A construction punch list is a vital element in every project. At some point, no matter how much of a joy (or hell) it’s been, the project must come to an end. When it does, it’s not enough to simply watch it fade away in the rearview mirror; you have to make sure the i’s have been dotted and the t’s have been crossed—and that means a construction punch list. If you haven’t yet implemented this in your checklist of successful construction project closeout, it’s time to do so today.

But as most steps in construction, it’s easier said than done. The construction industry has proven time and again that they’re lagging behind other sectors when it comes to technological implementation. That could mean your current construction punch list isn’t working, or that you don’t use one, neither of which is ideal–especially when you have clients counting on you to deliver a high standard of work.

The first step in cleaning up your punch list game? Understanding the basics. Below, we provide a definition of a punch list, what’s included in them, which phase of the process they’re used in and who’s responsible for their oversight. With a better understanding of why they’re important in construction, you’ll be able to refine your process and streamline your project closeout.

We discuss:

The definition of a punch list in construction, also known as a snag list in the U.K., is a document showing work that still needs to be done on a project. This is an important construction document that is completed and given to an owner or general contractor at handover once a project has reached substantial completion.

Another fun fact and mini history lesson is that the term punch list comes from the antiquated process of actually punching holes in a list to mark which items needed fixing.

Another fun fact and mini history lesson is that the term punch list comes from the antiquated process of actually punching holes in a list to mark which items needed fixing.

A punch list usually contains an abundance of information about each item, presented in a methodical way that makes it easy to tell what needs to be done and by who. Each punch list item usually has a punch number and descriptive item name assigned to it, a longer description if needed, and details of the item owner – the person who has responsibility for the task. Start dates and dues dates are also usually shown alongside each construction punch list item, as well as the current status of the item, like whether it is in progress or completed. A punch list may also assign a priority level to each task, as seen in our punch list template.

A construction punch list can feature many different types of work, and these vary depending on the nature of the project in question. Some examples are the testing of fixtures, appliances and doors, and windows. Other common punch list items might relate to fixing damaged or imperfect work, like cracks, defects, and leaks. Sometimes a punch list calls for the addition of items from the original design which have been so far left off, or the removal of on-site items like trash and equipment.

Typically, construction punch lists are for small fixes, because the majority of large issues have already been fixed or addressed previously through a change order. Nonetheless, however minor the changes are, it’s incredibly important to execute your list correctly so your project is given the finishing touches it needs to be considered complete.

You can also learn more in this quick video:

While punch lists are not strictly speaking mandatory, as pointed out by Construction Claims Monthly, they are a widespread and traditional process that occurs toward the end of construction projects.

As the phrase “substantial completion” would suggest, a list is made only when the project is considered nearly finished. As such, punch list items are usually confined to minor tweaks, and typically major fixes have already been addressed. Once this point has been reached, says Compton Construction, it is the general contractor’s job to set up the punch list walkthrough.

During the walkthrough, the owner or client attends to point out issues they see. The general contractor is usually present on these visits to explain changes from the original specifications and to note issues that need fixing. Usually, designers and/or architects attend the walkthrough as well to check that the building matches the original design specifications. If anything doesn’t conform to the original specs because the client requested a change, the architect is also there to address that.

Although there are many parties involved in the oversight and execution of a construction punch list, there are two main phases: making it and addressing it. All stakeholders have a role in both phases, though some are more heavily involved in each phase than others. So just who is responsible for ticking off each punch list item? While this obviously will vary a bit by project description and relevant stakeholders, here’s the basic breakdown of who does what:

Once the construction punch list has been completed and distributed to all involved parties, time is allotted for fixing and another walkthrough is scheduled with both the general contractor and owner present. In a perfect world (or project), there are no new items found on the list, and each item that was originally placed there has been addressed. However, the owner will need to sign off on the punch list for the work to be considered fully completed.

Looking for an easy downloadable template for your punch lists? Download our template:

Here are some of the many benefits of using a construction punch list:

A report from Autodesk and Dodge Data & Analytics survey explored a few key areas to understand the processes and technology used by today’s contractors to manage the quality and closeout of their projects. First, it looked at how contractors manage closeout activities with punch list software. While traditional projects typically punch list at the end of construction, the survey also examined projects that deployed “punch list-as-you go” (i.e., punch listing continually throughout the construction process as parts of work are completed). Finally, the respondents were also asked about the frequency and impact of problems getting off the job.

