Research and development teams don’t always get the spotlight, but they play a huge role in where our industry is headed. R&D folks sit at the very forefront of tech development, and this puts them in the best position to anticipate what’s coming next.

It’s always exciting to hear what they have to say, and this episode of Digital Builder allows us to do exactly that. I’m joined by Fope Bademosi, Circular Economy and Construction Researcher at Autodesk, and Lorenzo Villaggi, Principal Research Scientist, also from Autodesk.

Fope and Lorenzo pull back the curtain on what the Autodesk Research team has been working on, shedding light on future-focused projects around AI and sustainable construction.

Here are some highlights from our discussion.

We discuss:

As the team responsible for exploring new technologies, Autodesk Research works years ahead of where the industry is today.

“Autodesk Research explores how technology can be applied to emerging design and make challenges to prepare our industries for the coming future. What's unique about our approach to research is our teams are working five to 10 years ahead in the future across all the industries that Autodesk serves,” explains Fope.

Fope and Lorenzo focus specifically on AECO, and they collaborate with internal and external stakeholders to turn long-term ideas into applied research. One example of this can be seen in the Autodesk Research residency program, which houses a community of innovators from academic, industry, and entrepreneurial sectors.

“This allows us to cross-pollinate ideas that end up being applied research projects. We try to prove and test our workflows on actual construction and design challenges. And the Autodesk Technology Center is where these research projects come to life.”

Beyond working ahead of the curve, Lorenzo says that the ability to test ideas directly with customers sets the team apart.

“We’re in a unique position, and it’s a privilege to be thinking so far ahead in the future. We explore the possibility to test things directly with customers, being right there in the industry, doing research in the field.”

AI is top of mind for any futurist, and the Autodesk Research team is no exception. One of their key focus areas, as far as AI is concerned, is sustainability.

Why? Because the numbers are hard to ignore. As Fope points out:

“We've been thinking a lot about AI for net-zero buildings in the past years or so. And one way to achieve net-zero carbon buildings is to reuse as many materials and buildings,” shares Lorenzo.

According to him, the team has developed two AI innovations that help make reuse more practical and easier to act on. The first is a solution that assesses existing buildings by leveraging limited and multimodal data. The second AI innovation is all about using AI agents to develop low carbon wall assemblies.

Let’s explore these in more detail below.

An AI tool that predicts what’s inside a wall

Have you ever opened up a wall only to be surprised by what’s inside? Let’s say you’re working with an existing structure and are tasked with identifying materials that can be reused. Doing this can be difficult because you rarely have the full picture. Much of what matters is hidden behind walls or ceilings.

This is one of the challenges that Autodesk Research set out to solve.

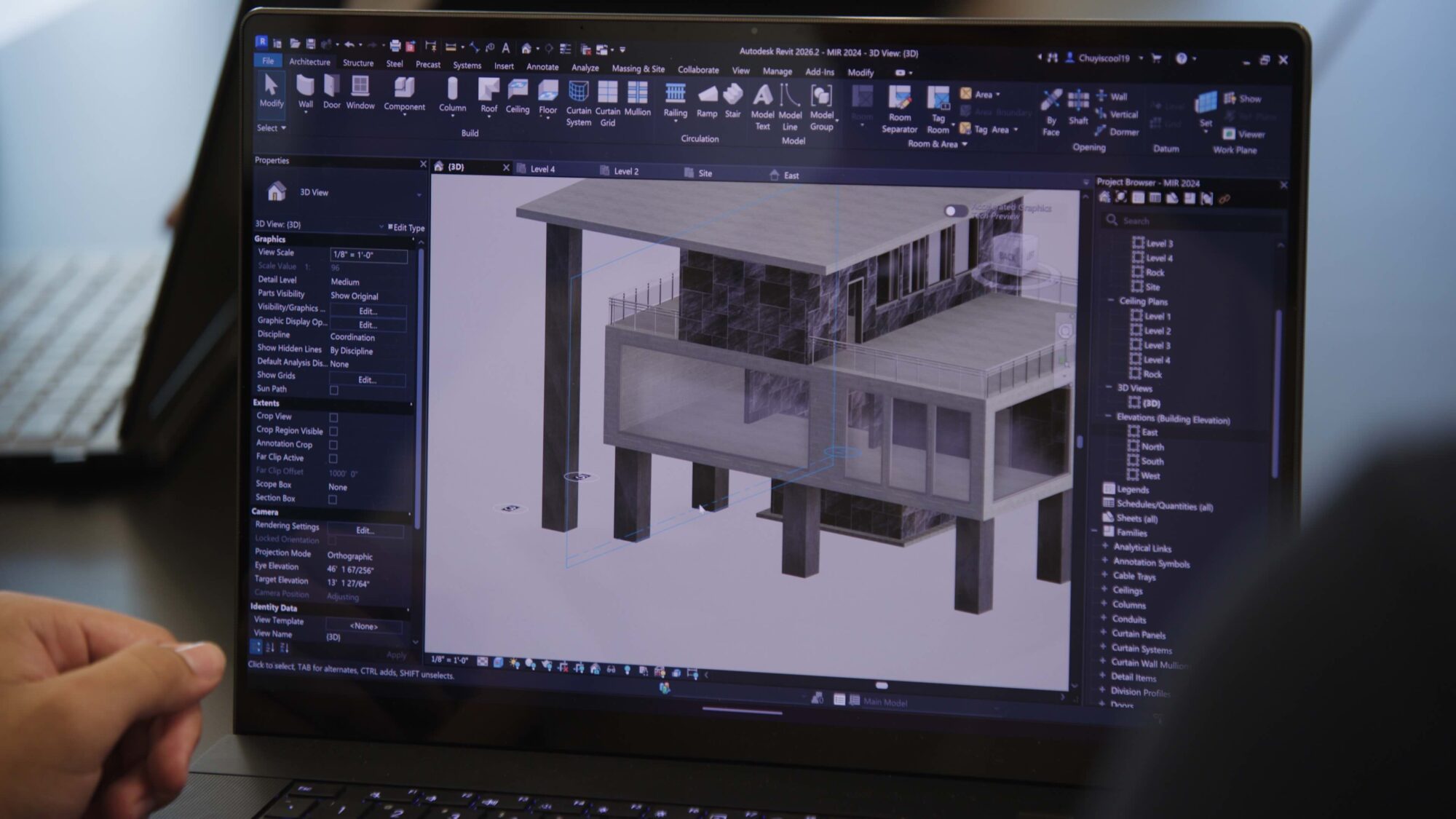

The team developed a prototype that lets users point a tablet at a wall and see, in real time, what materials and systems may be hiding inside, almost like X-ray vision.

"What we're showing here is just the final step of this AI tool that predicts what is inside the wall. It’s the result of a custom large language model workflow we devised. We mix limited and multimodal data together, and this is data that is typically available with existing building projects,” explains Lorenzo.

Beyond simply revealing what’s behind the drywall, the tool is designed to support better decisions much earlier in the process. And according to Lorenzo, this tool is just one step in a bigger pipeline of innovations that help teams move from assessment to action.

“We start with step one, which is predicting what is inside the walls or the material composition of an existing building. And then we derive an inventory of materials. From there, it’s about helping teams make use of the information, so they can start designing low carbon assemblies that involve reusable materials,” Lorenzo explains.

“With all of this in mind, we believe that this can really help us achieve our goal, which is ultimately helping architects achieve low carbon futures,” he adds.

In addition to sustainability, the tool can also enhance the crew’s safety. Fope points out that existing buildings often contain materials crews would rather not discover the hard way.

"I think we also see a future where the tool becomes used on projects and it's able to also predict and identify the presence of hazardous materials. We're talking about old buildings that have been around before LED and asbestos were forbidden. That could also evolve into a tool like that," she says.

An AI workflow for low carbon assemblies

Once the team understands what materials exist inside a building, the next question is obvious. What do you do with all of it? That is where the second AI innovation comes in.

