One Click Metal Is changing the metal 3D printing game for smaller manufacturers

See how the young German manufacturing company One Click Metal uses metal additive technology to disrupt the design game.

Mark de Wolf

February 28, 2023 • 7 min read

Germany’s One Click Metal has created an affordable, safe, and simple way for small and medium enterprises (SMEs) to accelerate product development.

The company’s compact machine uses the latest generative design tools to transmute metal powder into business gold.

3D prototypes appear in just a few clicks, using next-generation metal additive tech that previously only big companies with big budgets could afford.

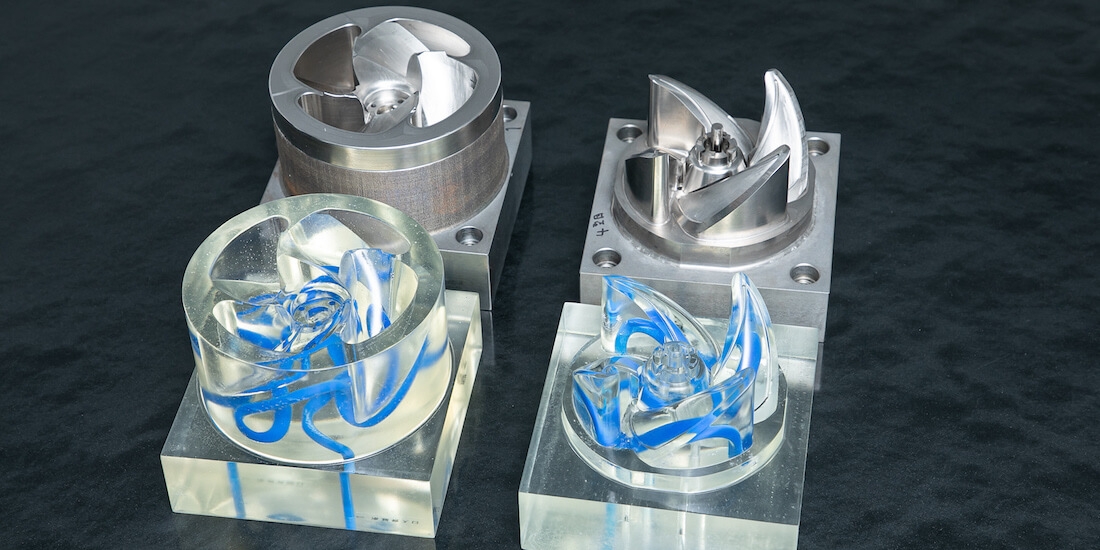

Shaping metal into forms used to mean firing up a massive forge to superheat raw ore, sending hot rivulets of lavalike alloy down a gutter to cool in a silicon mold. Today’s manufacturing firms can achieve similar outcomes without the mess and energy consumption using laser powder bed fusion (LPBF)—a type of metal additive manufacturing fed by purified metal powder.

Although 3D printers can be found everywhere from schools to factory floors, metal 3D printing isn’t so common—in part because printing metal has been punishingly expensive. The technology has improved steadily for more than a decade, but it’s still complex to use compared to mainstream 3D printing, as well as reliant on large and complex machines.

German company One Click Metal wants to change all that. It has created a metal-additive printing system called BOLDseries that is affordable, portable, and easy to use, without compromising on part quality. The mission is to give thousands of small and midsize enterprise (SME) manufacturing firms that form the backbone of Europe’s economy a way to quickly and affordably prototype high-performance products and components and design serial parts that benefit from metal 3D printing’s possibilities.

Making metal printing affordable

Originally an R&D unit of global laser and manufacturing tools giant Trumpf, One Click Metal spun off into an independent company when leadership saw an opportunity to transmute the parent company’s laser expertise into disruptive business gold.

The raw materials for most 3D printers come from the same stuff as plastics: moldable and plentiful polymers. But nylons, polycarbonates, and styrenes turn out a porous material that has a relatively weak underlying chemical foundation. Printing with metal is a different game: Heavy industrial products like turbine blades and vehicle engines need stronger stuff. Only metal has the potential to provide a firm crystalline microstructure that can withstand industrial-scale stress, heat, and pressure.

One Click Metal’s vending machine–size units use an industrial-grade metal powder that’s safely packaged into standardized cartridges. Plug one in, load or tweak a 3D design file created using a tool such as Autodesk Netfabb, and click “print.”