How are construction punch lists being managed on jobsites today? Take a look at some of findings from the report:

The goal of construction punch lists is to ultimately get to zero—meaning every punch list item is officially crossed off and the project is officially closed out.

But how do teams get to cross off the last list item before everyone has officially tapped out? The key to getting to zero faster is in how you design and manage your lists. Below, we’ll take a look at six winning strategies to take punch list writing and management to the next level.

Read more: How Clayco is Making "Zero Punchlists" a Reality

Generally, the punch list isn’t created until after the walkthrough is complete. Nonetheless, this doesn’t mean that punch list writing needs to happen towards the very end of a project. Instead, it works better to start generating a punch list earlier on in the project as a regular check in on construction quality.

Think about using a punch list checklist right from the kick-off of the project. When implemented at the start of a project, they can be used to create workflow and standards for starting on the right foot. This way, everyone is on the same page and knows what needs to be done at every stage of the project. They even go a step further and make sure that everyone knows which items on the punch list they are accountable for well before project closeout.

It’s smart to design a rolling list, or "punch list-as-you-go," that adapts to the project as it unfolds. This model includes consistently checking work duties during the entire project. Each task should be assigned with a specific closeout schedule for every task.

Laying out the many aspects of the project also shows whether there are holes in the specifications or contract that need to be addressed. During the project, you should consistently meet with the project owner or stakeholders to know what needs to be done before handoff, so their specifications and project requirements are being met.

Conducting regular construction site inspections, or “punch walks,” will support your goal of getting to a zero punch list faster. One thing that crucially delays projects in the closeout stage is inferior construction quality. But a crucial aspect to remember is that quality should be built in, not an afterthought at the end of a project. When you have standards and quality checks along the way, you reduce the need for expensive rework and delays at the end of the project.

Even using a punch list format for your inspections is a fantastic way to align your team on quality throughout construction. Punch list writing fits the goal of quality control well. Its checklist nature is perfect for giving quick oversight as well as documenting exactly what needs to be fixed and whether it has been completed.

To carry out this management strategy, it’s wise to create a specific list that addresses safety and quality measures that can be reviewed during jobsite visits. If possible, it helps to involve a wide range of team members from the general contractor, designer and even owner to make sure the project is being done to expectations.

Punch lists have long been relied on in the construction industry, yet they are starting to evolve to fit modern times. The days of paper punch lists are over–or at least they should be. Paper creates massive inefficiencies and leaves construction team’s open to more risk and errors. If your company wants to be at the top of your game, it’s time to embrace cloud technology and punch list applications.

Identify construction punch list software to keep your team on track and make it possible for you to easily check off and track issues directly from the field. One option is adopting construction collaboration technology that is powered by the cloud. Punch list software can be even more powerful if it is made for mobile devices so that team members can easily track and use from their smartphones and tablets.

Punch list applications make real-time communication possible, even when team members are in different locations. Rather than wait to receive paper lists, the entire team can stay on top of task completions when they happen. This makes for faster and more efficient punch list management for your construction project.

Ownership and accountability are critical concepts in effective construction management. As mentioned, it’s essential to create a punch list checklist that you implement early on in a project. But it won’t streamline or guide your project if no one knows what they’re responsible for. That’s why it’s essential to assign punch list items to specific people or teams and to make sure accountability is built into the punch list management process.

In this area, technology helps the process of managing a punch list. Construction software, like Autodesk Construction Cloud mobile, is available to so you can assign, alert and track people for the specific items they are accountable for. Software for punch lists can also increase visibility so that everyone else on the team can see who’s responsible if questions arise. This method helps keep everyone on the same page and holds people responsible for their punch list items.

To employ this strategy for your team, give each person the appropriate details he needs, including the due date for completion of each task. If required, liability can be included in the contract in case a particular party does not complete their end of the bargain.

Concerning overall punch list management, an experienced team member should be the one to create and manage the administration of the list as this is a vital component to project success. This person should thoroughly understand the scope and magnitude of the work. They should know which tasks are needed to get done and who to assign to each one. They should have the relationships to get the job done and have the authority to resolve problems on their own as they arise. You should empower this person and let them know you trust them while getting across the importance of the job.

