Autodesk FlexSim

-

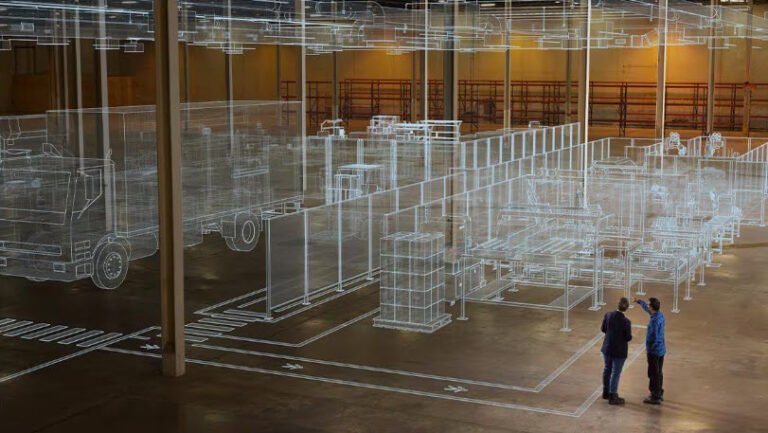

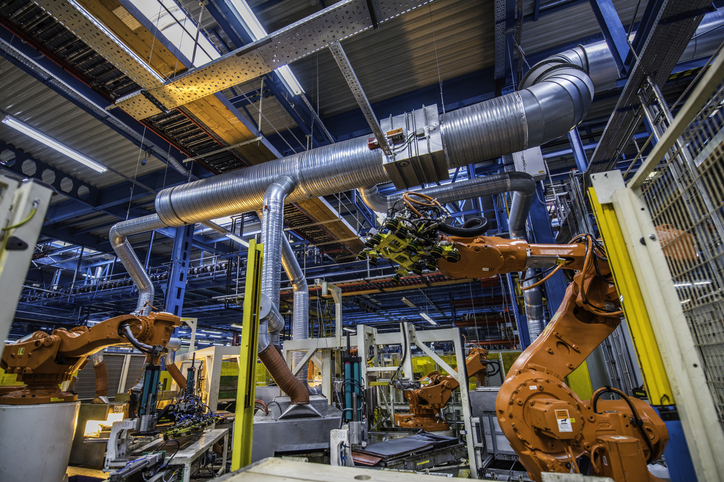

Connecting FDU and FlexSim for End‑to‑End Factory Simulation

Learn how connecting Autodesk Factory Design Utilities (FDU) with FlexSim enables true end‑to‑end factory simulation, improving throughput, reducing risk, and optimizing layout and operations. Production bottlenecks, resource constraints, and unpredictable shifts in demand can derail even the best factory planning. Factory simulation helps address these challenges by revealing how a system behaves under real‑world scenarios…

Production

-

Optimizing Warehouse Throughput with Material Handling Strategies

Discover how optimized material handling strategies—such as zoned presorting, batching, and workflow redesign—can significantly increase warehouse throughput with Autodesk FlexSim. Introduction: Why material handling drives warehouse performance Material handling is one of the most influential factors affecting operational success in today’s distribution centers. In facilities that span hundreds of thousands of square feet, every second…

Production

-

Digital Twin and Discrete-Event Simulation: Driving Efficiency Before the First Machine Starts

Explore how manufacturers use digital twins and discrete-event simulation to boost efficiency before production starts. It covers how simulation models system operation over time and how Autodesk FlexSim supports early decisions, factory planning, and ongoing process improvement. Today, manufacturing teams face important decisions well before installing equipment or starting a production line. To address this,…

Production

-

Digital Simulation and Throughput Optimization with Autodesk

Digital simulation is one of the most powerful tools for helping manufacturers optimize factory throughput. Learn how simulation strengthens planning and how Autodesk FlexSim provides a powerful platform for modeling production behavior and reducing operational risk. Today’s factories contend with blistering timelines, variable demand, and increasing product complexity. With so much pressure on manufacturers, every…

Autodesk FlexSim

-

Smart Factories as Business Imperatives

This article explores how smart factories turn real-time data into business intelligence that drives efficiency and agility. It examines the technologies powering this transformation and how Autodesk solutions like Autodesk FlexSim and Fusion Operations enable manufacturers to optimize performance, sustainability, and profitability through connected digital systems. Factory operators are converting traditional factories into “smart” facilities…

Autodesk FlexSim

-

Discrete Event Simulation (DES): The Engine Behind Data-Driven Manufacturing Decisions [Update 2025]

Discrete event simulation (DES) enables manufacturers to analyze, model, and optimize complex production systems without disrupting real-world operations. As the manufacturing ecosystem grows more dynamic—with variables like supply chain volatility, custom product demands, and automation—DES provides a virtual sandbox for experimentation, forecasting, and cost optimization. How discrete event simulation (DES) & modeling helps manufacturing make…

Autodesk FlexSim

-

Unifying Factory Solutions for Smarter Production

Explore how Autodesk’s integrated factory production solutions help manufacturers optimize factory layouts, streamline production processes, and improve operational efficiency for smarter, faster factory production. Autodesk is entering a new era of unified production—one where smart collaboration and digital factory solutions converge to transform how products are designed, engineered, and manufactured across industries. By integrating FlexSim with AutoCAD, Inventor Factory Design Utilities, Vault – and introducing…

Production

-

Demand-Driven Success: Lean Production Meets Just-In-Time (JIT)

Lean production and just-in-time (JIT) manufacturing work together to eliminate waste, reduce inventory, and create agile, demand-driven production systems that maximize efficiency, quality, and customer value. Understanding lean production just-in-time (JIT) Manufacturing companies around the world have discovered that lean production and just-in-time (JIT) methodologies represent the most effective approach to eliminating waste while maximizing…

