At the heart of the Netherlands’ railway network, a critical junction in Zuidwestboog Meteren is undergoing a massive transformation. The project – part of a broader programme to enable high-frequency rail traffic – focuses on a complex intersection where the Betuweroute, a dedicated freight line from Rotterdam Harbour to the German border, meets the passenger lines connecting Utrecht and Den Bosch.

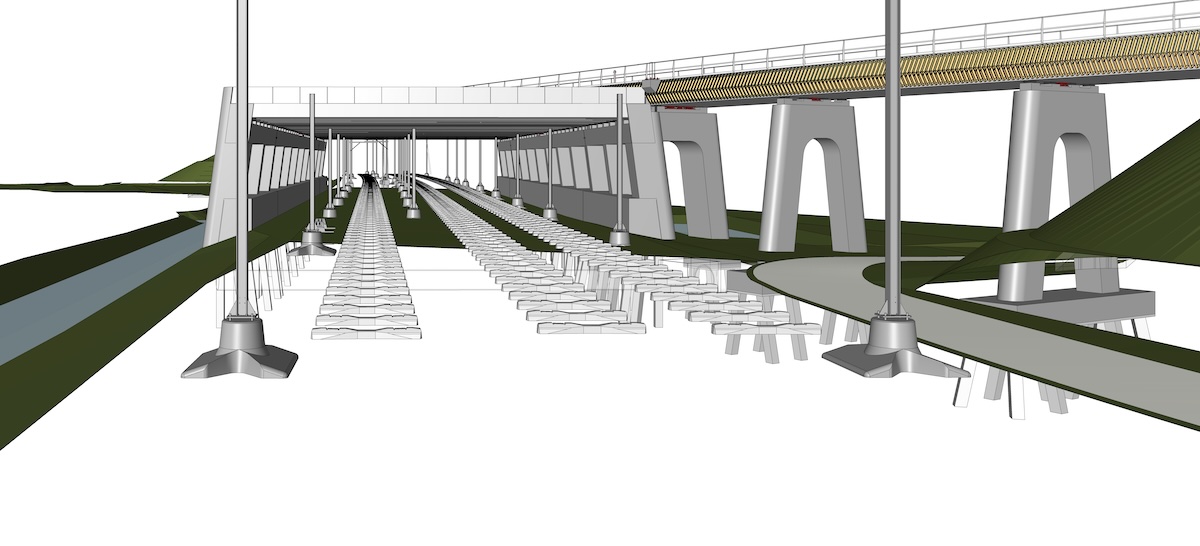

For Van Hattum en Blankevoort, the concrete contractor division of VolkerWessels, the task is as high-stakes as it is technically demanding. “We’re responsible for construction works underneath the rail line itself,” explains Pieter Prins, BIM Manager at Van Hattum en Blankevoort. “That includes soil work, concrete foundations, and bridges – all covering nearly 3km of track.”

