is changing manufacturing through intelligent systems and how Autodesk solutions support this evolution with advanced layout and coordination tools. The concept of a digital factory has become the blueprint for future-ready production as manufacturing evolves to be more responsive, sustainable, and efficient. By integrating data, automation, and…

Production