The conversation around artificial intelligence and digital twins in the Architecture, Engineering, and Construction (AEC) industry is reaching a fever pitch. But amid the buzzwords and bold predictions, a more nuanced reality is taking shape. To cut through the noise, a recent industry panel brought together four experts at Autodesk University to ground the discussion in practical application, revealing a landscape that is more accessible, sustainable, and human-centric than the hype suggests.

This blog distills the key insights from that conversation, backed by comprehensive industry data. The expert panel featured a balanced cross-section of the industry:

Their discussion is particularly timely. The "2025 State of Design & Make" report reveals a significant shift in industry sentiment. While 78% of leaders believed AI would enhance their industry in 2024, that number has dropped to 69% in 2025. Meanwhile, concern is on the rise, with 48% of leaders now believing AI will destabilize their industry.

Here are four surprising truths that emerge when we move beyond the hype and into the real world of AI and digital twins.

You can also watch a replay of the class on our Autodesk University site.

The most significant shift in reality capture isn't a single new feature, it's its democratization. Technology once reserved for massive, high-budget projects is now accessible and practical for a much wider range of uses, transforming workflows for firms of all sizes.

Dustin Ridley of DPR Construction shared a telling anecdote about a project where a traditional terrestrial laser scanner was deemed "overkill." His team opted for a more accessible tool that was "good enough" for the design team's needs. The takeaway, according to Ridley, is that "the problem needs to drive the conversation," not the technology. This pragmatic approach is allowing teams to apply the right level of technology to the right problem, maximizing value without breaking the bank.

On the design side, John Gray of Colliers Engineering & Design described how his team used reality capture as an "entry point" to tackle a massive rebranding project, scanning nearly 500 sites in a single summer. The choice of technology was driven by the need for speed and a manageable budget, which are factors that would have been prohibitive just a few years ago.

This increased accessibility is fueled by a broader industry shift. Stephanie Lin of Matterport noted the move toward more flexible, cloud-based SaaS solutions, which lower the barrier to entry and empower small and mid-size firms to compete. Becky Burns of Autodesk framed this trend as the "democratization" of powerful tools, a sentiment echoed in the State of Design & Make report, which states, "Digital tools and standards make it easier to... democratize solutions."

This trend directly addresses the industry's biggest hurdle. According to the same report, cost is the top barrier (44%) to digital transformation. The adoption of more accessible, fit-for-purpose reality capture tools is a direct and powerful answer to this primary industry challenge.

While reality capture is typically valued for its contributions to efficiency and accuracy, its sustainability benefits represent an increasingly important and often overlooked dividend.

Stephanie Lin opened this part of the discussion with a striking statistic: on average, every scan saves 450 miles of travel. This creates a direct and measurable link between adopting reality capture and reducing carbon emissions from transportation.

Becky Burns expanded on this, explaining how accessible reality capture "changes the business case of reuse versus build new." By making it easier and faster to assess existing building stock, firms are better equipped to pursue adaptive reuse projects. The Autodesk Impact Report quantifies this benefit, noting that reusing existing materials can lead to embodied carbon reductions of 75% compared to new construction. A prime example is Sydney's Quay Quarter Tower project, which repurposed 70% of its own materials, saved 13 months of work, and avoided an estimated 12,000 metric tons of CO₂e.

Even seemingly small efficiencies contribute to this green dividend. John Gray pointed to the wastefulness of "old school pen and paper" methods, connecting saved time and fewer site visits to broader resource and energy savings. From the general contractor's perspective, Dustin Ridley explained that the efficiency gains from digital tools lead to better logistics, optimized material estimation, and reduced rework. This directly translates to decreased construction waste, which is a key sustainability goal that the State of Design & Make report identifies as a top action being taken by firms today.

Despite the immense potential of AI in construction, its adoption faces significant friction rooted in fear, confusion, and a lack of trust that is palpable across the industry.

Dustin Ridley shared a powerful example from the field: project specs that explicitly state "no AI on the project." He noted that such generic prohibitions are becoming unworkable, as AI is already integrated into standard construction management platforms. The real issue is that owners need to be far more specific about their concerns, which often stem from a lack of understanding.

