ZELEROS

The revolution of high-speed transportation

FUTURE OF MAKING

Share this story

The transport of tomorrow: faster and efficient

The new transport method is called Hypeerloop by Zeleros. The Zeleros company was born to face the challenge of devising a new vehicle that, in addition to being high-speed, would reduce travel time, be more sustainable and consume fewer resources. Using advanced tools and software from Autodesk, Zeleros was able to present its Hyperloop prototype that promises to be the tomorrow’s transport.

Innovation as an Hyperloop Engine

Zeleros is the Spanish company that develops Hyperloop, already considered "the fifth means of transport". Their focus on vehicle optimization allows for reduced infrastructure costs and safer working pressures for passengers. Zeleros has already a wide private and public support, collaborating with companies such as Renfe and Altran, research centers (Universitat Politècnica de València, CIEMAT, UPM) and is backed by investors such as Plug and Play, Angels Capital and ClimateKIC. Zeleros is currently preparing to build its own 2-kilometre test track in Sagunto to demonstrate the high-speed system and is involved at European level in promoting the standardization of the system.

Watch video

“We've managed to reduce weight by around 30% and increase strength by 50% by implementing Autodesk's Generative Design technology.”

—Juan Vicén, Co-founder and Director of Communications, Zeleros

Connect cities in minutes

Zeleros aims to connect cities and logistics centers more quickly and sustainably. Their scalable system that reduces infrastructure costs makes is possible to travel long distances in a matter of minutes, a revolution in passengers and goods transportation.

Integration of the Zeleros Hyperloop vehicle with reality

From challenge to reality

Zeleros faces the challenge of opening a new market and developing a new method of transport. Although the Hyperloop idea is more than 200 years old, there are many integration challenges, because the different aspects have never been tested together. However, today's enormous technological advances in large vacuum systems, control and automation make it possible to materialize Hyperloop conveyor systems.

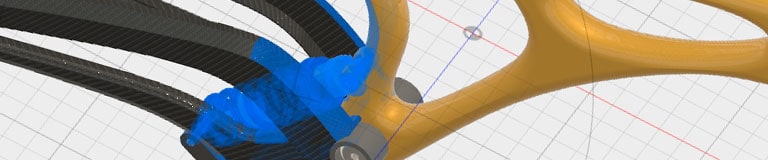

Design optimization with AGD for traditional CAM manufacturing with a 3-axis machine and 2 setups

The fifth means of transport

To overcome these challenges, Zeleros researched the high-speed systems market and concluded that infrastructure is the key element that affects the total cost of the project and, therefore, its viability. Zeleros' objective is to design a system that reduces the complexity of the infrastructure by incorporating part of the technologies into the vehicle.

Zeleros also applies the best of existing industries (rail, aerospace, energy, infrastructure) to accelerate system development. This brings advantages such as operation at pressures like those of aircrafts, which are safe for passengers, and with previously welltested safety measures, which ensure the safe operation of the system.

“Working with Autodesk solutions allows us to design more efficiently.”

—Juan Vicén, Co-founder and Director of Communications, Zeleros

What Autodesk products does Zeleros use to meet your challenge?

Zeleros uses several software and simulation tools for development, including Autodesk Eagle, Inventor Professional and Fusion 360 - Generative Design.

What has Hyperloop's success meant for Zeleros? What has been the real impact of Autodesk on Zeleros?

The use of advanced development tools accelerated the development of the Hyperloop transport system designed by Zeleros, which has received important awards in numerous international forums for its disruptive approach that reduces implementation costs.

Thanks to Autodesk tools, Zeleros improved substantially, taking a step forward in development and improving efficiency during this phase, which will allow the prototype to be tested on the 2 km test track at high speed.

Zeleros commercial vehicle design

How was the collaboration between Autodesk and HP?

Basically, in the construction of the vehicle, Zeleros is interested in developing solutions that minimize weight and maximize strength. Thanks to the collaboration between Zeleros, Autodesk and HP, a structure for the levitation system was optimally designed and manufactured using additive printing, which reduces weight by 35% and increases resistance by 50% compared to the first design. This demonstrates the potential of these tools.

What makes this means of transport interesting and/or unique?

The peculiarity of the Hyperloop type transport system is that it allows land connections at speeds of up to 1000 km/h with minimal energy consumption, as friction within the tubular infrastructure is reduced thanks to the low-pressure environment and levitation systems.

In addition, Zeleros' design further increases its efficiency by reducing the costs of building, operating and maintaining the infrastructure thanks to its system configuration, which integrates most of the technologies in the vehicle, thus reducing the complexity of the infrastructure. In this respect, Zeleros offers a unique solution that in turn allows the company to operate at pressures that are safe for passengers. The enormous environmental, economic and social benefits promote the competitiveness of nations and cohesion between countries and continents.