Kennametal simplifies tooling for precision manufacturing with digital data exchange

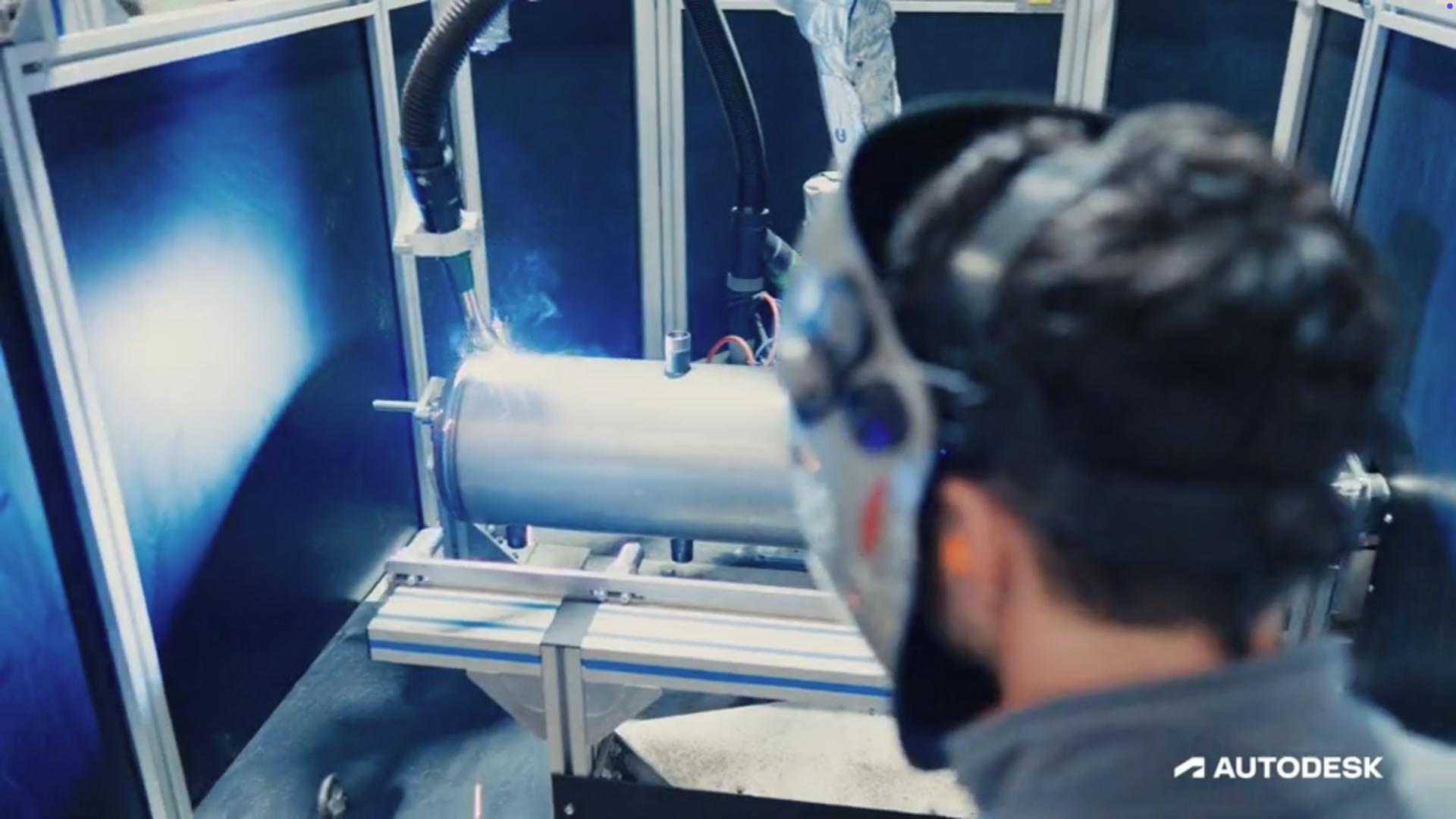

Global tooling and wear solutions company Kennametal streamlines precision tool manufacturing for its customers with an automated online ecosystem.

Markkus Rovito

April 30, 2025 • 6 min read

Industrial manufacturing of parts for high-performance industries like automotive and aerospace demands absolute precision.

Kennametal develops and manufactures solutions to meet these stringent standards, and is moving to make these solutions even more accessible to small and midsize manufacturers.

Digitalizing the manufacturing value chain will help close the growing skills gap in manufacturing and increase efficiency. Kennametal is leading the digital transformation with a unique user experience on its website where manufacturers can access the company’s tooling offering and technical expertise, as well as an enhanced digital machining suite.

At the highest level of precision manufacturing, adjoining parts must fit together as if they were perfectly matched. In the high-performance industries where precision matters most—such as automotive, medical devices, aerospace, and energy—the acceptable tolerances for manufactured parts can be up to 10 times finer than the width of a human hair.

It’s these and other precision-driven industries that Kennametal, a global supplier of high-performance tooling and industrial materials, serves in more than 60 countries. Kennametal manufactures tooling solutions for making the thousands of precision components needed for modern machinery marvels like electric cars, wind energy turbines, or jumbo jets.

It’s fitting, then, that the chief technology officer (CTO) leading Kennametal through its digital transformation also appears to be a perfect match for the job. When she was a young girl growing up in Terre Haute, IN, Kennametal CTO Dr. Carlonda Reilly was fascinated with playing in her grandfather’s basement and garage workshops.