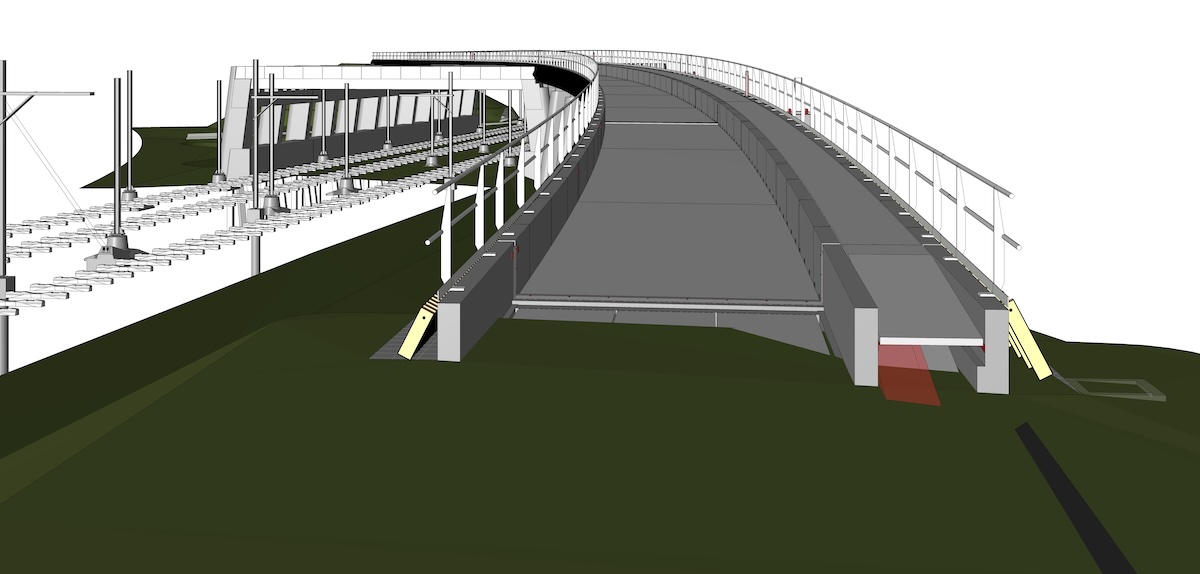

Along that line is the impressive Pergola construction, a bridge extending almost 200 metres designed to let freight and passenger trains cross paths safely. “The Dutch infrastructure market has a separate challenge,” explains Pieter. “We’ve got a massive volume of work and significant grey-out – a lot of knowledge held by experienced people is expected to be lost on short notice. That’s why it’s essential to collect information centrally, contribute widely, and recruit where we can.”

“Autodesk Construction Cloud is already central to our work. It represents a major step forward.” - Pieter Prins BIM Manager, Van Hattum en Blankevoort

The ProRail programme in Zuidwestboog Meteren focuses on improving capacity at a key crossing, with nearly three kilometres of work in a tight area where phasing and live infrastructure shape the plan. Van Hattum en Blankevoort’s scope sits beneath the track, which makes coordination especially unforgiving: small mismatches between disciplines can become large fixes once construction sequencing is underway.

To manage the immense data and collaboration requirements of the Meteren project, VolkerWessels transitioned to Autodesk Construction Cloud (ACC). Since they had previously used BIM 360, the move to ACC was a natural evolution that let the team centralise every facet of the design and construction process. By using a suite of integrated tools – including Revit, Civil 3D, and Navisworks – all funnelling into ACC, VolkerWessels created a unified common data environment for the project.

“In the past, remarks would get lost in email,” says Pieter. “With ACC, none of the comments are lost during the review processes. It connects everything together.” This transparency is crucial not only to ensure accurate feedback on the Meteren project, but also to archive and collate mission-critical knowledge for use in the future.

One of the project’s most innovative aspects is its integration of Autodesk Workshop XR. Using Meta Quest 3 VR glasses, the project teams conduct virtual safety walks of the construction site before a single cubic metre of concrete is poured. By pulling coordination models into a virtual environment, engineers and site managers can walk through the proposed phasing of the project, allowing them to interact with the design and identify potential gaps or safety hazards at an early stage, even before physical implementation.

“It’s a good way of working and a low-barrier way of exploring Workshop XR,” notes Pieter. “Setting up VR experiences like this really helps us a lot. We address issues through the issue module, which interacts directly with ACC for tracking and registration – so everything is completely integrated.”

The shift to a centralised, cloud–based workflow has yielded measurable improvements in both communication and speed. According to Pieter Prins and Peter Kanninga (Director Integral Projects), ACC has been vital in achieving Van Hattum en Blankevoort’s goals.

“We’re always looking for innovative solutions that boost collaboration, cut failure costs, and increase productivity,” says Pieter. “Digital workflows have already halved our physical review rounds, taking the average down from four to just two. Real-time access through the Autodesk Desktop Connector and Revit Cloud Worksharing has also slashed wait times for retrieving and syncing models by 30-40%. Most importantly, by integrating Model Coordination and clash detection in ACC, we’ve resolved 75% of clashes before physical construction even starts”.

Beyond these high-level wins, VolkerWessels uses standardised templates and instructions, letting them onboard new team members and external contributors in just 30 minutes. Design leaders also use model coordination to search for clashes themselves, solving interfaces at their desks before they enter the final design phase. The team uses the “Bridge” module in ACC to exchange models and data with third party providers, such as those designing the overhead power cables.

The project’s set for a phased implementation through 2027-2028, involving redirecting highways and the Betuweroute freight line. Meteren’s ongoing success is supported by a strong partnership between VolkerWessels and Autodesk, using a specialised coaching programme to master new developments like Dynamo for Revit and Civil 3D. By replacing fixed assumptions with a data–driven simulation of the site, VolkerWessels is ensuring a smoother rollout and a more resilient rail network for the Netherlands.

“Autodesk Construction Cloud is already central to our work,” says Pieter. “It’s being deployed on all scales of project – it represents a major step forward.”

By transitioning to a unified common data environment, VolkerWessels is able to bridge the gap between complex engineering disciplines and real-world implementation. The integration of Autodesk Construction Cloud allows the team to resolve 75% of clashes before construction begins, halving physical review rounds and ensuring that critical institutional knowledge is preserved for the future of Dutch infrastructure.