-

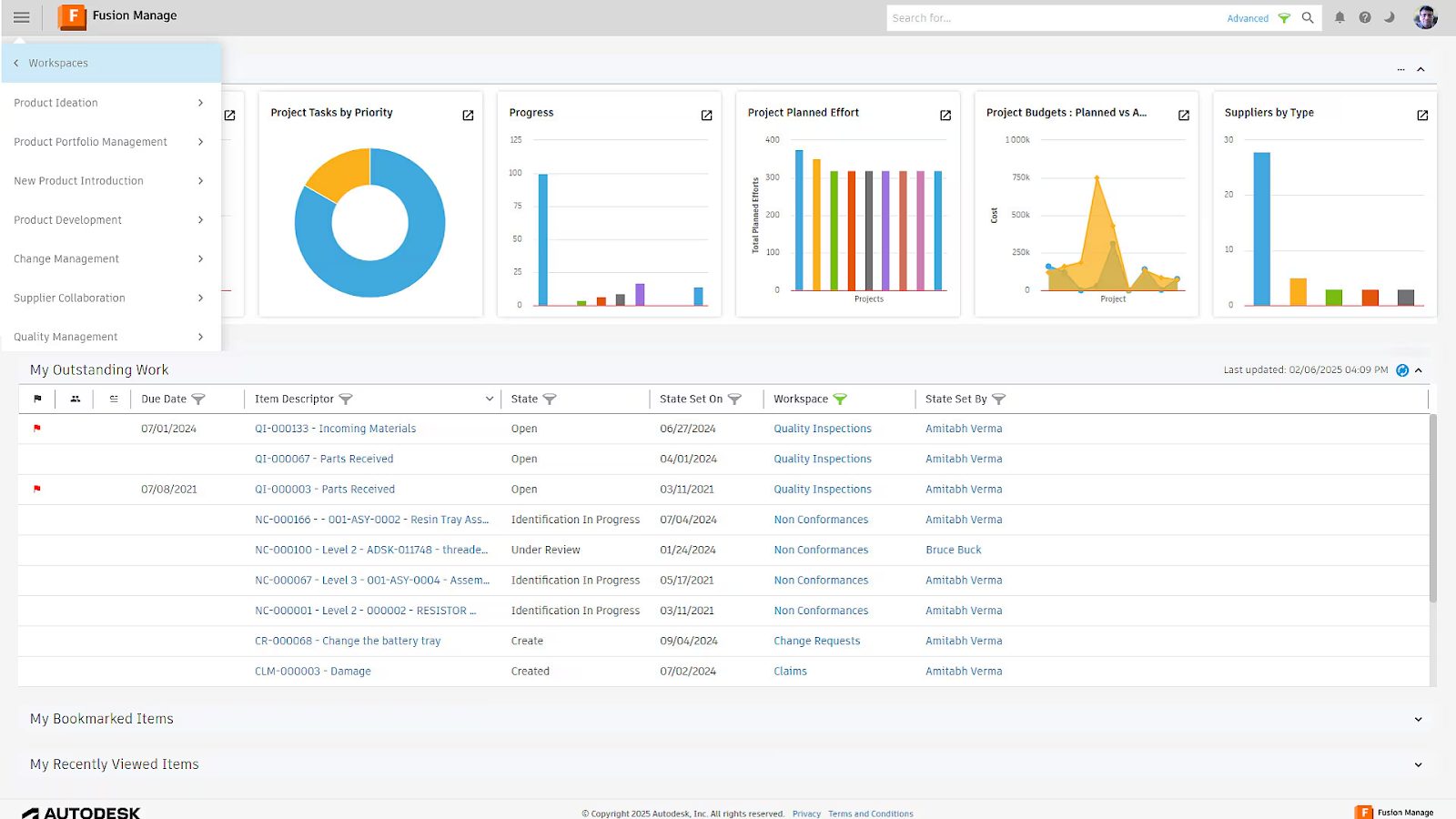

What’s New in Autodesk Vault 2026.2: Work Smarter, Move Faster

Autodesk Vault 2026.2 enhances PLM connectivity with Fusion Manage integration, streamlines data management, and boosts productivity with new sync and workflow features. Autodesk Vault 2026.2 brings seamless connectivity for Vault PLM users with the introduction of the integrated Fusion Manage panel in Vault. Vault 2026.2 also includes a set of targeted improvements designed to make…