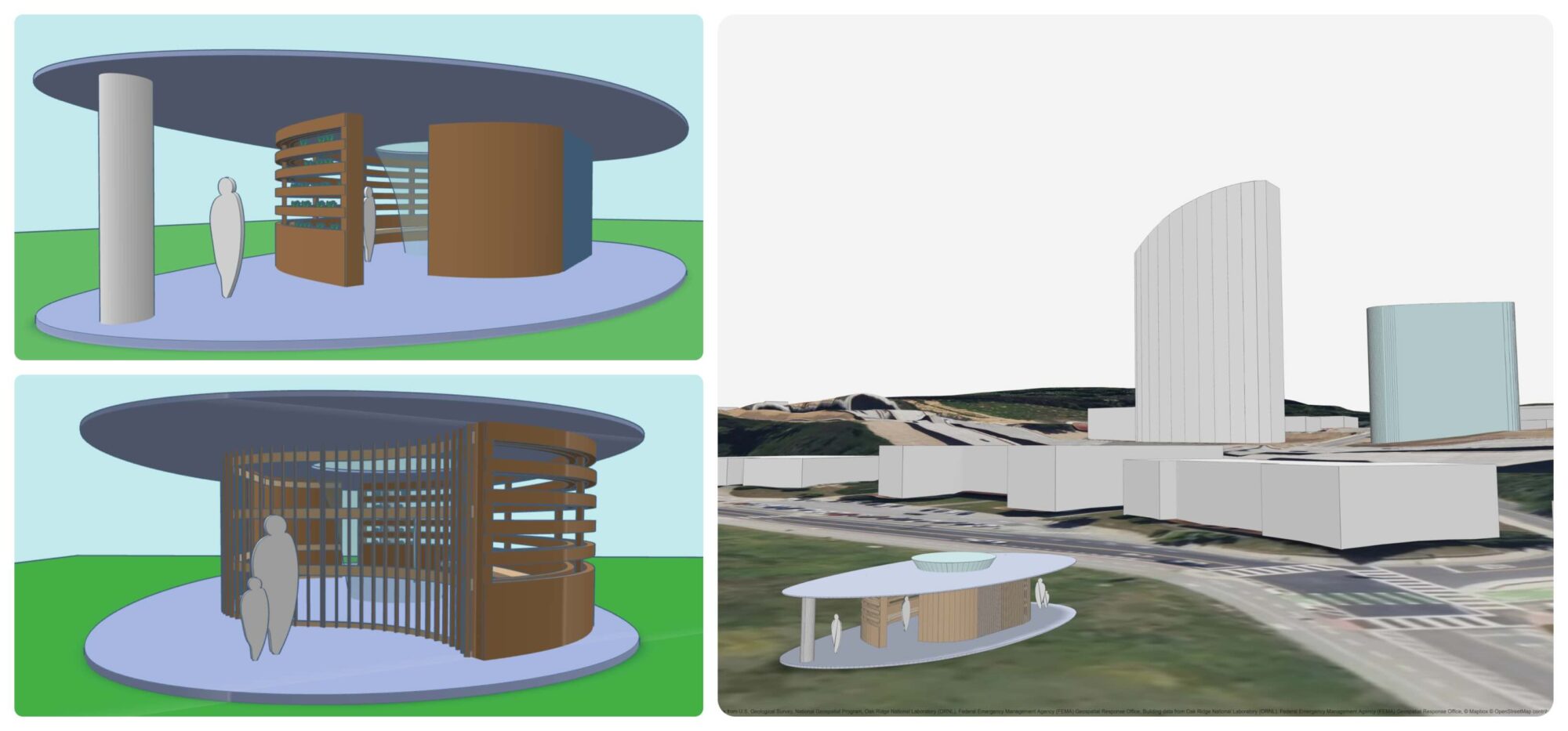

This part of the research focuses on designing low carbon assemblies that make use of reclaimed materials, not just in theory but in practice. Fope describes it as the third step in a broader workflow, one that moves teams from insight to action.

“This is step three of our workflow, where we’re leveraging AI to be able to generate and design low carbon assemblies that integrate these existing materials,” she explains.

The process starts with intent. Users prompt the system with what matters most for their project. That could be cost, carbon reduction, performance targets, or a mix of all three. They also define project requirements, such as insulation values and fire ratings. From there, a group of AI agents goes to work.

“It’s a multi-step agent process,” Fope says. “You have a supervisor agent, a research agent, the designer, and others. Based on the user intent and the project requirements, it comes up with the best possible new design that integrates some existing materials.”

The system does not assume everything should be reused. New materials still play a role, especially when performance or code requirements demand it. The difference is that the AI actively looks for lower carbon options. It pulls from databases like 2050 Materials and EC3, giving teams access to EPDs and performance data for materials such as cork or mycelium-based products.

“It also gives you all the information like the carbon calculation, the performance ratings, and all of that,” Fope explains. “So, it gives you different options. You’re able to pick what’s best for your project.”

Fope also stresses that the designer stays in control. “This is an iterative cycle. It’s not final,” she says. “The decision lies in the hands of the designer.”

Under the hood, those decisions are shaped by multiple agents working together. Lorenzo describes it as a collaborative loop between humans and machines.

“We’re really interacting and collaborating with the machine,” he says. “We’re human agents working with machine agents. You can say, ‘I’d like to swap this with something less carbon intensive,’ and the agents go back to work.”

The goal is not automation for its own sake. It is about giving teams better options, faster, and making low carbon design a practical starting point rather than an afterthought.

Digital Builder is hosted by me, Eric Thomas. Remember, new episodes of Digital Builder go live every week. Listen to the Digital Builder Podcast on:

or wherever you listen to podcasts.

It’s no secret that the labor shortage is keeping many construction pros up at night.

According to the 2025 Autodesk State of Design & Make: Construction Spotlight report, 53% of construction leaders cite lack of skilled talent as a major or moderate concern, and 55% say it’s a barrier to growth (up from 40% in 2024).

These numbers aren’t surprising. Leaders know that having talented teams in their corner is a make-or-break factor, which is why attracting and retaining skilled workers has become a top priority.

This is where technology comes in.

When evaluating employers, today's workforce is paying close attention to the tools they’ll use and the opportunities they’ll have to grow. So, if your firm has a solid tech stack and clear paths for learning and development, you’re far more likely to attract people who want to build a career, not just take a job.

There are several reasons why talent is so tight in the construction industry. One of the major ones is retirement-driven labor loss. Seasoned construction professionals who are exiting the industry are leaving a skills gap that’s hard to fill.

Industry data backs this up: Autodesk research shows that 63% of leaders view the aging workforce as a significant concern.

But it’s not just about people leaving. Not everyone today has the know-how they need to succeed. As digital tools and data-driven processes become part of everyday construction workflows, the current workforce is being asked to adapt to new ways of working.

On top of that, demand for AI and digital fluency is rising fast. In fact, 47% of leaders say AI skills will be a top hiring priority in the next few years.

Technology may not be the first thing that comes to mind when it comes to talent shortage solutions. After all, wages, benefits, and jobsite safety still need to come first.

That being said, technology does play a significant role in shaping how construction firms attract and keep talent. Consider the following.

The youngest people in today’s workforce grew up in a world where digital technology was always within reach. From smartphones to social media, technology has shaped how they communicate and go about their day. Being digital-first is the norm in pretty much every aspect of their lives, and they expect their workplace to be just as modern and connected.

It’s no wonder then that digitally mature firms have an advantage when it comes to attracting younger workers. Based on our findings, 82% of digital leaders in construction actively attract young talent, compared to 62% of emerging users and 55% of beginners.

This tells us that modern tools do more than improve productivity. They signal that a company is forward-looking and willing to invest in tools that make employees' lives easier.

Technology also supports broader diversity goals across the industry. Digital tools can reduce physical barriers, create more flexible roles, and open doors to people who may have been excluded from construction in the past.

That matters, especially as 64% of organizations say they’re aiming for a more diverse talent pool.

Firms that invest in technology can be better positioned to attract talent from different backgrounds and build more inclusive teams.

Being a tech-forward firm requires taking intentional steps and real follow-through. Here’s what to keep in mind.

Digitally mature firms don’t just have the latest tools; they also foster a culture of adaptability and innovation. You can strive to adopt the latest technology, but if the underlying culture is rooted in resistance to change, then implementing tech (and ultimately attracting and retaining fresh talent) will be an uphill battle.

That’s why it’s important to take an honest look at how your teams deal with change and technology, and then assess whether there’s an opportunity to shift people’s mindset and approach.

