Learn how discrete event simulation improves lean manufacturing by modeling real operations and testing new ideas before changes occur on the shop floor.

Manufacturers operate under constant pressure to extract greater throughput from the same assets and uphold demanding delivery schedules. Lean manufacturing creates discipline by cutting waste, balancing station workloads, and syncing material flow to demand. However, the real challenge is foresight. Before changing layouts or schedules, teams must understand how tweaks to, staffing, or kanban sizing will impact the entire operation.

FlexSim: 3D Discrete Event Simulation Software

Easy-to-use 3D simulation modeling and analysis software with high-end capabilities. Predict and optimize production processes with realistic 3D visuals and data-driven scenarios.

Discrete event simulation (DES) addresses this problem by providing a virtual environment to model, test, and refine strategies before they are implemented on the factory floor. Read on to learn more about simulation-driven lean manufacturing and the Autodesk tools that bring its power to your fingertips.

Discrete event simulation for lean practices

Discrete event simulation represents a production system as a sequence of time-stamped state changes. Material arrivals, machine faults, setups, and task completions occur at specific instants, and each event updates queues and resource statuses. In a field as dynamic as manufacturing, DES enables teams to predict how proposed process changes will affect throughput, cycle time, and inventory. Unlike spreadsheets or physical trials, simulation incorporates randomness and lets engineers capture real-world conditions like demand fluctuations or equipment variability.

In a lean operation, discrete-event simulation offers teams a moving picture of how materials, parts, and people travel through the plant. By mirroring current and proposed workflows, engineers can spot waste as it occurs and trace its cause. For line balancing, the model surfaces real cycle-time variation rather than tidy averages, making it easier to redistribute tasks, adjust buffers, and smooth utilization so bottlenecks fade instead of shifting downstream.

Just-in-time planning follows the same principle: you can test replenishment intervals and supplier delivery windows, then read the impact on throughput and delivery performance before changing a single fixture on the floor.

An important advantage of simulation-driven lean initiatives is risk reduction. Physical implementation of lean projects can be costly and disruptive if results don’t meet expectations. Simulation provides a safe environment for “what if” experiments so that teams can refine strategies without interrupting production. This leads to better-informed decisions and smoother transitions from planning to execution.

Using Autodesk FlexSim to support lean manufacturing

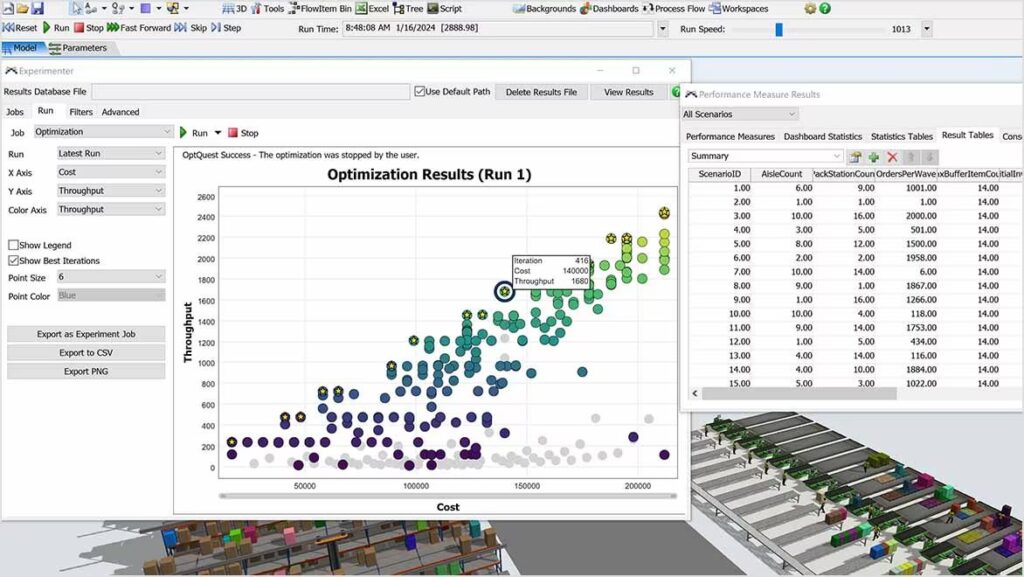

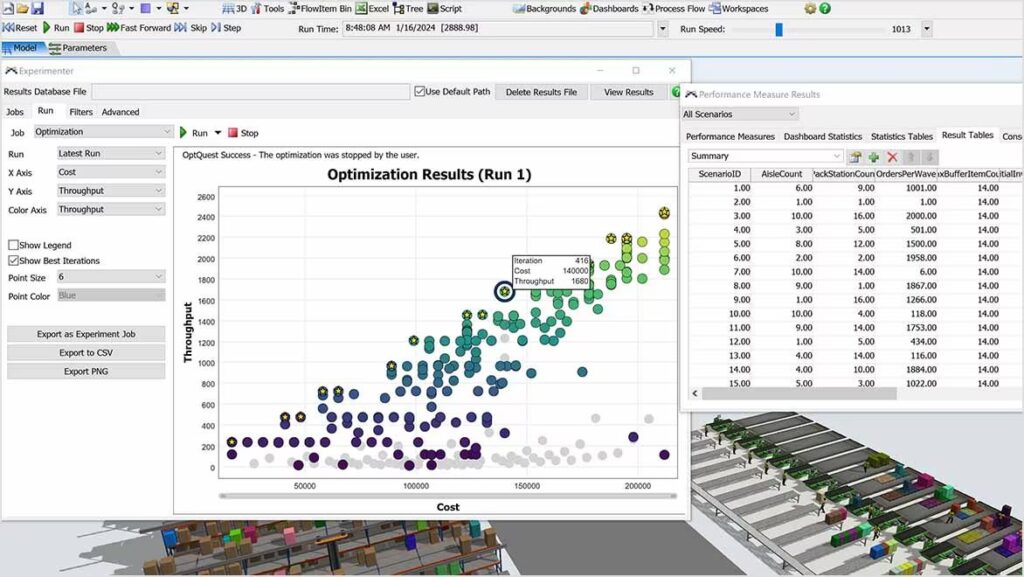

Autodesk FlexSim is a leading discrete event simulation platform designed for manufacturing environments. It combines ease of use with advanced capabilities so engineers and designers can construct detailed models that support lean manufacturing objectives. And, with an intuitive drag-and-drop interface and pre-built logic, FlexSim helps all teams quickly create accurate models without the extensive programming or technical backgrounds necessary.

For waste reduction, FlexSim unlocks data-driven analysis and visualization of the flow of materials, resources, and people. By running different scenarios, manufacturers can pinpoint inefficiencies such as excess transport routes or underutilized workstations. Meanwhile, line balancing is supported through detailed cycle time analysis, where FlexSim’s scenario manager can run optimization experiments that test different staffing levels or machine allocations to achieve smoother throughput. When applied to just-in-time production, FlexSim’s integration of real-time data and its ability to simulate scheduling changes help guarantee that inventory is minimized without risking stockouts or late deliveries.

Beyond supporting lean principles, FlexSim’s realistic 3D visuals and detailed process mapping make it easier to communicate proposed changes to stakeholders. By presenting complex ideas in an interactive model, teams can understand, evaluate, and make decisions with greater confidence.

Lean and mean

Lean manufacturing thrives on precision, but effective execution requires more than process maps and theoretical models. Discrete event simulation closes the gap between planning and execution with a way to test lean initiatives in a digital space before committing to real-world changes. With tools like Autodesk FlexSim, companies gain the ability to model complex systems and make evidence-based decisions that drive lasting improvements.