Data & Process

-

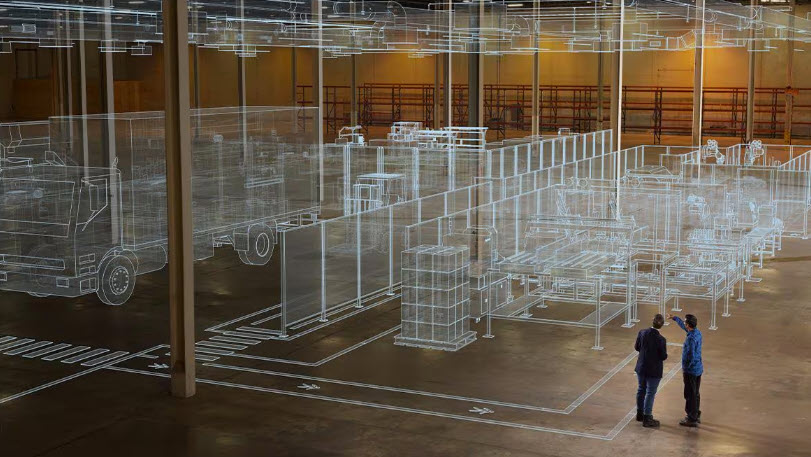

Smart Factories as Business Imperatives

This article explores how smart factories turn real-time data into business intelligence that drives efficiency and agility. It examines the technologies powering this transformation and how Autodesk solutions like Autodesk FlexSim and Fusion Operations enable manufacturers to optimize performance, sustainability, and profitability through connected digital systems. Factory operators are converting traditional factories into “smart” facilities…