You can have the shiniest tech, but if it’s not easy to use, then adoption will fall flat. So, make it simple for folks to get started and succeed without a steep learning curve.

Accomplishing that starts with the right tools. When your tech solutions are intuitive and easy to pick up, adoption—even enthusiasm—will quickly follow.

Nothing motivates people to change faster than seeing their peers succeed. Spotlight employees who embrace new tools and show real results. From there, let those wins spread naturally across teams.

New technology sticks when people understand the why behind it. Bring leaders, managers, and frontline teams into the conversation early. Share clear goals, listen to feedback, and show how the tools make day-to-day work easier.

Make sure obtain buy-in from all levels. Doing so will pave the way for smoother implementation.

Internal training plays a big role in closing today’s skills gap. In fact, 64% of construction leaders say they’re implementing continuous learning programs. At the same time, 44% say they lack the resources to design those programs, up 10 points from the previous year.

The takeaway here is clear: training works, but it needs structure, leadership support, and the right tools behind it.

It’s also worth noting that your learning programs shouldn’t just train people for the tech they’re using today. They should also prepare teams for what’s coming next.

Future-ready construction firms are already investing in AI and digital skills that will matter tomorrow. That might start with basic data literacy or hands-on experience with AI-powered tools.

Over time, it creates a workforce that feels confident in adapting to change rather than reacting to it. This approach doesn’t just protect your business. It gives employees a reason to stay and grow.

Ready to leverage tech to attract and retain construction talent? Here are the steps you can take to steer your org in the right direction.

It’s time to rethink the role of technology in your firm. Yes, the right tools can streamline your operations and improve project workflows. But beyond that, technology can also be leveraged to attract and retain talent.

Firms that invest in modern tools, ongoing training, and a culture that supports learning are better positioned to compete in a tight labor market. The companies that win won’t just fill roles. They’ll build teams that want to stay, grow, and help move the industry forward.

Walk any active jobsite and you’ll see the same pattern: constant motion, evolving conditions, and thousands of decisions being made in real time. Construction is one of the most dynamic data-rich environments in the world, yet it has historically been one of the hardest to understand. Teams take thousands of photos on their smartphones, record observations, and document progress across drawings, forms, and reports, but without a way to make sense of all that information, teams are often left without a clear picture of what’s actually happening.

In recent years, AI in construction has been positioned as the solution to this complexity. But most of the advances people talk about – large language models, document summarization, chatbot-style assistants – are built for text. They’re designed for office workflows, not the jobsite. Construction, however, is a reality-first industry. The most important information isn’t buried in a paragraph; it’s visible on the slab, in the walls, and across constantly changing site conditions.

That’s why one of the next biggest transformations in construction will come from Spatial AI – intelligence that understands space, movement, and context in the physical world.

Over the last decade, construction teams have embraced reality capture: 360° cameras, drones, smartphones, and laser scanners. These tools created a visual record of jobsites, but capturing data isn’t the same as understanding it. Without intelligence, huge volumes of images turn into digital clutter.

Spatial AI changes that. It allows systems to:

This is the foundation of what we call visual intelligence – a shift from collecting images to using them to make timely, confident decisions. Instead of asking teams to read through logs or interpret scattered notes, visual intelligence uses imagery, spatial context, and AI to answer questions instantly: What’s here? What changed? What needs attention? Instead of describing conditions, AI will simply show them.

The goal is to give teams a way of working that mirrors how they already operate – by looking, deciding, and getting things done.

And because many builders use Autodesk Construction Cloud, now part of Autodesk Forma, as their system of record, tools like OpenSpace integrate directly with Autodesk Build – syncing drawings, issues, and photo documentation to keep office workflows aligned with verified, reality-based intelligence from the field.

Language models excel at creating summaries and documents, but construction problems are spatial problems:

These aren’t questions you answer by predicting the next word in a sentence. You answer them by understanding physical reality.

Spatial AI does what language AI cannot. It builds a coherent understanding of the jobsite: how rooms connect, how materials evolve, where teams are working, and what’s changing day by day. With that foundation, entirely new categories of field workflows become possible.

One of the greatest breakthroughs enabled by spatial AI is AI Autolocation – a technology that turns the phone in your pocket into a real-time indoor positioning device.

GPS stops working once you step inside a building or facility. Beacon systems are expensive to set up and maintain. And, jobsite conditions are simply too unpredictable for most indoor location systems to hold up.

AI Autolocation takes a different approach. It uses:

As you move through the building, the system matches your phone’s signals to a constantly updating site map. The result is accurate, evolving indoor positioning – no special hardware required.

When location becomes automatic, workflows that used to be painful suddenly become fast and unambiguous:

This is where spatial AI becomes a true system of work, not just a source of data.

Construction has long relied on forms, text fields, and manual reports, despite the fact that jobsites are inherently visual. Image-first workflows flip that dynamic. The smartphone becomes the front end of the jobsite – not just for documentation, but for action.

With spatial AI and features like AI voice notes, teams can simply talk through what they’re seeing, and the system fills in assignee, due date, description, and location, automatically. It’s fast, natural, and aligned with how field teams actually operate.

And because visual intelligence organizes imagery by place and time, teams get instant clarity to questions like:

These aren’t abstract queries; they’re spatial questions. The answers come from imagery anchored to real-world context.

Something powerful happens once teams adopt spatial AI. Every 360° walk sharpens the positioning model. Better positioning makes issue logging faster. More issues create richer context for progress tracking, and better progress tracking strengthens decision-making – all of which encourages more capture.

This is the flywheel of visual intelligence: more capture → more intelligence → more value → more capture.

Crucially, none of this works without one principle: ease of use. Technology only matters if the field actually uses it. The most impactful systems don’t demand training, rework, or new behaviors; they slot into existing rhythms: walk, look, talk, act.

AI Autolocation is a major step forward, but it’s also a foundation. As visual intelligence evolves, the real opportunity is helping AI understand not just what it sees, but where it is and why it matters.

Over time, we expect the jobsite experience to evolve in ways that feel more supportive and intuitive for builders. AI will become:

None of this replaces human expertise. Instead, it strengthens it to give builders a clearer, real-time understanding of their projects so they can make faster, more confident decisions.

Visual intelligence is ultimately about creating a jobsite where information flows naturally, insights come faster, and teams can focus on what they do best: building.

The construction industry doesn’t need more dashboards or text-based analyses. It needs tools that understand the jobsite the way builders do: spatially, visually, and in real time.

Spatial AI is the backbone of that shift. It turns the jobsite into a living information system – always visible, always current, and never in doubt.

AI has officially moved past the hype phase in construction, and the reality is a bit more nuanced than the headlines suggest.

As we've found in Autodesk's State of Design & Make: Construction Spotlight report, AI continues to be top of mind for construction leaders. Early adopters are using AI to help them analyze more variables, move faster during design and planning, and reduce manual work.

That said, folks aren’t as enthusiastic about AI as they were a year ago, and we found that just 32% of construction leaders say they’ve met or are close to meeting their AI goals.

Regardless of how you feel about AI, it’s definitely here to stay. Firms that have a solid grasp of where the technology is heading will be better equipped to harness AI effectively in 2026 and beyond.

With that in mind, we reached out to 25+ construction experts to get their take on the AI construction trends that will shape 2026.

Take a look at their input below.

"AI is becoming indispensable in our industry, although it is still not fully structured. By 2026, AI agents will be more common and widely democratized. I expect AI usage to become more standardized, supported by structured libraries. AI will also enable stakeholders to take advantage of multiple options during the design stage. The client, the architect and the contractor will be able to generate and simulate several design alternatives with a single click and select their preferred option based on specific criteria.

The growing reliance on cloud services might quickly lead to saturation, creating challenges with connectivity and data security. This will push companies and authorities to work on-premises and continue building data centers to maintain data sovereignty. When the cloud keeps growing, we shouldn’t be surprised by the rain. We just need to be prepared for it. AI remains highly energy-intensive and will need to be used wisely."

"In 2026, AI will make the biggest impact in everyday project management and field operations. Instead of feeling like a separate tool, AI will become a built-in assistant that quietly supports teams by summarizing RFIs, drafting meeting recaps, organizing punch lists, and identifying schedule or cost risks earlier than before. This will help project managers and superintendents spend more time making decisions and less time processing information.

