Hou-Tech Co., Ltd.

Maximizing efficiency with design automation

DESIGN & MANUFACTURING

Share this story

Residential door manufacturer uses iLogic technology in Autodesk Inventor to enhance productivity and efficiency while reducing human errors

Hou-tech, based in Gero, Gifu, Japan, manufactures residential doors, storage systems, fittings, and interiors for Japanese-style rooms. This global operation began in 1956, when Hou-Tech made a wider variety of products from shipping containers to wooden frames for clocks. The move to making residential doors began in 1973 after meeting a customer’s special request. Demand rose quickly, fueled by high growth in the housing market during the country’s economic boom. Today, Hou-Tech has operations in Japan as well as China, Indonesia, and many other countries across Asia.

Hou-tech uses innovation and cutting-edge technology to make products that create relaxing spaces. Photo courtesy of Hou Tech.

Complex products with short lead times

Hou-Tech offers two product lines: standard and custom-made. The custom products are significantly more challenging to design, requiring precise details within unique drawings that are based on the standard products. The design department has 12 people who produce approximately 3,000 new drawings of custom-made products every month. This works out to 250 drawings per month, for every designer.

While they use AutoCAD LT for more basic drawings, they began using Autodesk Inventor for development of their complex custom product line. Inventor has significantly improved their design process, making it easier for designers to keep up with the pace of complex drawings that typically have short lead times and involve highly detailed customer requests.

Exquisite sample doors in the Hou-Tech showroom at the company’s headquarters. Photo courtesy of Hou Tech.

Inventor streamlines the process

One of the most indispensable features of Inventor for Hou Tech is iLogic, the design automation technology that gives designers a head start when creating custom products that are based on their existing standard product line. OBIC Co., Ltd., an Autodesk distributor, helped the Hou-Tech team develop an iLogic template based on actual Hou-Tech product models. OBIC also provided two days of training to help Hou-Tech designers get the most out of the tool, as well as full implementation support.

“Since my days in vocational school, I have been fascinated by 3D modeling,” says Mr. Masashi Imai, who leads the design division of the Hou-Tech engineering department. “3D models make it much easier and clearer to visualize the design, so we did not hesitate to shift to Autodesk Inventor. In addition, the iLogic template from OBIC helped us increase the number of designs we can produce.”

iLogic reduces process time by 20%

When Hou-Tech first implemented Inventor, it was used primarily to create models for residential doors, the company’s main product line. Now, however, use of Inventor has expanded to the company’s storage systems, which also take advantage of design automation with iLogic.

“It would not be possible for us to handle products with extremely short delivery times without iLogic,” says Mr. Imai. “We only have three to four days between order acceptance and delivery in some cases. We make every effort to shorten the design process and leave as much time as possible for production. Before iLogic, it took about a day to complete one drawing. With the power of iLogic, it takes only two to three hours. We have reduced overall process time by about 20% thanks to iLogic.”

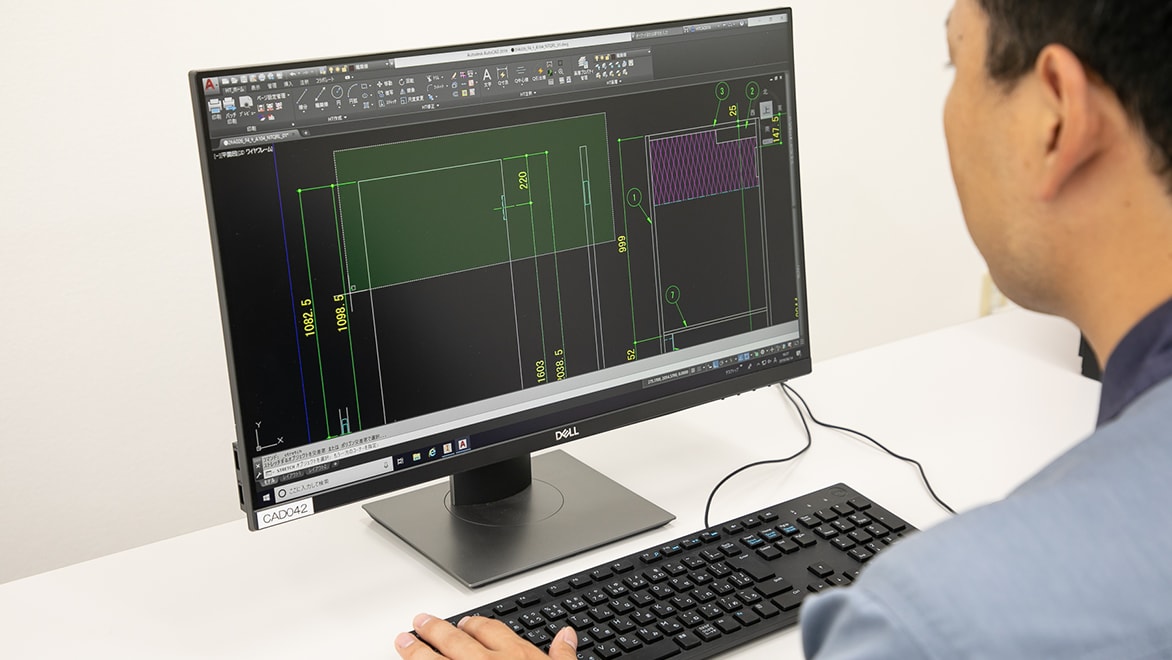

The sales team uses AutoCAD LT to ensure smooth communication with customers about product requests. Photo courtesy of Hou Tech.

Zero human errors

Another achievement with Autodesk Inventor is the lack of human errors in the models. “There is always a chance of human error with manual tasks, even the simplest ones,” Mr. Imai says. “I believe the risk of error is much lower in our design process with Inventor. In fact, we’ve made zero mistakes in the drawings so far. This is amazing.”

“Before iLogic, it took about a day to complete one drawing. With the power of iLogic, it takes only two to three hours. We have reduced overall process time by about 20% thanks to iLogic.”

—Masashi Imai Design Section Head, Engineering Department, Hou-tech Co., Ltd.

Equipping sales for smooth customer communications

Using Inventor and iLogic isn’t the only way Hou-Tech has improved operational efficiency. Previously, the design team had to wait for a final approved paper order sheet from a salesperson in order to kick off the design process in AutoCAD LT. Equipping the sales team to create the first pass within AutoCAD on their own has been a game-changer. This up-front data, called a sales drawing, is only used as the base of the actual design for production. But it features interactive data that helps the sales team communicate with customers smoothly and efficiently, so no detail is missed.

Hou-Tech headquarters in Gero, Gifu, Japan, famous for its Onsen hot springs. Photo courtesy of Hou Tech.

Making even better use of design automation

Charging forward, Hou-Tech is aiming to improve efficiency even more. They have created a “virtuous cycle” so that each employee’s incremental improvements in drawing and modeling help improve the efficiency of the entire company. Hou-Tech is also exploring an internal system that will make better use of the design automation tools available within iLogic, as well as ways to use BIM within Inventor.

Related products

-

Professional-grade product design and engineering tools for 3D mechanical design, simulation, visualization, and documentation.

-

Best-in-class tool for 2D CAD drafting, drawing, and documentation. Subscription includes AutoCAD LT on desktop, web, and mobile.