Autodesk FlexSim

-

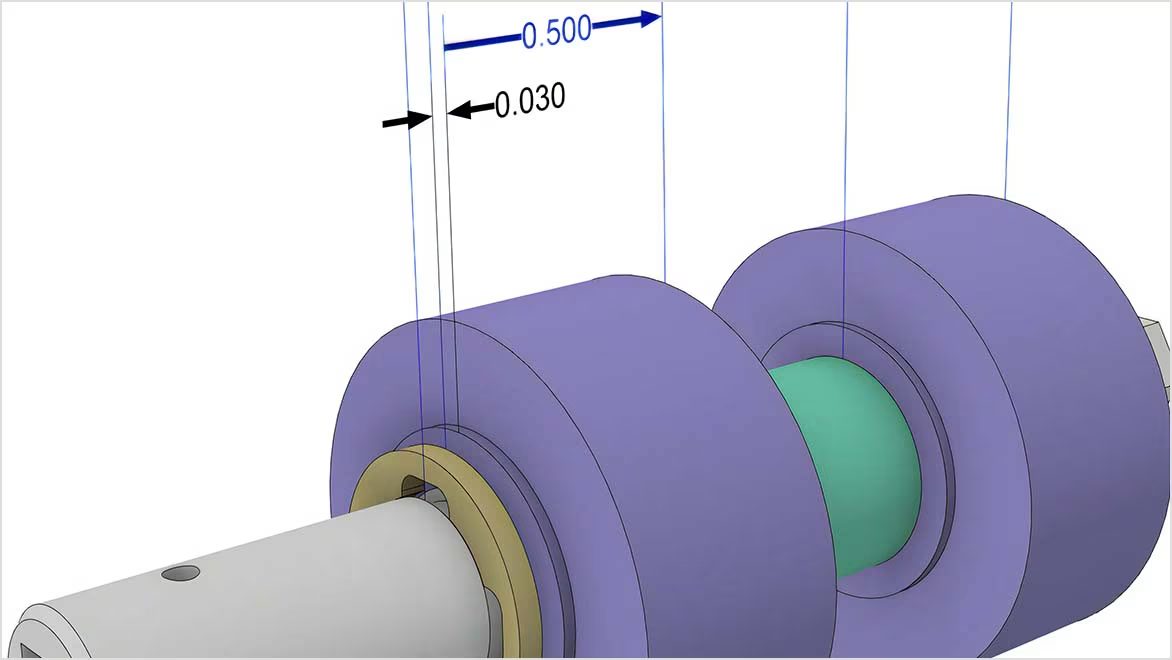

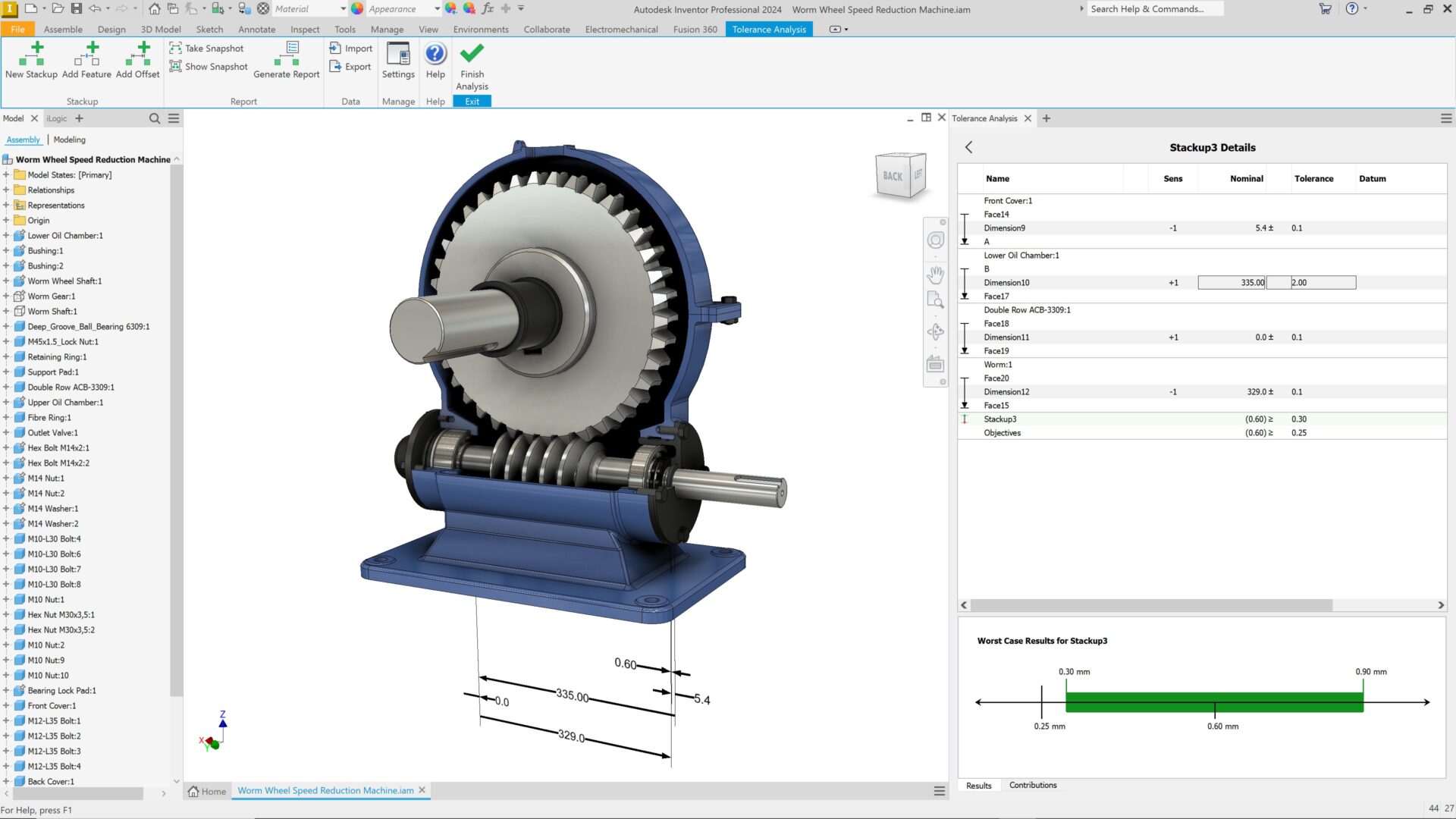

Essentials of Tolerance Analysis for Modern CAD Workflow

This article examines the importance of tolerance analysis in ensuring reliable assembly and controlling manufacturing costs for mechanical design. It discusses how Autodesk Inventor Tolerance Analysis integrates with CAD models so engineers can validate dimensional variation and optimize design decisions early in the workflow. Success in product development is a function of both precision and…

