This article examines the importance of Flexible Manufacturing Systems (FMS) in navigating volatile markets. It explains how modular and reconfigurable setups help manufacturers pivot production and manage supply disruptions. Learn how Autodesk solutions, like Inventor and Fusion, facilitate agility through automated asset modeling, process simulation, and cloud collaboration.

In modern manufacturing, volatility is the norm. Market demands can change overnight and supply chains are constantly disrupted. In such a volatile landscape, the traditional model of static, high-volume production lines often becomes a liability. As such, manufacturers now need to prioritize adaptability over pure speed, and Flexible Manufacturing Systems (FMS) offers a promising path forward.

The need for modular manufacturing

A flexible manufacturing system is a computer-controlled production setup designed explicitly to adapt to changing variables such as product specifications, batch sizes, or production sequences. In contrast to rigid transfer lines, an FMS relies on three components:

- A centralized computer for control

- Work machines that manipulate materials

- Automated systems for handling parts

This architecture supports flexibility both at the machine and routing level. Machine flexibility permits a manufacturer to produce the same product using different machines. If one unit requires maintenance or demand surges, operators shift production to another station with minimal impact on quality. Routing flexibility, on the other hand, allows teams to reorder the manufacturing sequence to keep production moving even if a specific process step is disrupted.

Among the various configurations available, the modular FMS stands out as the most adaptable. This approach combines elements from other system types to create workstation modules that engineers configure, modify, and upgrade. By treating the factory floor as a collection of interchangeable blocks rather than a monolith, manufacturers can more radically adapt production lines using existing equipment. The result creates a production environment that supports rapid prototyping and keeps costs low by maintaining production with fewer resources. This modularity is invaluable for high-performance industries like aerospace and automotive that need to guarantee accuracy while working with complex geometries.

While the benefits are clear, building these systems requires overcoming hurdles. For example, the initial equipment investment and the workforce skills gap can be daunting at the onset. However, once operational, these systems provide a safeguard against volatility. They allow facilities to pivot quickly to new designs or self-produce parts that might otherwise remain stuck in a delayed supply chain. In this way, organizations can absorb shocks and maintain throughput to effectively insulate the business from the unpredictability of the global market.

Engineering agility with Autodesk Fusion and Inventor

Autodesk supports the development and management of these complex systems through the combined power of Inventor and Fusion.

Inventor facilitates the detailed design of the factory floor by enabling engineers to model factory assets and layouts at an industry-leading scale. For manufacturers building modular systems, Inventor’s iLogic technology allows teams to use no-code programming to automate configurable models such as jigs and fixtures. A more automated approach, iLogic reduces repetitive modeling tasks and helps engineering teams quickly generate new tooling designs when production needs change.

Fusion complements these capabilities by connecting the data and workflows that drive the manufacturing process. As a cloud-based platform, Fusion unifies CAD, CAM, and CA so that distributed teams can simultaneously collaborate on product design and manufacturing processes. For example, Toyota used generative design in Fusion to design lighter, safer seat frames, experimenting with fabrication methods that combine mass production with additive manufacturing.

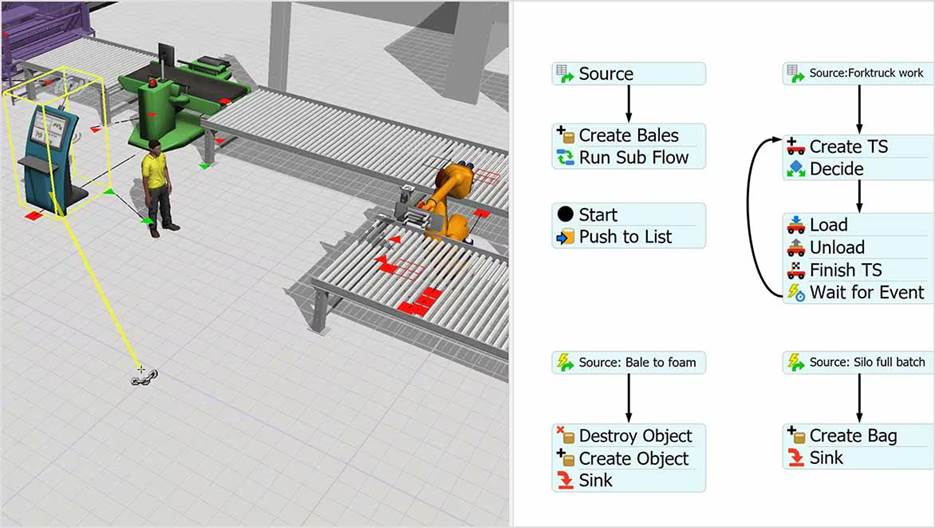

Autodesk has also integrated FlexSim with Inventor and Fusion Operations to let planners simulate production scenarios using real-time telemetry. This connection enables manufacturers to validate layout changes and optimize workflows digitally before physically moving any heavy machinery. As a result, teams reduce the risk associated with reconfiguring a line.

The construction and operation phases also benefit. Inventor can integrate directly with the Autodesk Construction Cloud to help factory operators detect clashes between manufacturing equipment and the building structure. Additionally, Autodesk Tandem creates a collaborative environment where stakeholders throughout planning and operations view a shared digital twin.

A hedge against volatility

As volatility becomes the manufacturing norm, more and more organizations will continue to embrace FMS. By investing in modular systems and leveraging advanced design software, manufacturers can build facilities that respond fluidly to the unpredictability of modern markets. By centralizing data and making it more visible, Autodesk is empowering manufacturers to build more resilient and stable factories.