The MPRINT 3D-printing unit’s 200-watt fiber laser allows great productivity and precision with complex metal applications. Combining two functions into one machine, the MPUREpro machine unpacks a component and removes any unused powder with direct powder contact, and its integrated, autonomous ultrasonic sieve recycles processed powder into a supply cartridge, which can then be used again. The MPRINT units are also versatile enough to create their own parts. Using Autodesk Fusion 360, One Click Metal was able to design and output the sophisticated driver component that opens and closes the powder cartridges.

“Due to the limited space in the assembly area and the specifications of the motor manufacturer, only a feather key can be used for power transmission,” says One Click Metal CEO Gerrit Brueggemann. “Either the keyway must be created by pushing or broaching, or the feather key has to be milled into the component. The additive design and process is the better solution here.”

Instead of making drivers individually, One Click Metal used Netfabb to stack the parts. When designing the part, care was taken to ensure the parts could be stacked without being too difficult to support. For that reason, the parts are always stacked on top of each other rotated by 180 degrees, resulting in surfaces that are easily supported. “That really reduces the time and cost of production,” Brueggemann says.

A growing market

One Click Metal’s entry into the metal additive printing market may be perfectly timed. Grand View Research valued the global metal-3D-printing market at $3.52 billion last year, with annual growth projections of 23.9% expected between 2022 and 2030. According to the firm’s recent report, “Metal 3D printing has benefitted significantly from the growing necessity of rapid prototyping and advanced manufacturing practices.”

NASA has also jumped on board. The US space agency says it intends to 3D print more than 80% of its future rocket engines using metal additive systems. Elon Musk’s SpaceX has also announced investments in 3D metal printing to augment the company’s manufacturing capabilities.

Construction could be the next frontier. In 2021, Imperial College London installed and opened the world’s first 3D-printed metallic bridge in Amsterdam.

The challenge: bring metal to the masses

One Click Metal arrived on the scene just in time—but there were serious barriers along the way. One Click Metal’s business model depends on bringing the power of 3D metal to the SME market, making what has been an out-of-reach purchase cheaper and easier to deploy in smaller settings.

Space, expense, complexity, and safety have been major hurdles for metal 3D printing. One Click Metal has jumped them using cloud-based collaboration tools that brought the parent company’s laser experts and supply chain partners together to problem-solve and provide complementary design input.

“We identified three key barriers to taking metal additive printing to a wider market,” Brueggemann says. “The first was the metal powder itself. The handling process is a big issue, especially for small companies that use the machine right next to their conventional manufacturing machines. For quality purposes, the powder can’t be allowed to get wet or contaminated.”

The second challenge was how to design a 3D metal printing machine for both functionality and affordability. The third was making a machine that wouldn’t require extensive training. “We knew it had to be easy to use,” Brueggemann says. “Many companies wouldn’t be using it 24/7 from the beginning—they start with first ideas like prototypes that result in products over the long term. At the industry level, the initial investment costs have been a major reason for or against the cost of 3D metal printing.”

To that end, one of One Click Metal’s key innovations has been a standardized cartridge for metal powder. This eliminates the need for open powder handling, ensures quality, and enables reclamation for reusing powder.

“The whole process is similar for all LPBF machines on the market, but we knew it is not enough just to have a good machine,” Brueggemann says. “The whole process is still new, so we brought it all together with a vision of the one-click method the customer wants.”

Flying into the future

The machines are currently optimized for outputs in the 150 cm–by–150 cm range, which leaves a lot of room for innovation. One Click Metal has used its MPRINT machine to create a working drone that integrates multiple flight components into a single, highly complex metal form.

“One of our employees is a drone pilot, and he had the idea of using the machine to create an optimized metal drone,” Brueggemann says, noting that the company then contacted Autodesk’s generative design team for advice on how to do it. “We looked at all the individual parts of a drone and tried different designs that could incorporate them into a single frame. Fusion 360 was great at pointing us toward approaches that optimized and also helped control costs.”

Collaborating in the cloud

As the company prepares for another busy year of global trade events and sales engagements, Brueggemann says collaboration is going to be key to One Click Metal’s growth.

“In the sales process, we and our sales partners help customers find the right solution for their problem, providing cost calculations and additive design advice,” Brueggemann says. “Fusion 360 and Netfabb are ideal for that. They have the best features and the best price. Also—it keeps getting better and better.”

He adds that Autodesk’s programs for educational institutions provide another source of value. “We are working with universities and students on various projects,” he says. “This way everyone can work as a team in the cloud using the same design platform.”

About the author

Mark de Wolf

Mark de Wolf is a freelance journalist and award-winning copywriter specializing in technology stories. Born in Toronto. Made in London. Based in Zürich. Reach him at markdewolf.com.