Discrete event simulation (DES) enables manufacturers to analyze, model, and optimize complex production systems without disrupting real-world operations. As the manufacturing ecosystem grows more dynamic—with variables like supply chain volatility, custom product demands, and automation—DES provides a virtual sandbox for experimentation, forecasting, and cost optimization.

Table of contents

- How discrete event simulation (DES) & modeling helps manufacturing make better decisions

- What is discrete event simulation (DES)?

- Why manufacturers rely on DES for decision-making?

- Discrete event simulation (DES) in the digital factory

- Key applications of discrete event simulation (DES) in manufacturing

- Benefits of discrete event simulation (DES)

- How discrete event simulation (DES) transforms complex decision-making

- Autodesk FlexSim: Bringing DES to life

- The future of discrete event simulation (DES)

- The competitive edge of simulation-driven manufacturing

How discrete event simulation (DES) & modeling helps manufacturing make better decisions

Manufacturers have numerous options to consider when trying to gain a competitive edge. These often include investing in new equipment, optimizing processes, or leveraging AI and digital transformation tools. However, the challenge becomes choosing the right combination of strategies.

Traditional methods like spreadsheets fall short due to the complexity of modern production systems, and physical studies are often impractical and costly. Manufacturers need a way to experiment and evaluate changes without disrupting production. Simulation allows for studying specific systems or entire operations, helping predict the impact of changes on production. Discrete event simulation (DES) is a proven modeling method that uses data to forecast the effects of changes in a manufacturing system. Let’s take a look at how DES works, its advantages, its applications, and how Autodesk FlexSim can help.

What is discrete event simulation (DES)?

Discrete event simulation (DES) models the sequence of events in a production system, tracking changes at precise time intervals. Each event—such as the start or end of a process, the arrival of materials, or an equipment breakdown—affects system performance. Unlike continuous simulations, DES focuses on discrete, measurable activities, making it ideal for analyzing operations like manufacturing, logistics, and service workflows.

DES translates these real-world systems into dynamic virtual environments. Using data inputs like cycle times, resource capacities, and process variability, engineers can run hundreds of “what-if” scenarios to understand how changes will impact output, efficiency, and cost.

Why manufacturers rely on DES for decision-making?

Modern factories face relentless complexity. From fluctuating supply availability to customization demands, predicting outcomes from multiple variables is nearly impossible without simulation. Discrete event simulation (DES) bridges that gap by helping teams:

- Evaluate potential process changes before implementation

- Detect bottlenecks that impact production flow

- Predict system behavior under various constraints

- Optimize layouts, staffing, and resource allocation

- Reduce production risks associated with new investments

DES is essentially the data backbone of the digital factory, enabling leaders to see how the system behaves holistically—something no static report or spreadsheet can replicate.

Discrete event simulation (DES) in the digital factory

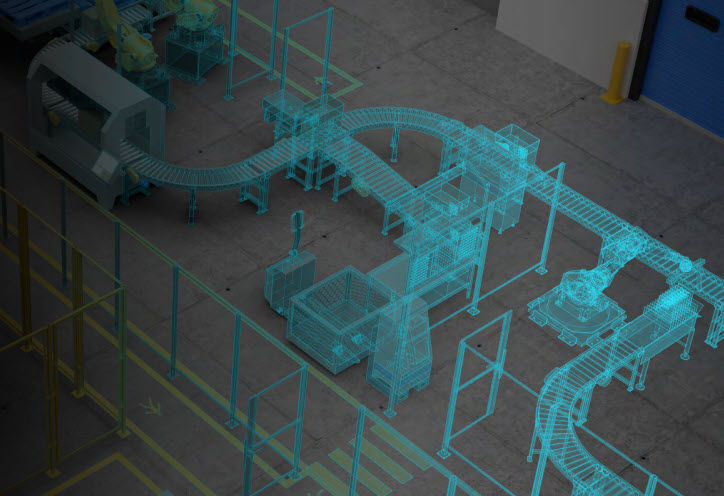

In digital manufacturing, where connected systems form the backbone of design, production, and maintenance, DES supports model-based decision making (MBDM). Integrated with digital twins and IoT data, it allows constant feedback between virtual models and real-world performance metrics.

