Learn how connecting Autodesk Factory Design Utilities (FDU) with FlexSim enables true end‑to‑end factory simulation, improving throughput, reducing risk, and optimizing layout and operations.

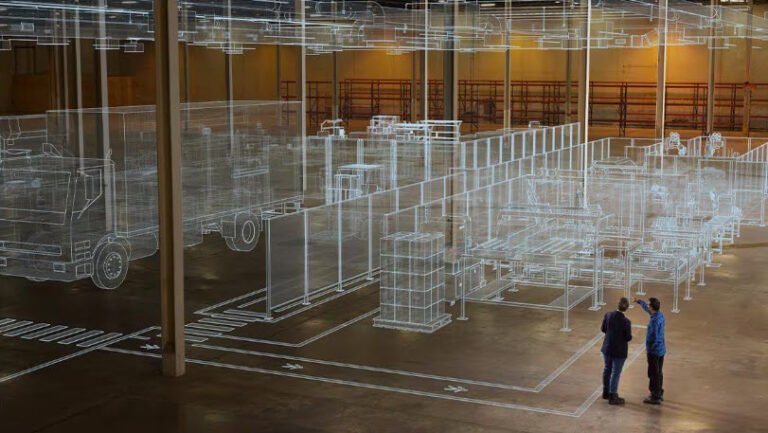

Production bottlenecks, resource constraints, and unpredictable shifts in demand can derail even the best factory planning. Factory simulation helps address these challenges by revealing how a system behaves under real‑world scenarios before costly changes are made. It’s a practical, reliable way for teams to optimize processes and stay ahead of operational risks. Advanced factory simulation tools like Autodesk Factory Design Utilities and Autodesk FlexSim are reshaping how teams design, analyze, and optimize factories.

By integrating FDU’s layout and asset intelligence with FlexSim’s robust 3D discrete‑event simulation capabilities, manufacturers can build a true end‑to‑end digital factory workflow. Let’s take a look at how the two environments connect, why the integration matters, and how factory simulation accelerates smarter decision‑making across production environments.

Why factory simulation matters

Manufacturers increasingly rely on factory simulation to eliminate guesswork. Simulation tools allow teams to test ideas virtually, comparison‑run scenarios, identify bottlenecks, and forecast the impact of changes on throughput, staffing, or material flow.

FlexSim: 3D Discrete Event Simulation Software

Easy-to-use 3D simulation modeling and analysis software with high-end capabilities. Predict and optimize production processes with realistic 3D visuals and data-driven scenarios.

Autodesk FlexSim is specifically designed to help organizations “model, analyze, and optimize real-world systems in a risk-free virtual world,” with capabilities for what‑if scenarios, bottleneck detection, and data‑driven decision‑making. It supports drag‑and‑drop modeling, rich 3D visualizations, logic‑building tools, and advanced experiments to unlock actionable performance insights.

But simulation is most powerful when it seamlessly connects to design environments, especially the tools used to define factory layouts, equipment, and workflows. That’s where FDU becomes a critical part of the story.

The role of FDU in early factory cesign

Autodesk Factory Design Utilities (FDU) allows engineers to design accurate, data‑rich factory layouts using AutoCAD, Inventor, and Revit content. Factory assets like conveyors, robots, racks, and operators can be configured in 2D or 3D, complete with metadata that informs downstream processes.

FDU is extremely effective for spatial planning, layout optimization, and early visualization. However, layout alone does not answer critical operational questions such as:

- How will product flow behave during peak demand?

- Will the line bottleneck at packing? At inspection?

- What staffing configuration delivers optimal throughput?

- How will adding an AGV fleet impact travel times?

Connecting FDU layouts directly to FlexSim simulation closes this gap.

The unified factory asset library: The FDU–FlexSim Bridge

One of the most significant advancements toward true end‑to‑end factory simulation is the Unified Factory Asset Library, which enables seamless interoperability between FDU assets and FlexSim simulation environments.

This means engineered factory assets no longer live in silos. Instead, they become part of a consistent asset ecosystem shared across:

- Factory layout (FDU)

- Mechanical design (Inventor)

- Building design (Revit)

- Simulation (FlexSim)

- Data management (Vault)

- Cloud collaboration (ACC, Fusion)

This alignment is critical for accuracy—ensuring that the equipment modeled in simulation truly reflects the equipment appearing in physical layouts.

One connected factory simulation workflow

By combining FDU’s design capabilities with FlexSim’s analytical power, manufacturers achieve:

- A single source of truth for factory assets

- Faster layout-to-simulation transitions

- More accurate operational models

- Reduced duplication of effort across teams

- Better decision‑making through data‑driven analysis

- Consistent workflows aligned with Autodesk’s broader Digital Factory vision

When your layout tools and simulation engine speak the same language, everything gets easier. Engineers spend less time re‑creating models and more time exploring ideas that actually move the business forward. With FDU and FlexSim working as one, manufacturers finally get the visibility, accuracy, and freedom they need to build better, smarter factories.