Autodesk Vault PLM enhances data integration across various departments, enabling streamlined processes, improved collaboration, and data-driven decision-making to optimize product development and organizational efficiency.

Data is one of the most powerful assets in manufacturing, driving innovation, efficiency, and a competitive edge. While engineering departments have long used data to design and develop products, other departments can also benefit significantly from accessing and utilizing this rich resource. By extending data beyond engineering, companies can streamline processes, improve collaboration, make more informed decisions, and create better products.

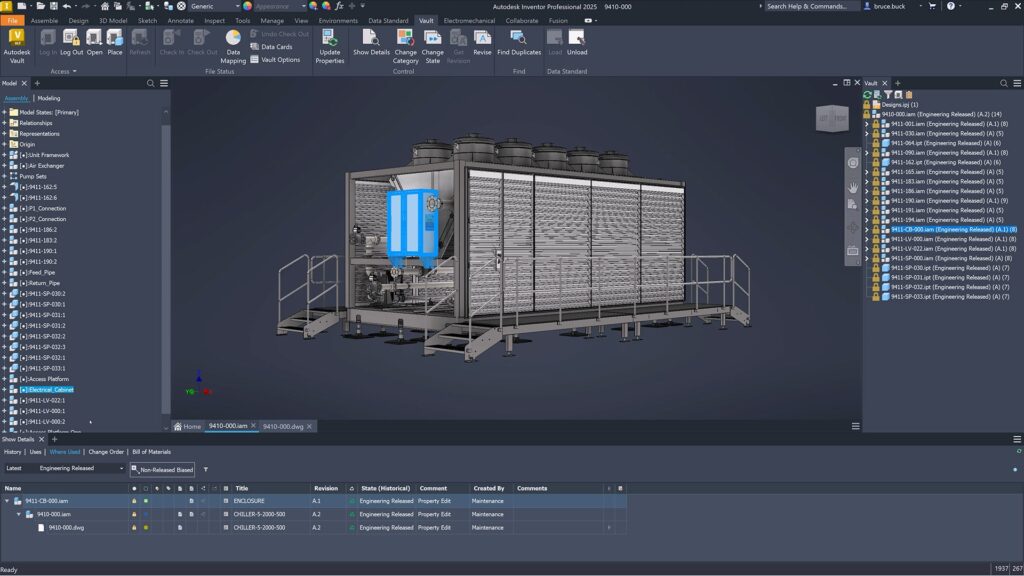

Autodesk Vault PLM helps organizations achieve these goals by integrating data across various departments. In this article, we will explore how Autodesk Vault PLM can help you do more with your data.

The value of data beyond engineering

Engineering departments typically manage a tremendous amount of data during the product development process, including CAD models, design specifications, and material requirements. This data is a necessity for creating high-quality products, but its value doesn’t end there. Let’s take a look at how other departments can use this data to enhance their operations:

- Procurement: Access to detailed design data allows procurement teams to make more informed decisions about sourcing materials and components. They can accurately forecast demand, negotiate better terms with suppliers, and ensure timely delivery of parts.

- Operations: Operations teams can use engineering data to optimize manufacturing processes, improve quality control, and reduce production costs. By understanding the design specifications and material requirements, they can better plan and execute production schedules.

- Quality assurance: Integrating data from various sources allows QA teams to gain deeper insights into potential issues and areas for improvement for the proactive identification of defects and more accurate testing. Leveraging extended data empowers QA departments to deliver better products, improve customer satisfaction, and drive continuous improvement within the organization.

Challenges of data integration

Despite the obvious benefits, integrating data across departments is often challenging. Manual processes, data silos, lack of standardization, and incompatible systems can hinder seamless data sharing. This can lead to inefficiencies, miscommunication, and missed opportunities. To overcome these challenges, organizations need a solution that enhances data integration and collaboration across departments.

How Autodesk Vault PLM Helps

Autodesk Vault PLM is a bundle that combines Vault Professional product data management with Autodesk Fusion Manage cloud-based product lifecycle management. It’s designed to bridge the gap between engineering, procurement, QA, operations and other departments to help organizations maximize the value of their data. Here’s how Autodesk Vault PLM can help:

Centralized data management

Autodesk Vault PLM provides a centralized platform for managing all product-related data. This ensures that data is accessible to all relevant departments, removing silos and improving collaboration. Teams can easily find, share, and update information, leading to more efficient workflows.

Improved collaboration

With Vault PLM, collaboration between engineering, procurement, operations, and QA becomes seamless. Users can share data, track changes, and communicate effectively. This collaborative environment allows teams to work together to achieve common goals.

Enhanced visibility

Autodesk Vault PLM offers enhanced visibility into the entire product lifecycle. QA teams can access up-to-date design and production data to identify potential quality issues early. Procurement teams can make informed sourcing decisions, while operations teams can view detailed specifications to optimize production processes.

Streamlined processes

By integrating data across departments, Autodesk Vault PLM streamlines various processes. QA can leverage data to improve quality control and ensure compliance with standards. Procurement can automate sourcing and supplier management, reducing lead times and costs. Operations can use data to enhance production efficiency. Engineering teams can collaborate more effectively with other departments, accelerating product development cycles.

Data-driven decision making

Access to comprehensive data empowers departments to make data-driven decisions. QA can analyze historical data to identify trends and prevent recurring issues. Procurement can forecast demand and negotiate better terms with suppliers. Operations can use data to identify bottlenecks and implement process improvements. Engineering can leverage all of this feedback to refine designs and enhance product quality.

By integrating Autodesk Vault PLM, organizations can ensure that every department is equipped with the tools and information needed to deliver superior products and drive continuous improvement.