IMCO GENERAL CONSTRUCTION

Unlocking new opportunities in the post-construction phase

THE FUTURE OF MAKING THINGS

Share this story

From design and construction to operations and maintenance

IMCO General Construction didn’t start out with the intention of disrupting or upending the constructor-owner relationship. But the company, headquartered in Ferndale, Washington, has been exploring a new way to work with owners that promises great mutual benefits—call it a “post-construction-phase” alliance. In this new model, IMCO has secured a multiyear operations and maintenance (O&M) contract that leverages the expertise developed while building the facility into a stable, long-term opportunity. In turn, owners get superb management of their newly constructed facilities.

A challenging infrastructure project in a remote location

In 2015, as part of an Environmental Protection Agency (EPA) Superfund project, IMCO began work on the Holden Mine Water Treatment Plant, located near Lake Chelan in Washington State’s Cascade Mountains. The jobsite was a copper mine that had closed in 1950. Its wilderness location is so remote that it’s accessible only by boat—about a day’s travel from the nearest metro area.

Autodesk Building Information Modeling (BIM) software, including Navisworks project review software and BIM 360 project management software, simplified management of the project’s entire lifecycle. With BIM tools and processes, the company was able to prefabricate building components to precise specifications, schedule construction-material deliveries, estimate the cost of scheduling changes, plan concrete-pour sequences, and stage the jobsite for production activities ranging from mass excavation to the installation of steel superstructures. And despite breaks in construction for the snowy winter months and during a massive wildfire, IMCO completed the project in less than a year—10 months ahead of schedule.

The water-treatment plant is at a remote site in north central Washington, located a day’s travel from the nearest metro area. Courtesy of Will Austin.

BIM expertise opens up a new opportunity

About two-thirds of the way into the project, the collaboration with the project’s main stakeholder began to shift. “The owner approached us about operating the treatment plant,” says IMCO Senior Project Manager Fred Simmons. “We’d gained their confidence during their long selection process, and especially with our performance during construction.” Selecting contractors for long-term operation contracts is unusual but also likely to become more common. In this new era, contractors are integrated into the design process and seen as a logical extension of BIM lifecycle management—through design, constructability, execution, handover, and finally, operation phases. BIM provides all the information needed to keep the plant working optimally.

For IMCO, operating and maintaining the plant was the next logical step in the project. Courtesy of Will Austin.

IMCO was ready for an opportunity like this. “We’ve been building these facilities for over 30 years and have trained operating staff on numerous occasions,” Simmons says. “So, operating and maintaining a treatment plant was a logical step for us and an opportunity we’ve been looking for. It all came together on this project.”

To operate the treatment plant, IMCO hired full-time staff members working in rotation to operate the plant 24 hours per day, 365 days per year. While on-site, the new IMCO employees live in a lodge built by IMCO and are supported by a full-time medic and cooking staff.

The operations staff were hired and brought on-site before the treatment plant was commissioned and gradually took over as major construction was completed. “It’s going very well,” Simmons says. “The people we’ve hired are some of the best, and they’re making a success of this.” But he’s also quick to point out that success at this level is neither easy nor assured. Simmons feels many factors came together to make this O&M contract viable for both IMCO and the facility owners.

An integrated vision leads to success

“The treatment plant staff are not a ‘division’ of IMCO, they are IMCO,” Simmons says. “All the paychecks are from IMCO, and these employees receive the same support and resources as our employees across the board. Even though their roles are unique, we want total integration into our family-owned company.”

Alongside successful contractor integration, there’s a strong commitment within IMCO to the company’s new direction. “I would say that support for this contract within the company is universal,” Simmons says. “This was evident to the treatment-plant owners, and it was a factor in their decision.”

Simmons emphasizes the importance of good people. “These are all specialty individuals, with extensive experience in treatment and industrial facilities, sought out specifically for this contract,” he says. And to hire good people, you need good people. IMCO’s hiring process took several months, and it was not contracted out to headhunters. Rather, the company depended on current employees who had developed good contacts and on one former, integral employee.