A central goal of every project is to avoid exceeding the construction budget. But often, budgets overruns occur when just trying to close out the project. Alternatively, setting a budget for the punch list in advance can be a helpful tactic to keep a project on budget. It also helps advance construction punch lists faster because there are fewer questions about where the money needs to come from to complete. Of course, setting up this budget as part of the initial project allocation is most effective.

Overall, the benefits of setting up a budget for a construction punch list in advance include:

You may feel a great sense of relief when you check off your final punch list item. But don’t get too comfortable until everyone agrees that the project is complete. When you are sure that the job is done, you might find that the owner, architect or another member of the project team has other thoughts.

If this happens, don’t take the feedback personally. Be flexible and handle the changes or issues professionally. Work to resolve them efficiently and make sure every team member is satisfied. In the long run, this tactic will be better for business. At the end of a project, a successful construction punch list is one of the biggest impressions you will leave. Within reason, don’t sacrifice your image and good name to stand your ground.

With so many small fixes to address, especially in large projects, most companies have started using dedicated software or a punch list app to help them efficiently manage their closeout work. Punch list software makes it possible for lists to be completed in real time on mobile devices so companies can execute and close out projects with unparalleled efficiency. In fact, punch list applications make it possible for contractors and owners in commercial, heavy civil and other industries to collaborate, collect and share project information from desktops or mobile devices through the entire project lifecycle.

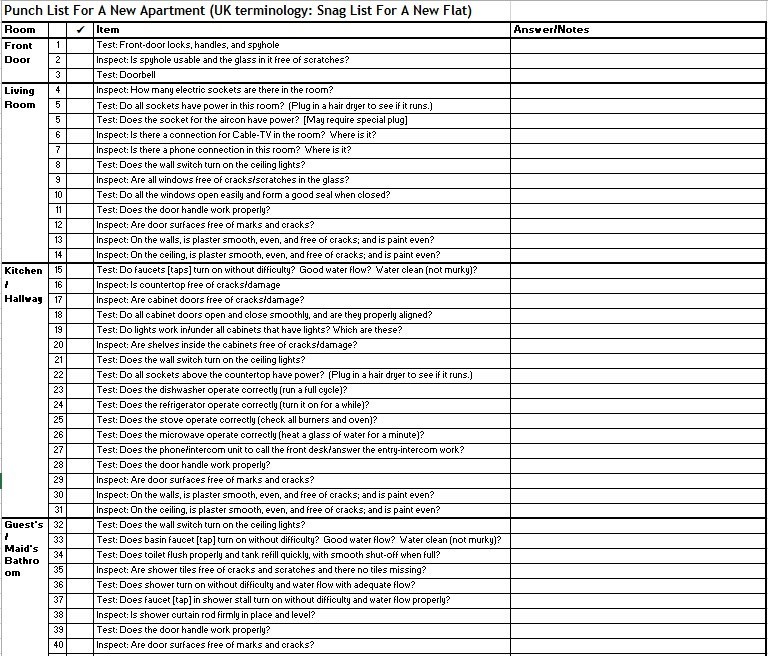

A punch list checklist could be created in an Excel spreadsheet or Google Sheet and look like this:

Download our punch list example template, here:

Instead of PDF templates, try using mobile punch list software so teams can track and collaborate on tasks throughout the entire construction process facilitating a more efficient closeout.

So, what are you waiting for? Make the switch to digital punch list software.

Punch list software like Autodesk Build can be of great benefit during a walkthrough. Rather than recording punch list items on paper or on a voice recorder to note down later, you can create items directly on your phone or other mobile device as you walk through. From there you can add necessary details, assign item owners, and even attach relevant photos. Not only can this save time, but it can also help to make sure that list items are captured and stored in one central place, ready to be actioned.

The construction industry is evolving, and so should construction punch list strategies. Ultimately, the modern ideal is to remove the old-fashioned notion of the process. Outdated and inefficient management of punch lists doesn’t result in customer satisfaction and can mean a scramble to complete a long list of unfinished tasks at the end of a project. By adapting the idea of a list as something to keep track of throughout the project, the project can run smoothly and everything on the punch list checklist is finished by the end. The way to truly embrace this new method is to streamline management by using new practices and technology like a construction punch list application.

Whether you’ve been using outdated methods or haven’t been prioritizing your punch lists, it’s time to put down that old-fashioned tape recorder and notepad and refine your current process. With a smoother, more up-to-date process with the help of punch list software, you’ll be able to move to project closeout in record time.