STRUCMAC ENGINEERING

Autodesk tools and StrucMAC Engineering’s adoption of digital technology transforms their business

Share this story

Summary

Established in 1996 as a precision engineering company in a 100m² facility with only 5 employees, StrucMAC Heavy Engineering began its journey to becoming one of South Africa's leaders in heavy engineering. Today StrucMAC celebrates 25 years in business and boasts a state-of-the-art 14 800m² manufacturing workshop with 200 employees. StrucMAC is a leader in digital transformation and community development in its sector.

Impressive as this incredible growth has been for StrucMAC, it did not come without its challenges. With over 25 years of service StrucMAC has seen it all when it comes to engineering challenges, from the smallest pieces of machinery that need servicing to big 70-ton dump truck buckets, no project has been too challenging or too complex. Despite the impacts of the COVID-19 pandemic, the team at StrucMAC used these challenges to re-think how they operate, maintain output and remain profitable while keeping their team employed.

Image courtesy of StrucMAC Engineering

The Challenge

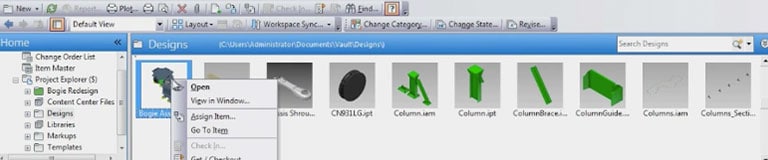

8 years ago, and with only one Autodesk Inventor license, David Emmett, Engineer and Drawing Office Manager at StrucMAC, couldn’t collaborate with his team to review the drawings submitted by customers. This was due to the low quality and lack of detail on the drawings supplied to them.

As a workaround, the team decided that it would be best to reverse-engineer the parts they needed by getting sample parts from customers and accurately measuring and drawing them up. This change led to the organisation’s increased need for Autodesk design solutions, as they quickly realised the valuable contribution to the business’s processes that helped them deliver outputs quicker, with more accuracy and less time spent on the reworking of designs. From concept to the design and manufacturing process, Emmett says that Autodesk’s technology has streamlined the company’s workflow and enabled its teams to work more efficiently.

Image courtesy of StrucMAC Engineering

Speed is of the essence

Once the team were introduced to other Autodesk tools that were available in the Autodesk Product Design and Manufacturing Collection, they were able to use these tools to design and manufacture aftermarket parts for equipment and vehicles and unlock a massive new revenue stream for their business.

The increasing price of materials, machinery, equipment, and skilled labour is a harsh reality for any organisation in this industry. What differentiates StrucMAC from its competitors is how the company responds to these obstacles.

Text-only; 1 column

“What sets us apart is how quickly and efficiently we can turn around and supply products,” says Emmett. “It’s very difficult to continue improving amid the unstable state of the economy. The biggest challenge in this space is finding ways to give our customers value for money while ensuring the same level of precision, quality, and service.”

The industry continues to evolve and adapt to global innovations and increased demand. Staying at the forefront of technology has become a critical component in helping StrucMAC maintain its competitive advantage through innovative thinking, the use of modern machinery and tooling, and investment in workforce skills.

The journey to digitisation

"The next step in the digital transformation journey for StrucMAC was data management. This has become a crucial component for a company which has grown exponentially, not just in project size but also in company size, with large amounts of information flowing between employees."

“The importance of a Common Data Environment (CDE) is clear in the type of work we do and having a data management system in place helps us to generate drawings quicker and easier by referring to older models, something we look forward to achieving with our Autodesk solutions, which include the Architecture, Engineering & Construction Collection, along with the Product Design & Manufacturing Collection, together with the assistance of Baker Baynes.”

—[David Emmett], Engineer and Drawing Office Manager, StrucMAC Engineering

Image courtesy of StrucMAC Engineering

Delivering excellence during a global pandemic

With many other smaller firms closing, there was an influx of employment seekers at StrucMAC, one of very few companies in this sector that managed to remain open. “The skilled labour was there, the work was there”, says Emmett. “There was no reason not to seize the opportunity to grow - especially in the mining industry where StrucMAC has become the go-to service provider.”

Emmett proudly confirms that the growth the company has seen over the recent years can be attributed to its staff’s commitment to learning, skills development, and the early adoption of the latest technology solutions.

"We make use of the most modern and up-to-date digitised production systems, professional planners, machinists, and artisans, and a quality system developed over 25 years to ensure excellent service, quality, and quick project turnaround.”

—[David Emmett], Engineer and Drawing Office Manager, StrucMAC Engineering

Image courtesy of StrucMAC Engineering

Empowering a new generation of engineers.

With a drawing office that has doubled in size, Emmett proudly shares that the draughts people currently in his team are all former students who studied at CTU Training Solutions and the African Academy, a local not-for-profit training centre. These students, who have completed their courses, took up internships at StrucMAC and have used this opportunity to hone their design skills, learn more about the industry and contribute to the community by helping to alleviate youth unemployment.

People development remains a high priority at StrucMAC, which is why the organisation believes in cross-training employees as much as possible, to make them more adaptive to change and more flexible to work on various projects at any given time.

Journey to Industry 4.0 driven by Autodesk

StrucMAC’s long-term goal is to continuously improve workflows and processes throughout their business. With the addition of Autodesk Advance Steel the draughts people at StrucMAC are able to diversify their drawing skills by optimising and automating cutting and processing through their advanced machinery.

By embracing digital transformation as a strategy, StrucMAC Heavy Engineering is well equipped for Industry 4.0, and with Autodesk Gold Partner, Baker Baynes by their side to assist with technology adoption, technical support, training, and implementation, StrucMAC believe they are well prepared for the future of manufacturing.