Using BIM software and point clouds captured by a drone-mounted laser scanner, IMCO created accurate 3D models of the Holden Mine site in far less time than with traditional field surveying. Courtesy of IMCO Construction.

“When I heard an employee of ours, who had left to become a construction manager elsewhere, was looking to make a change, I was quick to contact him,” Simmons says. “That helped everything to fall into place. With his known experience, we had a place to start and quickly hired a number of additional qualified staff.” Just hiring wasn’t enough, of course. IMCO made a point of thoroughly onboarding and training new hires—a process that included several working months on-site before the plant was operational.

Know the owner, know the project

Due to the long and thorough selection process, the owners and IMCO knew each other well before breaking ground. And as the actual construction proceeded, they established trust in their collaboration process, which was partly due to the extensive use of BIM.

“Pictures speak a thousand words, and modeling proved to be a very good tool on this project,” Simmons says. “We were able to put models in front of the owners, show them clashes, and work with them proactively to resolve problems. And we updated models based on as-built laser scanning during construction. That enabled very fast-track construction—we reduced an 18-month timeline to just 8 months. That developed confidence that we were a good choice to operate what we were building.”

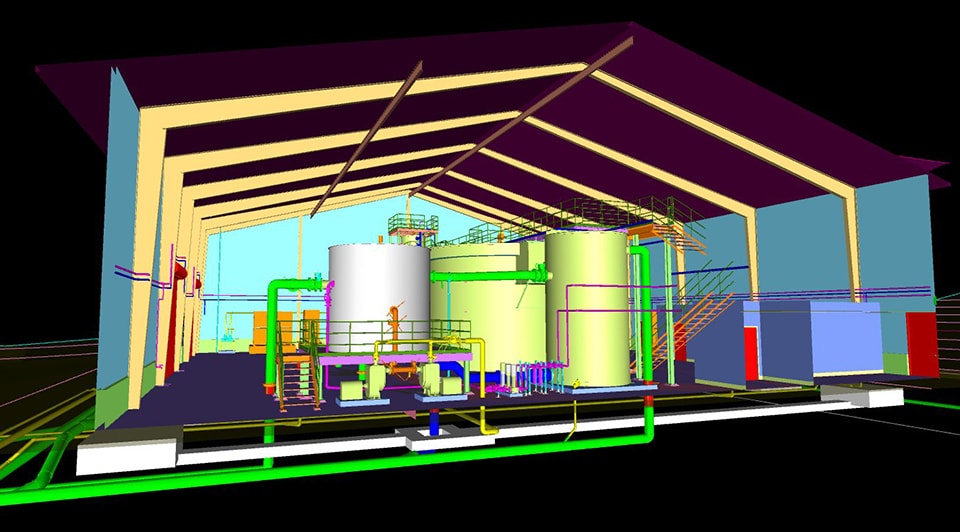

A 3D model of IMCO’s mine water–treatment plant project. Courtesy of IMCO Construction.

Future business opportunities in O&M

Building and operating the mine water–treatment plant provided a virtuous circle of feedback that made for a better project overall. In response to observations made by newly hired operating staff, changes were made during final construction stages. And after the plant was commissioned, the contracting-savvy staff suggested additional modifications for more effective operations.

As a result, IMCO’s foray into this new project territory is something it will want to explore again. “Now that we have the background and résumé, we’ll definitely seek out more contracts like this,” Simmons says. “Especially in mine water–treatment facilities and in remote locations like this one.”

But the biggest impact beyond the improvements to the construction and operation phases was IMCO’s ability to tap into a new O&M revenue stream. By embracing BIM processes in construction, IMCO positioned itself for success in the increasingly connected future of construction.

A version of this article ran previously on Redshift. Photos courtesy of Will Austin.