AI will also improve accuracy and visibility on the jobsite. Tools that combine AI with reality capture and model-based workflows will help teams understand what has been installed, what is missing, and where potential issues may be forming. This will reduce rework, improve quality, and support more reliable progress tracking.

Another major shift will be the accessibility of AI for smaller firms. As AI becomes easier to use and more integrated into existing platforms, companies of all sizes will be able to improve coordination, documentation, and risk management without adding more administrative burden."

Steven Bloomer

GHD

"In 2026, I expect AI to be far more embedded in day-to-day project delivery, not as a standalone feature, but as a practical layer that supports faster decisions, cleaner data, and smoother coordination across teams.

One of the biggest changes I see coming is how people interact with project information. Instead of switching between platforms or digging through documents, AI will make it possible to simply ask for what you need and receive it instantly, drawings, specifications, past decisions, or model updates. This shift will cut out a lot of unnecessary searching and reduce delays.

I also believe AI will play a larger role in keeping data consistent and complete. It will quietly handle routine checks, highlight gaps, and keep information aligned across disciplines. Designers, engineers and construction teams will spend more time focusing on what matters, problem-solving, while AI manages the background housekeeping."

"AI is already embedded in construction workflows today, and its role will continue to expand in 2026. AI chatbots will remain a powerful tool for everyday tasks such as summarizing documents and assisting with communications—making routine work faster and more efficient. At the same time, I expect to see progress in domain-specific applications. Generative AI will continue to be leveraged for automated creation of parametric design alternatives.

As organizations invest in enterprise AI adoption, priorities will shift toward transparency, governance, and adaptability. There will be growing demand for clear AI performance evaluation workflows, robust support for training and customization to meet organization-specific needs, and strong measures for cybersecurity and data privacy. Despite these advancements, the human element will remain indispensable, and human oversight will continue to play a critical role."

Hammad Chaudhry

Cupix

“In 2026, AI systems for construction are going to start to draw more on spatial context–in other words, accurate captures of the world around us. Most AI systems today have been trained on textual data (documents, schedules, structured records), but not visual data. They can optimize a plan, but can’t detect if the plan is executable or not based on site conditions. The result is often insight that looks correct on paper but fails in the field.

This is where spatial grounding starts to matter. When AI systems are connected to visual and spatial data from the job site, they gain a form of situational awareness. They can begin to reconcile what the schedule says with what the site shows. That does not magically solve execution, but it closes a critical gap between digital intent and physical reality.

This feels like the missing link in many AI stacks today. Not more intelligence in isolation, but intelligence grounded in what is actually happening. In that sense, spatial AI is less about prediction and more about verification. Less about replacing judgement and more about scaling it.”

"In 2026, AI will transition from experimental to essential becoming a foundational layer of modern construction operations. Project teams will increasingly rely on AI to read drawings, analyze field data, monitor inspections, summarize reports, and surface early indicators of risk. This shift will allow teams to spend less time compiling information and more time making informed decisions.

Predictive capabilities will accelerate. AI will help identify schedule impacts, procurement risks, and coordination challenges before they materialize, improving planning accuracy and strengthening project outcomes. The value will not be automation alone; it will be the ability to anticipate issues early enough to act. Ultimately, AI will enhance, not replace, the construction workforce by accelerating decision-making and capturing the expertise that sustains successful projects."

"The use of AI tools will create a significant bifurcation—companies that adapt will see better returns in 2026, with that advantage compounding through 2027 and beyond. 2026 marks the shift from AI as a 'future trend' to 'industry baseline.' Firms that fail to adopt risk losing contracts to competitors who deliver faster, safer, and more sustainably. Early adopters will capture a disproportionate value as AI scales from pilots to production deployment, establishing competitive moats that will be difficult to overcome."

"Perhaps I’m too pessimistic, but I don’t believe AI will be terribly transformative in construction in 2026. I regularly tell people that training AI is akin to educating a child – and AI for construction is still, in my opinion, too early in its training fulfill the big promises being made by the tech sector. That said, as AI is more heavily relied upon, I think concerns around legal liability and intellectual property will help the construction industry focus on how to best shape its use of AI technology going forward."

"I’m predicting a major shift in how we trust, adopt, and ultimately depend on AI in 2026. AI is already helping us analyze data, automate tedious takeoff tasks, and even forecast outcomes. That impact grows exponentially when all project data—from every stage of the construction lifecycle—lives in one connected environment.

This year’s customer conversations have reinforced a key insight: AI’s next frontier isn’t just doing tasks for us but helping teams understand their projects more deeply and far faster than ever before. Traditionally, “learning a project” meant hours of studying drawings, reviewing models (when available), performing takeoffs, hunting down updated costs, and combing through massive spec books.

In 2026, AI will start transforming that process. It will digest these documents, summarize what matters, surface actionable insights, and highlight every scope area that needs to carry a cost. The anxiety of missing something in a bid—the highs, lows, and second guessing—will become a thing of the past."

"On the AI side, my view is simple, you either get on the bus, or you get left standing at the stop. The last time the industry saw this level of hesitation around new technology was when the internet showed up, and anyone who resisted it found themselves playing catch-up for years. I do not believe AI replaces expertise, but it absolutely accelerates it. I use AI to generate a fast, accurate foundation, then I layer in the human judgment, constructability awareness, and project nuance that only experience provides. The companies that figure out how to blend the speed of AI with the decision-making of real builders will outperform the rest, and they will do it at scale."

Emmanuel Graves

Autodesk

"In 2026, AI will continue to move from being a buzzword to becoming a differentiator in how contractors and project teams are awarded projects. Owners and general contractors will seek partners who can demonstrate how AI is embedded into project workflows—from preconstruction through operations and closeout. Teams that can leverage AI to reduce risk earlier, streamline operations, and improve schedule accuracy will stand out, shifting industry norms from reactively putting out fires to proactively driving decisions.

As the return on investment from AI becomes clearer, the role of AI consultants and internal specialists will continue to grow. These roles will help organizations train AI on project-specific data and simplify how AI integrates into existing systems through technologies like Autodesk MCP Servers. This shift will move teams beyond generic, chat-based tools toward AI agents that can audit documents, review plans, and prepare project information—allowing teams to review and validate deliverables while remaining grounded in trusted project data that resides in a single source of truth."

"By 2026, I see AI taking a central role across architecture, engineering, construction, and real estate, becoming a trusted partner from the earliest stages of a project. AI systems will help clients generate project requirements, technical specifications, and BIM-driven facility-management criteria based on a deep understanding of the business' needs and historical facility data. These integrations will ensure buildings' digital information are delivered with strong interoperability and seamless integration across facilities management platforms, digital twins, and operational systems.

Beyond construction, AI will start to reshape real estate through precise market analysis, portfolio optimization, strategic planning, and predictive insights into demand, risk, asset performance, and sustainability trends. These systems will synthesize financial data, spatial analytics, and user behavior to support smarter decisions across the property lifecycle."

Artificial intelligence is moving rapidly from experimentation to operational advantage across the construction lifecycle. In 2026, leading organisations are applying AI not as a standalone innovation, but as a practical layer that improves predictability, safety, and decision-making across planning, design, and delivery.

AI-powered scheduling, forecasting, and risk analysis are enabling teams to predict schedule delays, resource constraints, and cost impacts far earlier than traditional methods, allowing for proactive intervention rather than reactive recovery. In early project stages, generative design is accelerating optioneering by automatically producing multiple alignment, grading, and routing scenarios that balance cost, carbon, and regulatory constraints, making decisions faster and more evidence-based.

On-site, AI-driven safety monitoring uses computer vision from cameras and drones to identify unsafe conditions, PPE non-compliance, and hazardous behaviours in near real time, helping reduce incidents before they escalate. AI is also transforming quality management by comparing LiDAR and drone scans against design models to automatically detect defects and deviations early, minimising costly rework. Across commercial workflows, machine learning–based quantity extraction automates takeoff from PDFs, DWGs, IFCs, and point clouds, significantly reducing manual effort and improving the accuracy and consistency of estimates.

