Explore how Autodesk’s integrated factory production solutions help manufacturers optimize factory layouts, streamline production processes, and improve operational efficiency for smarter, faster factory production.

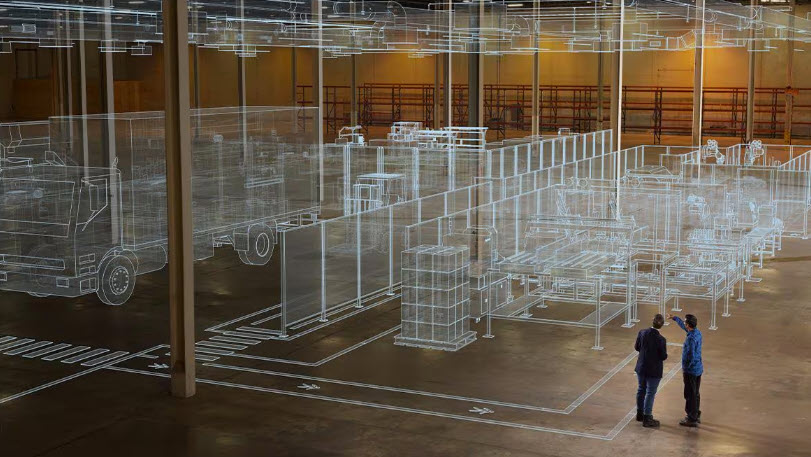

Autodesk is entering a new era of unified production—one where smart collaboration and digital factory solutions converge to transform how products are designed, engineered, and manufactured across industries. By integrating FlexSim with AutoCAD, Inventor Factory Design Utilities, Vault – and introducing new workflows with FlexSim and Fusion Operations – Autodesk is reshaping how teams plan, build, and optimize factory operations at every stage, connecting data and workflows to drive smarter, faster, and more competitive production outcomes.

Expanding collaboration in factory production

Today’s manufacturing is inherently collaborative, but Autodesk’s approach takes it further—connecting not just designers and engineers, but also production engineers, factory layout planners, building designers, construction teams, operations, and many more stakeholders. This broad collaboration fosters a holistic view of the entire product and factory lifecycle, so that every perspective contributes to smarter decision-making and smoother workflows.

Convergence of factory and operations solutions

Autodesk has worked to seamlessly unite architecture, engineering, construction, and manufacturing into one integrated ecosystem. Whether production planning begins with a 2D layout, a scanned brownfield site, a building shell, or 3D CAD assets, teams can now build a single operational definition that connects every facet of a factory’s lifecycle—design, construction, and operation.

FlexSim integration: Bridging design and execution

A major advancement is FlexSim’s integration with AutoCAD, Inventor, and Factory Design Utilities. This means manufacturers can start with an existing floor plan—such as adapting a consumer products factory for a new air fryer—and customize it efficiently for new production needs. By connecting FlexSim with Fusion Operations, real-time telemetry from existing processes can inform simulations and layout optimization, helping meet objectives like reducing cash conversion cycles or minimizing in-process inventory.

Since FlexSim now uses Autodesk’s asset library and integrates with Vault, moving from optimized layouts to detailed engineering in Inventor is seamless and efficient.

Scaling with Inventor’s advanced assembly performance

The latest enhancements in Inventor support modeling factory assets and layouts developed in FlexSim at an industry-leading scale. The introduction of no-code programming with iLogic makes it easy for teams to automate configurable models such as jigs and fixtures, reducing repetitive tasks and accelerating shop floor agility.

Unified data exchange and construction integration

With improved data exchange capabilities, Inventor can now integrate directly with Autodesk Construction Cloud. This integration enables model coordination services that combine Inventor and Revit data, helping factory operators detect clashes and resolve issues between manufacturing and building models before construction begins, ultimately saving time and money.

Continuous operational improvement with Tandem

All these capabilities operate within a shared, real-time platform—Autodesk Tandem—where stakeholders across planning, design, construction, and operations collaborate continuously. This collaborative environment drives ongoing process improvements and operational excellence across the factory lifecycle.

Embracing disruption as opportunity

Autodesk embraces disruption as a catalyst for innovation. AI-powered workflows enhance human creativity and expertise, so that teams can design and engineer faster, automate routine tasks, and bring innovative products to market more efficiently. Connected data and convergent workflows reduce errors and accelerate production, delivering a significant competitive advantage.

Autodesk’s unified platform, powered by advanced AI and industry-leading collaboration tools, give manufacturers the tools they need to build self-adapting factories. By automating mundane tasks, teams can concentrate on meaningful work and drive innovation at scale. This connected, data-driven future is reshaping manufacturing and production for greater agility and responsiveness.