Production

-

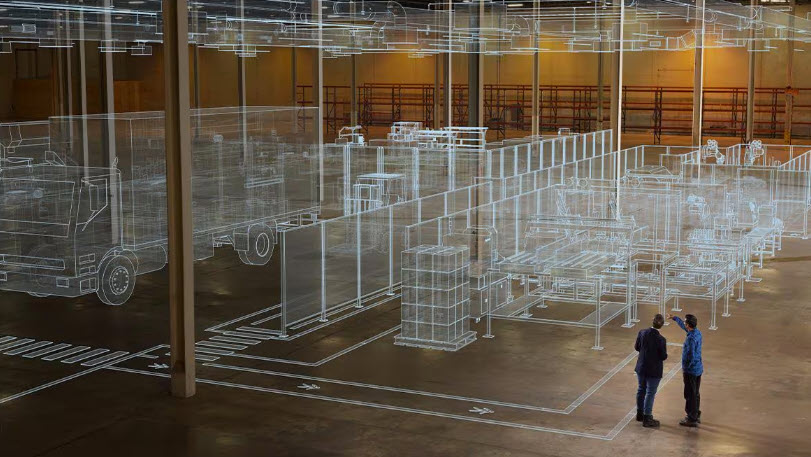

Trends in Industrial Automation: Transforming Manufacturing in 2025 and Beyond

Industrial automation, projected to reach $378.57 billion by 2030, is being transformed by IIoT, Industry 4.0, AI, edge computing, collaborative robots, and 5G. These technologies enhance real-time monitoring, predictive maintenance, and operational efficiency in manufacturing. Industrial automation – key takeaways The manufacturing landscape is changing as emerging technologies reshape how companies approach production, efficiency, and…

Production

-

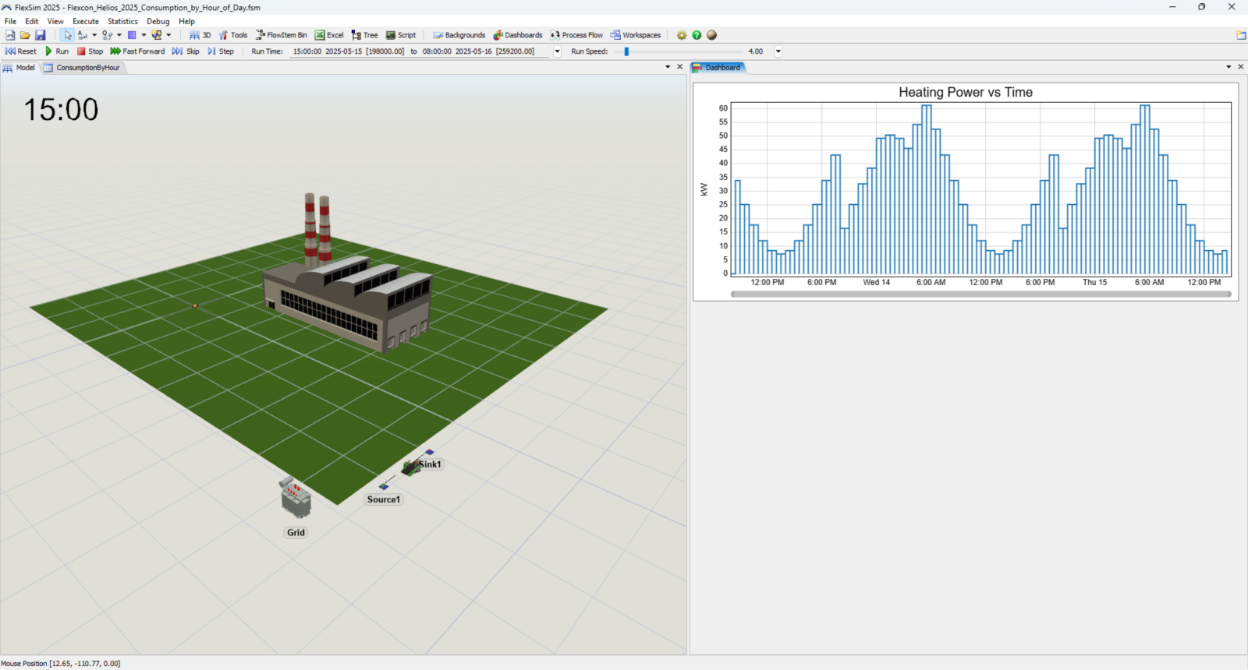

Cut carbon emissions and control energy costs with Flexcon Helios and FlexSim

Flexcon Helios, integrated with FlexSim, offers advanced simulation tools to optimize energy use, reduce costs, and lower emissions, supporting manufacturers in meeting environmental and operational goals. The industrial sector contributes a significant share of carbon emissions and energy consumption. According to the World Economic Forum, global manufacturing accounts for 20% of global carbon emissions and…

Autodesk FlexSim

-

The Future of Factory Automation: How Simulation Drives Efficiency and Innovation

Advanced simulation tools are shaping the future of factory automation by driving efficiency, innovation, and competitiveness. These tools help manufacturers optimize processes and design layouts, enhance productivity, reduce costs, and stay agile in the face of modern manufacturing complexities. Factory automation is top of mind for manufacturers today, propelling industries toward unprecedented levels of efficiency,…

Production

-

Revolutionizing Healthcare with 3D Simulation Modeling

3D simulation modeling, with tools like Autodesk FlexSim, enables healthcare professionals to analyze and optimize patient-based processes. This approach enhances patient care, improves operational efficiency, and achieves better outcomes, which will be crucial for future advancements in the industry. The healthcare industry is one of the most complex and dynamic sectors, requiring constant advancements to…

Production