Design & Engineering

-

Cloud Product Lifecycle Management for Distributed Product Teams

This article examines how cloud PLM solutions support distributed product teams by improving accessibility, collaboration, and scalability. It also highlights Autodesk’s cloud PLM tools (Fusion Manage and Vault PLM) and how they facilitate change management to improve supplier collaboration and connect teams across the full product lifecycle. The global design and manufacturing industry is more…

Data & Process

-

Discrete Event Simulation (DES): The Engine Behind Data-Driven Manufacturing Decisions [Update 2025]

Discrete event simulation (DES) enables manufacturers to analyze, model, and optimize complex production systems without disrupting real-world operations. As the manufacturing ecosystem grows more dynamic—with variables like supply chain volatility, custom product demands, and automation—DES provides a virtual sandbox for experimentation, forecasting, and cost optimization. How discrete event simulation (DES) & modeling helps manufacturing make…

Autodesk FlexSim

-

Inventor 2026.2 What’s New

Inventor 2026.2 is another great point release with several enhancements across the board for sketching, part and assembly modeling, and drawings. Thank you again to everyone who contributed their ideas and feedback for all three of our major releases for Inventor 2026. Assembly enhancements Place and Insert command With Inventor 2026.2, assembling components just became…

Autodesk Inventor

-

Ensuring EU MDR Compliance: The Crucial Role of Fusion Manage in Medical Device QMS

Learn how Fusion Manage helps medical device manufacturers meet EU MDR requirements with a flexible, cloud-based QMS that connects design, risk, and postmarket data for continuous traceability and global compliance. Modern medical device companies increasingly rely on quality management systems (QMS) to meet evolving regulatory demands like. In this post we’ll explore how cloud-based Autodesk Fusion Manage takes…

Data & Process

-

Just-in-time (JIT) Manufacturing Benefits [Update 2025]

Just-In-Time (JIT) manufacturing enhances efficiency, reduces waste, lowers inventory costs, improves quality control, and boosts customer satisfaction by aligning production with lean principles. Just-in-time (JIT) manufacturing offers a powerful approach to streamline operations, reduce waste, and align production directly with customer demand. Rooted in lean manufacturing principles, JIT has revolutionized how manufacturers increase efficiency and…

Production

-

Model-Based Definition (MBD) and The Role it Plays in Modern Manufacturing [Update 2025]

Explore the benefits of model-based definition (MBD), its benefits across manufacturing, and how Autodesk solutions can help. For more than a century, 2D engineering drawings were the universal language of manufacturing. They captured dimensions, materials, and tolerances, serving as the primary reference for turning product concepts into physical parts. As manufacturing technologies and product complexity…

Design & Engineering

-

Solve Design Inefficiencies by Shifting from 2D to 3D CAD

Struggling with outdated 2D workflows? Discover how transitioning to 3D design empowers manufacturers to reduce errors, speed up production, and stay competitive with Autodesk’s seamless 2D-to-3D integration. Manufacturing companies face increasing pressure to improve product quality, reduce time-to-market, and streamline production processes. A critical business challenge many manufacturers encounter is the need to evolve from…

Design & Engineering

-

Unifying Factory Solutions for Smarter Production

Explore how Autodesk’s integrated factory production solutions help manufacturers optimize factory layouts, streamline production processes, and improve operational efficiency for smarter, faster factory production. Autodesk is entering a new era of unified production—one where smart collaboration and digital factory solutions converge to transform how products are designed, engineered, and manufactured across industries. By integrating FlexSim with AutoCAD, Inventor Factory Design Utilities, Vault – and introducing…

Production

-

Demand-Driven Success: Lean Production Meets Just-In-Time (JIT)

Lean production and just-in-time (JIT) manufacturing work together to eliminate waste, reduce inventory, and create agile, demand-driven production systems that maximize efficiency, quality, and customer value. Understanding lean production just-in-time (JIT) Manufacturing companies around the world have discovered that lean production and just-in-time (JIT) methodologies represent the most effective approach to eliminating waste while maximizing…

Production