"In 2026, artificial intelligence will move from isolated experiments to fully integrated, mission-critical workflow tools that function as the nervous system of the modern job site. AI will be used across all project roles to improve work experiences and enable better, faster decision-making through data-driven insights, significantly improving project certainty through advanced prediction and scenario planning. Project teams will move beyond static Gantt charts to dynamic, AI-driven “what-if” analysis, allowing planners to quickly test schedule disruptions, resource reallocations, and sequencing adjustments. Cost and workforce forecasting will also become more accurate, with AI models trained on vast historical datasets enabling better conceptual and detailed estimates as well as data-driven resource planning.

On the job site, AI will increasingly focus on safety, quality, and productivity, with computer vision systems automatically detecting safety violations in real time, reality capture tools comparing as-planned versus as-built conditions, and robotics—particularly collaborative robots—taking on repetitive and high-risk tasks alongside human crews. Ultimately, the true value of AI in 2026 will lie in its ability to connect previously siloed structured and unstructured data."

"During 2026, AI will be deeply integrated into core construction workflows rather than used as a standalone tool. We’ll see AI automating model-based coordination, generating takeoffs, optimizing schedules, and analyzing progress through image recognition and sensor-based data. AI assistants will play a major role—acting as virtual project engineers that can answer technical questions, track daily tasks, detect safety risks, and automatically produce reports.

With predictive analytics powered by digital twins, teams will be able to identify delays and cost overruns months earlier and respond proactively. Instead of replacing professionals, AI will enhance human decision-making and free project teams from repetitive administrative work—resulting in safer, faster, and more predictable project outcomes."

"AI becomes the digital co-pilot for mission control. In the office, AI will become the indispensable digital co-pilot for project teams. Its primary role will be to automate administrative burdens—summarizing daily reports, analyzing the sentiment of RFIs, and flagging high-risk items in submittals. This is what enables the "mission control" concept - it frees up project managers from reactive firefighting and empowers them with the data to make proactive, strategic decisions."

"In 2026 AEC companies will use AI in two significant ways. First, AI will analyze design and construction data to identify potential challenges and reveal opportunities for optimization. By evaluating historical project data, material costs, and supply chain information, AI will facilitate risk mitigation. It can also be used to improve quality methods by analyzing process and audit data, comparing digital plans against actual delivery, and help to automate inspection. Second, AI and particularly through model context protocol (MCP) will be used to build more robust digital workflows by connecting capabilities and automating manual and error prone tasks.

The primary benefit will be providing data translation between heterogeneous design and collaboration tools. AI will enable building design tools to explore wider set of building solutions and empower optioneering for building components. Additionally, MCP will connect design tools supply chain data to provide access to material costs, availability and sustainability information improving early design decisions and accelerating workflows. "

"In Canada, the construction industry is entering a phase where technological, geopolitical, and security considerations are becoming structural. Growing reliance on foreign digital platforms, combined with the current global political climate, is accelerating interest in digital sovereignty, data security, and technological independence, influencing how digital infrastructures and information flows are governed across projects. At the same time, increased investment in defense, critical infrastructure, and resilience is raising expectations around data protection, traceability, and risk management. In this context, data has become a strategic asset. Architects, aFrom a Canadian perspective, artificial intelligence will be firmly embedded in the construction industry by 2026 as a professional enabler, not a substitute for expertise. Within Canada’s regulatory and risk-conscious environment, AI adoption will focus on automating repetitive and low-value tasks such as document production, baseline compliance checks, data analysis, and reporting.

This shift will allow architects and project teams to concentrate on higher-value activities—professional judgment, advisory services, strategic thinking, and complex problem-solving. AI will function as a co-pilot, improving efficiency and consistency while preserving human accountability. Used responsibly, AI should not weaken professional thinking but elevate the complexity and value of the challenges architects are able to address, reinforcing trust, ethics, and professional integrity."

"This is a big topic. AI will continue to inform virtually everything in construction in the coming years, whether it’s preconstruction, bidding, design, or construction operations. That “digital footprint” of past construction projects with labor, subcontractors, materials, and supplies to costs can and will be informing future projects that would be similar in nature to those past projects. This will result in huge time savings and cost efficiency gains with labor, material and supplies procurement, and project management."

"AI is moving at a rapid pace across all sectors and potentially the most disruptive technology that we will experience in our lifetime. I see opportunity where the hype moves into practical use for instance with estimating, scheduling, and proactive risk management for construction. We know that AI workloads will continue to fuel the data center demand and there will be a significant intersection between these projects harnessing AI to drive planning, design, installation, commissioning, and proactive operation management."

"AI is rapidly moving from concept to co-worker on construction sites, and 2026 is shaping up to be a turning point. Building on recent momentum, firms are deploying AI to monitor safety and progress in real time, flagging hazards before they become incidents. Machine learning and generative AI are streamlining repetitive tasks like document processing and clash detection, freeing teams to focus on higher-value work. These advances not only ease labor shortages but also boost speed, quality, and decision-making.

At the same time, trust and transparency are becoming just as critical as innovation. While most construction leaders believe AI will enhance the industry, concerns around data privacy and ethical use are growing. Companies are responding with governance frameworks and tools, such as AI Transparency Cards, that provide clear disclosures on how AI features operate and how data is protected. Solutions that keep sensitive project information within secure ecosystems are gaining traction, ensuring confidence as adoption accelerates. 2026 will be the year AI proves its value not only through efficiency and safety gains but also through responsible, trustworthy integration into everyday workflows."

"In 2026, AI in construction will move from "nice-to-have" to normal operational practice - driving smarter planning, automated progress updates, and more accurate forecasting through digital twins. Routine administrative tasks such as reports, document handling, and digital forms will be increasingly automated. On-site team will benefit from AI-powered Assistant or AI agent with instant access to updated information. Ultimately, AI will not replace people but will supercharge the project team by simplifying workflows, reducing human errors, and transforming them into data-augmented decision makers.

"So far, most of the buzz has been about AI in the field with progress tracking, image recognition, safety, and so on. By the end of 2026, I expect the more important story to be AI showing up in the least forgiving parts of the business: finance, compliance, and controls. Those workflows don’t have room for hallucinations, so you’ll see AI paired with structured rules and approval paths to handle invoices, pay apps, change orders, lien waivers, and vendor compliance, with humans focused on the edge cases and commercial judgment instead of re-keying data.

B2B SaaS usually follows the patterns in the consumer world: once people get used to an assistant living inside the tools they use every day, they expect the same thing at work. I expect construction software to follow that arc: starting with simple summarization and search, then quickly moving to AI that can propose coding, spot financial risk, and help orchestrate multi-step workflows across field and back-office systems—quietly raising the bar on accuracy and speed without trying to replace the people running the projects. I think 2026 is the year when that becomes not only possible but widely adopted across the industry."

"In 2026, AI will shift from a separate layer of innovation to a true partner in daily decision making. AI will help teams understand the immediate impact of design and planning choices by assessing constructability, cost, energy performance, and scheduling simultaneously. This will sharpen coordination, align intent with execution, and give teams the confidence to explore more options with less rework. AI agents built specifically for the AEC industry will monitor project conditions, flag risks early, recommend alternatives, and automate the repetitive tasks that slow teams down today. These agents will be supported by computer vision and automated progress tracking that give teams a clearer picture of what is happening in the field.

AI will also begin turning years of project knowledge into insights that anyone can use, narrowing the gap between veteran expertise and rising talent. The organizations that gain the most will be those that adopt AI with intent and build a culture grounded in curiosity, transparency, and steady improvement. For leaders who pair smart tools with strong collaboration, 2026 will mark a turning point where this innovative mindset produces real results."

In 2026, I believe one of the most prominent areas of advancement for AI in the construction industry will be safety and health. Every year, countless accidents occur across global industrial sites, and construction teams have long relied on safety guidelines, inspection procedures, and monitoring systems to prevent these incidents. However, there are clear limitations to relying solely on human oversight to monitor and control every potential hazard in real time.

Against this backdrop, AI-powered vision-based safety systems have been rapidly expanding. By analyzing video feeds from CCTV, drones, and wearable devices in real time, AI can detect potential risks—such as fall hazards, heavy equipment proximity, missing PPE, or unauthorized access to dangerous zones—and immediately alert site managers. This technology is quickly becoming a new standard for proactive safety management.