“He had all kinds of tools and gadgets to make things,” Dr. Reilly says. “While I excelled in math and science in school, it was really with my grandpa that I cultivated a passion to understand how to make those things we use in everyday life.”

Decades later, the chemical engineering PhD has been inducted into the Women in Manufacturing Hall of Fame and is helping to make Kennametal’s almost 90 years of expertise in precision tooling solutions more accessible to manufacturers, despite the growing generational skills gap and the traditional barriers to entry for small and midsize enterprises (SMEs).

Data availability for bridging the skills gap

Many of Kennametal’s precision industry customers face thousands of part- and component-engineering challenges while completing a single product. Each part needs to meet stringent requirements, and whether it’s a blisk (bladed disk) for a jet engine or a mounting part for the same engine, the same level of scientific and technological expertise is required.

Kennametal has thousands of products specialized for cutting complex shapes into titanium, aluminum, steel, or emerging lightweight materials like carbon fiber-reinforced plastic composites. These include tools for hole-making, milling, and turning; holders; and adapters. Kennametal also offers the capability to use additive manufacturing in the solution.

Each of these tooling solutions carries an enormous amount of data derived from Kennametal’s engineering expertise. For example, the company’s HARVI™ 1 TE Solid Carbide End Mill may look to the untrained eye like an ordinary drill bit, but it’s actually an award-winning innovation of manufacturing engineering lauded for its performance and flexibility of use. “This tool is a thing of beauty to me,” Dr. Reilly says. “Every aspect that we design into the tool, the material we select, every angle or curvature, surface finish—all of it—has a purpose in delivering performance.”

While Dr. Reilly prizes Kennametal’s accumulated precision manufacturing expertise, she is also leading the effort to make that data and expertise more widely available—to SMEs, for example, for which precision manufacturing traditionally has been less cost-effective to pursue. There is also the growing need to preserve the expert legacy of a generation of manufacturing professionals who are at or approaching retirement age, contributing to a widening skills gap.

“We all know about the trend where experienced programmers and operators are retiring,” she says, “and this loss of know-how is resulting in a growing skills gap. This trend will have more impact within small and medium job shops, which rely heavily on external tooling experts like Kennametal. So, we have been asking how we can extend our technical reach to support these customers effectively.”

An important part of the answer is an automated ecosystem that integrates Kennametal’s tooling data into Autodesk Fusion. This reduces the time and inaccuracies associated with passing such tooling data manually. As an example, when a small or medium job shop gets a request to make thousands of a particular part, they often have a tight timeline but not a lot of resources for figuring out how to make the part efficiently. Kennametal can develop a tooling solution quickly for the job shop to do its own CAM and CNC programming.

“Our vision is to simplify the process, to give those customers all the information they need in the initial processing steps, with the goal of making their part right the first time,” Dr. Reilly says. This ensures that even as the workforce ages, manufacturing can continue to evolve with automation and digitalization.

Automated collaboration optimizes precision tooling

This digitalization in manufacturing has to be done with a purpose in mind, Dr. Reilly says. To unlock the best opportunities for your business, “make sure you know what challenge you are trying to solve that truly addresses the needs of the customer.”

Because Kennametal has been on its own manufacturing digital transformation journey for several years, digitizing its copious tooling data, the company is poised to take advantage of the new business opportunity on its website.

Kennametal.com, with an enhanced digital machining experience, gives manufacturers access to all of Kennametal’s unique tooling expertise and manufacturing capabilities, with the data also integrated into Fusion software. Customers can provide a 3D model of the part or component they want to make, along with the type of manufacturing machinery they have, and the Kennametal machining platform automates pre-manufacturing steps of CAM simulation optimization to find the most cost-effective and efficient tooling package and machining toolpath strategies. If customers use the Kennametal data inside Fusion, all the tool data can move back and forth through the design, simulations, and CAM toolpaths automatically in one place.

Allowing customers to interact directly with the machining platform on Kennametal.com liberates data flow. When passing data manually, Dr. Reilly says, the data exist in silos. Thus, moving the data throughout the manufacturing value chain is time-consuming, and inefficiencies often arise. “The inefficiencies can lead to various issues,” she says, for example, “initial tool breakage, poor part quality, and very frustrated operators. We want to eliminate the silos.”

Kennametal’s ongoing transformation journey

Like any digital transformation journey, Kennametal’s is an ongoing process. The company continues to capture more of its tooling data digitally and add to its Kennametal.com functionality and Fusion integration. New technologies and capabilities, such as AI data analysis, will help this process advance. “AI will give us the ability to fulfill our ultimate vision of making the part right the first time,” Dr. Reilly says.

Precision manufacturing continues to push the boundaries of what can be made, while market forces demand that these complex outcomes happen more efficiently: faster, more accurately, and more sustainably. Dr. Reilly recognizes that Kennametal’s solutions will have to drive and ride the wave of progress along with its customers.

“The applications within our target markets are becoming more sophisticated,” she says. “So the manufacturing solutions will also need to evolve. And despite there being an aging population and a skills gap, we are confident that digitalization and automation will be able to address these challenges effectively.”

About the author

Markkus Rovito

Markkus Rovito joined Autodesk as a contractor six years ago and joined the team full-time as a content marketing specialist focusing on SEO and owned media. After graduating from Ohio University with a journalism degree, Rovito wrote about music technology, computers, consumer electronics, and electric vehicles. Since his time with Autodesk, he’s developed a great appreciation for exciting emerging technologies that are changing the world of design, manufacturing, architecture, and construction.