Applications in the digital factory include:

- Factory design and layout planning: test numerous spatial configurations before building.

- Resource optimization: simulate equipment utilization and operator workloads.

- Scenario analysis: predict system behavior under changing demand conditions.

- Maintenance and scheduling: simulate machine downtime and optimize maintenance intervals.

By connecting with Autodesk solutions such as FlexSim, teams can visualize discrete event simulation (DES) outputs with photorealistic accuracy, helping stakeholders across departments understand potential outcomes before making high-stakes decisions.

Key applications of discrete event simulation (DES) in manufacturing

Factory layout and expansion

DES helps visualize and optimize factory layouts, ensuring efficient use of space, materials, and resources before construction. This results in faster commissioning and higher initial throughput.

Production line optimization

DES identifies bottlenecks in assembly lines, ideal batch sizes, and equipment utilization rates, allowing engineers to fine-tune scheduling parameters and reduce idle times.

Capacity planning

Manufacturers can simulate multiple demand scenarios to determine the optimum capacity needed to meet delivery targets with minimal overtime and resource waste.

Maintenance and reliability

By modeling breakdowns, repairs, and preventive maintenance schedules, DES supports predictive maintenance programs that minimize downtime and maximize output.

Supply chain simulation

DES allows end-to-end modeling of logistics and inventory movement. Manufacturers gain visibility into variability across suppliers, transport routes, and distribution nodes.

Benefits of discrete event simulation (DES)

- Reduced bottlenecks: Identify process bottlenecks and dependency conflicts before they occur in production.

- Improved resource utilization: Optimize labor, equipment, and material flow.

- Faster time-to-market: Test system changes virtually to accelerate deployment.

- Risk-free experimentation: Run simulations without interrupting ongoing operations.

- Cost savings: Prevent overinvestment in capacity by validating actual constraints.

- Enhanced collaboration: 3D visual models allow cross-department teams to align decisions through shared system visualizations.

How discrete event simulation (DES) transforms complex decision-making

Discrete event simulation’s greatest strength lies in its ability to reveal cause-and-effect relationships hidden within operational complexity. Whether assessing new automation investments or fine-tuning production sequencing, DES gives engineering and management teams hard data to make informed, confident choices.

Case examples include:

- A food and beverage manufacturer eliminated a 30% efficiency deficit after finding bottlenecks caused by packaging station delays.

- An automotive supplier used DES during plant expansion to increase throughput by 12% without purchasing additional machines.

- A pharmaceutical company avoided a $50 million investment after DES revealed that a perceived bottleneck was actually caused by upstream batching misalignment.

FlexSim: 3D Discrete Event Simulation Software

Easy-to-use 3D simulation modeling and analysis software with high-end capabilities. Predict and optimize production processes with realistic 3D visuals and data-driven scenarios.

Autodesk FlexSim: Bringing DES to life

Autodesk FlexSim simplifies the process of building and refining simulation models through its intuitive, drag-and-drop 3D interface. With logic elements, visualization tools, and built-in analytics, FlexSim empowers teams to:

- Build large-scale digital factory models without coding

- Validate system performance based on actual data

- Compare design iterations in minutes

- Generate analytics dashboards for KPI monitoring

FlexSim’s strength lies in its combination of visual storytelling and quantitative precision—bridging engineering detail with management clarity.

The future of discrete event simulation (DES)

As manufacturing systems grow more connected and autonomous, discrete event simulation (DES) is evolving beyond traditional modeling into real-time decision environments. Integration with AI and machine learning algorithms now allows simulations to self-adjust parameters, enabling continuous optimization.

Emerging trends include:

- Parallel DES (PDES) for modeling large-scale systems faster

- Integration with AI-driven predictive analytics

- DES-powered digital twins for real-time simulation of ongoing processes

- Cloud-native DES platforms enabling global, collaborative access

These innovations are transforming DES from a planning tool into a real-time operational intelligence system.

The competitive edge of simulation-driven manufacturing

Discrete event simulation gives manufacturers a structured, data-driven path to continuous improvement. By blending accuracy, flexibility, and visualization, DES empowers leaders to experiment boldly and make confident, financially sound decisions.