In addition, AI-driven predictive safety technologies leveraging BIM data are advancing rapidly. By analyzing 4D BIM models and construction schedules, AI can identify potential process conflicts, equipment path interference, and worker exposure risks before they occur, shifting safety management from reactive measures to true prevention."

"The year 2026 is expected to provide further insights into the practical applications of AI in daily operations. Significant advancements are anticipated, particularly with the establishment of additional industry standards. These improvements will likely enable AI to automate a greater proportion of manual tasks within the AECO sector, especially regarding BIM model development, Scan-to-BIM processes, clash detection, and building site monitoring. Furthermore, AI holds the potential to enhance both the quality and the maturity of As-built documentation. With appropriate guidance, AI may serve as a valuable tool for improving design practices and contributing to the development of more sustainable buildings for the future."

What does the future hold for the construction sector in 2026? No one has a crystal ball that can predict what will happen with 100% certainty. But we can make intelligent forecasts based on industry trends and expert insights.

And so far, the data is clear. Autodesk’s State of Design & Make: Construction Spotlight report shows that construction leaders are grappling with many of the same pressures hitting other industries. Economic uncertainty, labor shortages, rising costs, and supply chain delays are just some of the headwinds we’re all facing.

But it’s not all doom and gloom, especially for firms that have invested in digital maturity and more connected ways of working. The research shows that 62% of leaders still feel positive about the future of the construction industry overall.

This finding tells us that companies that embrace technology, data, and process improvements feel better equipped to navigate uncertainty and adapt to what’s coming next.

So what exactly *is* coming next?

To better understand what that future could look like, we caught up with 25+ construction experts to hear their perspectives on what’s ahead for the industry.

Check out what they have to say.

"In 2026, the construction industry is expected to see a significant increase in modular construction and prefabrication solutions. The design and engineering phase will need to be more precise and clash-free, utilizing highly accurate 3D models. This will allow construction teams to focus on execution and deliver projects faster while managing increasingly complex designs.

We will also see a growing number of projects focused on storing both virtual and physical assets—such as data centers for digital information and facilities dedicated to preserving human heritage, including museums and similar institutions.

The adoption of IoT technologies will accelerate, making smart buildings the new standard alongside digital twin implementation. Sensors embedded throughout facilities will monitor energy consumption, structural health, and environmental conditions in real time. This data-driven approach will improve efficiency, reduce maintenance costs, and enhance occupant comfort and safety, while supporting sustainability goals through optimized resource usage."

"In 2026, construction will continue moving toward a stronger focus on project outcomes, communication, and operational excellence. Owners in the public and private sectors are expecting contractors to bring more clarity, more professionalism, and more consistency to every phase of a project.

I also predict a significant shift toward upgrading and modernizing existing facilities. Many organizations are choosing to renovate and improve what they already have instead of pursuing large new developments. These types of projects often take place in active environments with complex logistics and multiple stakeholders, so fundamentals like planning, documentation, schedule management, and transparent communication will be more important than ever."

Steven Bloomer

GHD

"I believe that during 2026 we’ll see a major shift in how construction projects are designed, managed, and delivered. Safety on site will continue to improve as systems get better at spotting risks early and helping teams respond before an incident occurs. The focus will be on prevention rather than reaction. I see design tools will finally move beyond the traditional point-and-click approach. With AI working quietly in the background, we’ll be able to describe what we want, set the intent, and let the tools build out the detail, check requirements, and handle the repetitive tasks for us. The value won’t be AI itself, but the time it frees up.

I also believe that project information will be easier to find than ever before. Instead of digging through folders, file structures, or old emails, we’ll be able to pull up the exact drawing, decision, or piece of data we need in seconds. The time we currently lose searching for information will drop dramatically."

"Digital transformation will remain a key trend in the construction industry in 2026, with organizations continuing to invest in automation and advanced technologies to improve asset planning, delivery, and operation. Additionally, best practices emerging from sectors such as healthcare and datacenter are expected to influence the broader industry, promoting more integrated workflows and automated quality control. This evolution reflects a growing commitment to leveraging technology and lean processes for improved project delivery.

In response to economic uncertainties and workforce shifts, companies will place greater emphasis on data analytics to enhance risk mitigation and support informed decision-making. Owners will play a more active role in driving the adoption of digital solutions such as Common Data Environments (CDE), fostering collaboration among stakeholders, and enabling more connected construction practices."

"By the end of 2026, the construction industry will make a shift toward connected, data-driven project delivery. Successful organizations are already moving away from fragmented systems and adopting unified platforms where models, schedules, cost data, quality workflows, and field execution operate together. This level of connectivity will become the new baseline for high-performing teams.

Schedule certainty will rise to the forefront. With advancements in site capture, progress analytics, and integrated scheduling tools, project teams will rely on objective data to understand performance and forecast outcomes. Owners will increasingly expect transparent schedule health metrics, updated continuously, not monthly."

"Construction in 2026 will be defined by divergent market conditions and accelerating technology adoption. Data centers and specialized infrastructure—driven by hyperscalers—will command focused investment and aggressive deployment of AI and automation tooling. Traditional commercial sectors will experience more subdued activity, with potential pickup towards the end of 2026. Persistent labor shortages will make digital transformation and automation essential for survival, not optional. Companies that invest strategically in these areas, secure key partnerships, and adapt to rising material costs will thrive, while those clinging to legacy approaches will struggle."

"Looking ahead, the construction industry is set to be transformed by several emerging trends in 2026. There will continue to be an increasing shift towards earlier and more integrated decision-making driven by the need to build faster, safer, and with greater certainty, while reducing rework and material loss. Teams will seek tools that make processes more efficient and help to eliminate ambiguity. There will also be a surge in extended reality enabled planning, where teams validate logistics, safety and project phasing before breaking ground.

Firms will continue to want more confidence in projects. The tools that thrive will be those that help people step inside of their decisions—together."

"I believe the construction industry will continue to adopt technology at a greater degree in 2026 as it has for the last few years now. A big way I think this will manifest is through greater adoption of robotics and automation in construction. As retirements continue to vastly outpace the new blood entering the industry, increased use and capacity of robotics will be required to keep up with the demand for construction."

"I’ve been fortunate to sit in hundreds of customer conversations this year, and it’s left me more optimistic than ever about where technology adoption is headed. In 2026, construction won’t be resisting change — it will be leaning into it. Automation will start chipping away at long-standing inefficiencies, and platforms that connect design, construction, and operations will unlock stronger collaboration across the entire project lifecycle.

This isn’t just about doing things differently; it’s about doing them better, faster, and with less risk. We’ll finally start turning lessons learned from past projects into tangible improvements on future ones. Innovation has been accelerating every year, and 2026 will be the moment our industry truly capitalizes on that momentum and embraces meaningful, positive change."

"From a mission critical perspective, the biggest force shaping 2026 will be the continued surge in power demand. Data centers and battery plants are being built at a pace the industry has never experienced, and the megawatt requirements for each new campus keep climbing. This creates two major impacts. First, long lead times on critical equipment and materials will remain one of the biggest risks for project delivery, simply because so many of these mega jobs are being built simultaneously across the US. Second, the scale of electrical infrastructure needed to support this growth will push both engineering and construction teams to think differently about prefabrication, coordination, and speed to market. The power race is not slowing down, and the industry will be adapting in real time."

Emmanuel Graves

Autodesk

"In 2026, Digital Project Delivery (DPD) will continue to progress from an innovation strategy to a contractually expected standard across the construction industry. This shift will be most prominent on projects requiring regulatory approval. Owners, developers, and governing authorities are increasingly requiring projects to operate within a digital, model-based, data-driven framework that connects design, construction, and operations through a Common Data Environment (CDE).

What initially began as a push for collaboration and productivity is now evolving into a standard of care—reducing contractual risk, improving data reliability, and establishing clearer expectations for how projects are executed. Legacy delivery methods built on fragmented data, manual handoffs, and siloed teams are no longer sustainable as project complexity and regulatory demands increase."

"By 2026, I predict construction teams will actively integrate IoT technologies on site to improve safety, reduce risk, and capture real-time project insights. Sensors, wearables, and connected equipment will shift from optional add-ons to essential policy and contractual requirements. I also expect clients to increasingly mandate compliance with international standards such as ISO 19650, 7817, 16739 and others to ensure consistent, high-quality information throughout the asset lifecycle. Together, these changes will drive a more connected, data-driven, and accountable construction industry."