John Gray elaborated on this confusion, observing that "95% of people think automation is AI." This fundamental misunderstanding is compounded by his primary concern: security. "Where is our data going? Who has it? How are they using it?" These questions reflect a deep-seated anxiety about data privacy and intellectual property.

In response, technology companies are working to build guardrails. Becky Burns pointed to the establishment of "Trust Centers" by companies like Autodesk as a way to provide transparency. The Autodesk Impact Report outlines core "Trust principles for AI"; those systems be responsible, transparent, accountable, reliable, and safe and secure, that are becoming the industry standard for demonstrating a commitment to ethical AI.

Ultimately, overcoming this friction requires clear communication. Stephanie Lin emphasized that winning over hesitant owners requires being "hyper detailed about use case and usage." By demystifying the technology and focusing on specific, tangible benefits, project leaders can build the confidence needed to move forward.

These concerns are validated by industry data. The State of Design & Make report found that trust in AI technology has decreased by 11 percentage points year-over-year, driven largely by anxieties around cybersecurity and data privacy.

The future of AEC is not about replacing human expertise; it's about augmenting it. The most exciting developments are those that combine the computational power of AI with the irreplaceable insight and critical thinking of industry professionals.

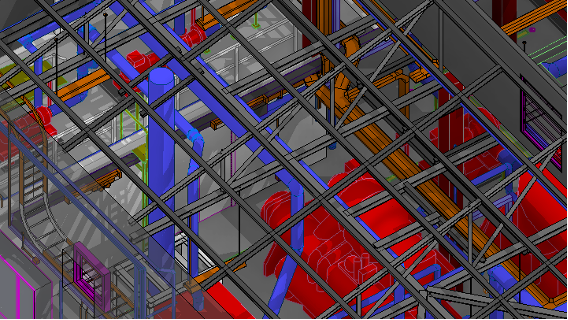

John Gray described the "holy grail" of scan-to-Revit, as the ability to generate a BIM model directly from reality capture data, as a future that is tantalizingly close. He noted, "we can see it and the horizon, like it's, it's coming." This vision isn't about eliminating modelers but about freeing them from tedious as-built documentation to focus on higher-value design and problem-solving.

Becky Burns painted a picture of a circular economy for building materials, where scanning a building before deconstruction creates a digital "marketplace" of reusable components. This marketplace would include rich model data, allowing designers to drop a salvaged beam or window directly into a new Revit design, complete with all its specifications.

This evolution is fundamentally changing the nature of AEC jobs. Dustin Ridley predicted that AI will "revolutionize the role of VDC," a shift from manual execution to digital oversight that is already reshaping hiring priorities. This is confirmed by the State of Design & Make report, which shows that 46% of leaders now see the ability to work with AI as their top hiring priority.

Stephanie Lin connected these advancements to the operational phase of a building's life, which accounts for 70% of its total lifecycle costs. Here, digital twins act as a powerful data source, empowering facility managers with insights to make better, more proactive decisions. She noted that while AI helps us move beyond the "limits of human intelligence," it does not replace it.

This sentiment was perfectly summarized by Blaine Buenger in the State of Design & Make report:

"I don’t think AI will ever take over an engineer or a scientist or a designer’s job. I think AI will be a fantastic assistant and boost efficiency and productivity."

The collective wisdom of the panel points to a clear and powerful conclusion: the AEC industry is maturing in its relationship with technology, moving from a view of simple automation to one of sophisticated human augmentation. Reality capture is becoming more accessible, its sustainability benefits are creating tangible value, and the initial hype around AI is giving way to a more pragmatic, trust-focused approach to adoption. The future is not about replacing people but empowering them.

According to the panelists and supporting industry data, accelerating this future hinges on three pillars:

As these tools become more integrated, they promise to handle the rote, repetitive tasks that consume so much time and energy. This raises a crucial question for the industry's future. As Veerendra Patil noted in the State of Design & Make report:

"We need artists. We need creative thinkers. We need problem solvers. We don’t need button pushers, because those are the tasks that will get automated."

As technology automates the tedious, how will the AEC industry reinvest its greatest asset; the creative, problem-solving capacity of its people?