"As the global construction industry enters 2026, firms are navigating a complex mix of resilience and constraint. Public investment, digital maturity requirements, and persistent workforce pressures are reshaping how projects are planned, procured, and delivered. The following themes highlight the structural forces most influencing outcomes across major markets.

Infrastructure continues to outperform the buildings sector, driven by sustained government-backed investment in transport, energy, and utilities, which is helping to stabilise civil construction despite broader economic softness. At the same time, labour and skills shortages are intensifying across major markets, pushing up labour costs, extending project schedules, and accelerating reliance on automation and modular construction methods.

Owners are also tightening expectations around digital delivery, with ISO 19650 compliance, structured data, and demonstrable common data environment (CDE) usage increasingly embedded in procurement requirements across the UK, Europe, the Middle East, and APAC. Despite these rising digital standards, hybrid delivery models remain the reality in 2026, as most contractors continue to rely on DWGs, PDFs, spreadsheets, and partially modelled data due to inconsistent and variable upstream design information—less a matter of preference than a practical response to input quality. Compounding these challenges, supply chain volatility persists, with material cost fluctuations, import delays, and geopolitical instability prompting firms to embed supply risk modelling more deeply into project planning and delivery strategies."

"The industry is moving from a traditional, fragmented model to one that is more integrated using digitalization, prefabrication, and data-driven methods, where the right expertise is integrated into the project delivery process at the right time. Some things stand out, including acceleration of mega projects in the mission-critical, life sciences, and healthcare sectors; the industrialization of building with modular and prefabricated construction becoming the norm; and the ongoing skilled labor shortage remaining the most critical long-term challenge, compounded by an aging workforce."

"In 2026, the construction industry will continue accelerating its shift toward digital-first and data-driven project delivery. We’ll see a major rise in modular and prefabricated construction as owners push for faster schedules, stronger cost certainty, and reduced environmental impact. Digital twins will become more mainstream—linking BIM with real-time schedule, cost, and field progress data for better risk mitigation and transparency.

With skilled labor shortages and material cost volatility still present, contractors will adopt smarter planning and leaner workflows supported by technology like drones, 3D scanning, robotics, and AI-based project controls. Ultimately, technology will evolve from a support function into the operational backbone of construction, driving productivity, quality, and collaboration across all phases of a project."

"My core prediction for 2026 is the transformation of the job site into a "smart jobsite." To power this, AI needs better data, and the industry will finally invest heavily in retrieving that data directly from the builders themselves. We'll see more physical tech in the field—like dedicated stations for interaction, QR codes as simple entry points to digital tools, and large-screen displays that provide thoughtful, actionable guidance for teams instead of just lagging metrics. This turns the construction office into a "mission control center," using real-time field data to guide the project, much like controlling a rocket launch."

"In 2026, AEC companies will respond to industry pressures on cost, waste, and efficiency by embracing productization for building components. Many AEC companies have recognized that traditional methods prevent them from scaling their business and are exploring new means to build more effectively, reduce waste, and serve more customers, resulting in increased margins. Repeatability is the core principle required to change the AEC industry.

This pattern is used to define a component as a building product. Productization allows subcontractors, fabricators, and building product suppliers to define the components they make as configurable products that an architect or general contractor can design with. Designing with these building products ensure geometric accuracy during design, that any given component will always be manufacturable, and reduces risk across the entire project lifecycle."

"In Canada, the construction industry is entering a phase where technological, geopolitical, and security considerations are becoming structural. Growing reliance on foreign digital platforms, combined with the current global political climate, is accelerating interest in digital sovereignty, data security, and technological independence, influencing how digital infrastructures and information flows are governed across projects. At the same time, increased investment in defense, critical infrastructure, and resilience is raising expectations around data protection, traceability, and risk management. In this context, data has become a strategic asset. Architects, as major producers of building data through BIM models and technical documentation, are increasingly positioned as responsible stewards of that data."

"I think there’s evidence that increased AI, machine learning and robotics will continue to permeate the industry, both in terms of preconstruction, bidding, and estimating, through operations and finance. Construction and infrastructure rehabilitation will continue, primarily funded by the federal government (see airports, bridges, train stations, etc) but commercial construction will see mild growth as well. However, margins on commercial construction projects will continue to be thin, as pressures on labor and materials continues to persist."

"In 2026, the APAC construction industry is expected to experience selective and uneven growth, with strong momentum in sectors such as infrastructure, healthcare, advanced manufacturing, and data centers, while traditional office and retail markets remain relatively subdued. Data centers in particular will play a major role in driving recovery, as hyperscale and AI-ready developments accelerate across key hubs including Singapore, Tokyo, Mumbai, and Sydney, fueled by cloud adoption, AI demand, and data sovereignty requirements.

At the same time, the industry will continue to face persistent challenges such as skilled labor shortages, power constraints, and cost escalation, though earlier contractor engagement is expected to unlock greater benefits from modular construction and Design for Manufacture and Assembly (DfMA). In Australia, regulatory pressure will also increase, with climate-related financial disclosures becoming mandatory from 1 July 2026 for medium-sized entities across all sectors, requiring construction businesses to produce audited sustainability reports aligned with AASB standards and comprehensive Scope 1–3 emissions reporting."

"Like a skyscraper rising from steel and concrete, the construction industry in 2026 will build its future on technology. Automation and AI are no longer buzzwords; they’re becoming the backbone of modern job sites. Intelligent machinery and robotics are taking over repetitive tasks, while predictive analytics sharpen planning and execution. Digital twins, BIM, and immersive AR/VR tools are transforming collaboration, letting teams simulate, monitor, and troubleshoot projects in real time. Modular and prefabricated methods are speeding up timelines with factory-level precision, tackling labor shortages head-on. At the core of this shift is data: unified platforms are turning raw project information into actionable insights, reducing costly rework and boosting efficiency.

But tech isn’t the only game-changer; sustainability and talent are shaping the next chapter. Firms face mounting pressure to reduce their carbon footprints, adopt circular building models, and comply with climate disclosure rules. Low-carbon materials, recycling, and green design are becoming standard practice. Meanwhile, workforce investment is critical: companies are doubling down on upskilling programs to keep pace with innovation and close persistent labor gaps."

"The construction industry in 2026 is likely to see a major shift towards smarter, more automated and integrated project delivery. AI-driven planning, real-time digital twins and automated progress verification will accelerate how projects are coordinated and monitored, reducing delays and reworks. Prefabrication and industrialized construction will grow as companies push for faster, more controlled production environment, supported by robotics, automated quality checks and digital tracking. On-site, wearable tech or beacon tags, AR/VR tools and digital work instructions will improve safety, communication and precision. Procurement and contracts will become more transparent and data-driven, with analytics predicting risks earlier.

Overall, the industry will move toward a more connected ecosystem where digital delivery and automation work together to make project faster, safer, efficient and far more collaborative than today."

"In 2026, I think the big split in the industry will be between builders who treat data as core infrastructure and those who still treat it as paperwork. More contractors will narrow down to a few core systems for field operations and finance, then wire them together so quantities, changes, and costs flow automatically instead of being copied between emails, PDFs, and spreadsheets. That shift turns WIP and margin reviews from a backward-looking monthly ritual into something much closer to a live pulse on each project.

At the same time, “industrialized construction” will extend past the jobsite. The leaders will reuse workflows, data models, and playbooks across projects instead of reinventing them each time. They’ll still pour concrete and hang duct like everyone else; but behind the scenes, they’ll run much more repeatable, data-driven businesses that scale more efficiently."

"In 2026, the industry will take major steps toward fully connected project data. Integrated digital ecosystems will allow for design intent, field inputs, and cost information to interact in near real time, giving teams clearer visibility and reducing surprises. This shift will support earlier and more confident decision-making and help owners embrace delivery models that reward collaboration from the start.

The importance of sustainability will accelerate as early energy modeling becomes faster, easier to use, and far more reliable. At the same time, growing power demands from energy intensive technologies like AI are making power efficiency an even more critical priority for society than ever before. Better predictive tools will help teams evaluate performance choices with real confidence, guided by first principles thinking that links planning, design, construction, and operations in a more intentional way."

"The dominant themes for the construction industry in 2026 will be AI and robotics. For years, the industry has struggled with structural challenges such as labor dependency, rising wage costs, time constraints, and persistent safety risks. To overcome these limitations, the adoption of AI-driven tools and robotic systems has steadily accelerated across global project sites.

In 2025, we saw experimental but meaningful applications of robot-assisted construction, autonomous equipment, and AI-based inspection automation on various job sites. Looking ahead to 2026, these technologies are expected to expand beyond pilot programs and become integral to project delivery—optimizing repetitive tasks, reducing high-risk manual work, and enabling AI to support decision-making in scheduling, quality control, and safety prediction."

"2026 is poised to mark a significant transformation in the development practices of the construction industry. My professional experience in the digitally mature BIM sector in Scandinavia has shown me that distinctions between countries and regions within the international AECO industry are becoming less pronounced. The adoption of international standards will facilitate greater automation and AI integration, while knowledge sharing among industry experts will promote modular design and the use of BIM models for prefabrication and subsequent operational phases.

I anticipate a strong emphasis on sustainability (especially in European context) and maintenance considerations in future designs, leading to improved built environments."

We've been having a LOT of conversations about AI, most of which center on broad strokes and high-level insights. Think: the potential of AI, its legal implications, and why teams should adopt it.

This episode of Digital Builder is a little different. I'm joined by Dr. Sarah Buchner, founder and CEO of Trunk Tools, a platform that automates construction workflows through AI.

Rather than giving 35,000-foot takes on artificial intelligence, Sarah gets into the trenches. We talked about the messy reality of AI adoption, the necessity of tough love when teams resist change, and how to deal with the fears that hold teams back.

We discuss:

Being an AI company itself, you'd think that Trunk Tools wouldn't have any trouble getting the team on board with AI. But according to Sarah, she herself faced challenges in encouraging broad adoption across the business.

"The process wasn't elegant. We are fully AI native, we produce AI, and we still had struggles adopting AI in every department."

Sarah says the process involved a lot of "top-down pushing" across departments, with leaders promoting the use of new AI tools and encouraging teams to rethink workflows and objectives.

She continues, "Change is hard for humans in general. And so we need to create an environment where change is incentivized by either a stick or a carrot. I used a carrot first, then I used a stick."

Sarah breaks it down simply: construction has three groups that matter for AI adoption.

First, you have the people in the field who actually use the tools. Then there's the support teams like IT and legal, and finally, the executives who set direction.

According to Sarah, "the only times I've seen a successful AI adoption… is when at least the C-suite and the field were aligned."

Support functions matter, but they shouldn't be blockers. If legal or IT keeps saying no, Sarah's advice is to get them help. "Your lawyer that does the normal GC contract might not be the best lawyer to look at an AI company," she says. The same goes for IT. If they're not equipped to evaluate AI, bring in outside expertise.

But even with the proper support, nothing moves if the field doesn't see value. "No AI will get adopted if the field doesn't see value and if there's no top-down pressure." In other words, it can't be a pure bottom-up effort. The C-suite has to signal that AI matters, back it with real support, and be willing to change how the business works.

Sarah also pushes back on the idea that construction has a "technology adoption problem." The real issue, she says, is that many tools simply aren't adoptable. "UIs from the nineties and workflows with manual data input are just dead." If you give the field something that actually removes pain, they'll use it. But without leadership modeling the change and clearing the roadblocks, even the best tools won't stick.

When discussing AI's impact, Sarah draws a clear line between blue-collar and white-collar work.

She doesn't see AI changing hands-on field tasks anytime soon. It might help in small ways, like pulling up information with tools like Trunk Text, but the physical craft itself isn't going anywhere. As she puts it, "I'm actually very excited that the future means that blue collar workers will be even more uplifted… because that's not automatable."

The AI story is different on the white-collar side. Sarah points to research showing that "about 80 percent of white collar workflows in construction can be automated with the technology that's out there today." It's a tough reality for some teams, but it's also where the biggest ROI sits. Repetitive, clearly defined workflows—especially those that mix rules with pattern recognition—are the first to benefit.

Meeting minutes, search and retrieval, scheduling, and other administrative or coordination-heavy tasks follow the same pattern. Plenty of tools already exist to optimize schedule logic and clean up routine documentation.

She continues, "We see a lot of smaller workflows that are really done end to end by AI, which is really exciting."

That "end-to-end" implementation is something that Sarah is really bullish about, not just because of the efficiency gains, but also because it'll help with AI adoption.

"We are focusing more and more on end-to-end autonomous agents. What that means is there is a trigger, and then the agent actually does it without any human involvement. Once you reach that level, we don't need the behavioral change to happen, which has always been the problem in construction tech."

When getting started with AI, Sarah's first piece of advice is simple: start at home. "It's less scary, there's less risk involved," and it helps people loosen up creatively before bringing AI into their job. She tells folks to play with it in ways that feel fun and low-stakes. Write a personalized bedtime story for your kids. Ask it for a new recipe. Plan your trip to Paris. Just "start talking to it" the way you'd talk to an expert in whatever you're trying to figure out.

Once people feel comfortable, then bring it into work. At Trunk Tools, Sarah actually requires her executives to spend two hours a week talking to an AI about the problems they're wrestling with. She wants them to treat it the same way they'd speak to a McKinsey consultant. And the tools are good enough now that they don't just answer a question. They suggest next steps, help you reason through decisions, and push your thinking forward.

For Sarah, the hardest part isn't the tech. It's getting people over the initial fear. Once they do, "you open up a whole world of possibilities."

Sarah sees AI as an opportunity to fix the problems people have been frustrated with for decades. It starts small. AI wipes out boring, bureaucratic tasks that nobody in the field wants to touch.

"I hated that part of my job… where I had to fill out a daily log," she says. "Nobody has to fill out a daily log anymore. AI can do this for you." Those little wins add up fast.

But the bigger impact is on rework. Roughly 10 percent of construction costs come from doing things twice. Sarah's team has shown in R&D that "about 80 percent of this you can actually figure out with AI before it happens." They're catching RFIs before they hit the site. At industry scale, that could mean a trillion dollars saved and a massive reduction in carbon emissions.

To get there, leadership has to lean in early. One GC CEO told her he wasn't fixated on whether Trunk Tools was the exact right tool long-term. What mattered was getting his people to "start thinking about AI," because that mindset shift will matter more than switching tools later.

That's the kind of behavior Sarah wants to see across the industry. And it's why she's genuinely excited about where construction is headed.

Digital Builder is hosted by me, Eric Thomas. Remember, new episodes of Digital Builder go live every week. Listen to the Digital Builder Podcast on:

or wherever you listen to podcasts.

Bid bonds aren't the flashiest part of construction, but they can make or break your ability to win work. If you're bidding on public projects or any job where the owner needs assurance that you can deliver, a bid bond is your first line of credibility.

This guide covers the ins and outs of bid bonds, including what they are, why owners require them, and how they work.

Table of contents:

Bid bonds in construction are a type of surety bond that serves as a guarantee to the project owner (the obligee) that a contractor (the principal) who submits a bid will:

Bid bonds protect the owner financially in case the contractor wins the bid but backs out or can't provide the required bonds.

Requiring bid bonds is in the best interest of the construction project owners and contractors. Here's why they matter.

Bid bonds give owners confidence that the contractor they select can actually deliver on their bid. When a contractor includes a bid bond, it signals that a surety has already reviewed their financials and believes they can take on the job.

It also prevents lowball bids from contractors who hope to renegotiate later.

Additionally, a bid bond protects owners from the cost and delays that come from a contractor backing out. If the selected bidder fails to sign the contract or provide required bonds, the bid bond can be used to offset the owner’s resulting costs. With a bid bond in place, owners reduce risk and keep the project moving forward.

Having a bid bond shows that a surety has vetted the contractor and can take on the work without issue. This builds credibility with owners who want partners they can count on. A solid bid bond also helps contractors stand out in a crowded field, especially when competing for larger or more complex jobs. When you show up prequalified, it sends a message that you take the project seriously and have the financial stability to follow through.

Public agencies often require bid bonds to safeguard public funds. Cities, states, and federal agencies want to make sure that contractors bidding on taxpayer-funded work are financially sound.