Continuous Composites’ 3D-printing technology is all science, no fiction

Learn how Continuous Composites' novel curing method, unique molecular binding, and multimaterial printing ability may transform additive manufacturing.

Drew Turney

June 15, 2016 • 5 min read

Continuous Composites, an Idaho-based company, has developed a 3D-printing technology that can print complex structures in one step using multiple materials.

The technology, called continuous scaled manufacturing, uses ultraviolet light to instantly cure epoxies, creating a hard molecular bond much faster than most 3D extrusion processes.

This method gives the ability to print unique geometries and is 10 times faster than its closest competitor.

The process eliminates the need for post-manufacture assembly, and the company aims to advance the technology further.

Imagine 3D printing a car, the wall of a building, an aircraft wing, or some similarly complicated structure all in one step—not just the metal, concrete, or carbon-fiber shell, either, but with everything like power conduits, plumbing, fuel lines, rubber seals, and moving parts intact.

Sound like science fiction? Thanks to a revolution in the making, Coeur d’Alene, Idaho–based Continuous Composites believes it’s just around the corner.

The company has worked with carbon fiber, Kevlar, fiberglass, fiber optics, and continuous copper wire, and its secret sauce is the ability to print multiple materials concurrently to produce a ready part, all the composite pieces in situ as it emerges from the 3D-printing device. Continuous Composites calls this process continuous scaled manufacturing—a step beyond traditional additive manufacturing.

As you might guess (and as the company’s website suggests), the applications for this technology are nearly endless, and Continuous Composites CEO Jeff Beebout says that he and Chief Technology Officer Ken Tyler are ready to take on all of them. “We’re past the prototyping and proof-of-concept stage,” Beebout says. “It’s now ready to be developed for market.”

From epiphany to innovation: The birth of Continuous Composites

After some early-days exposure to 3D printing—along with a computer-science degree and CAD experience under his belt—Tyler was working in the boat industry when he had his lightbulb moment. “I was looking at the maker movement, melting plastic together, and thinking, ‘There’s got to be a better way,’” he says.

Like the mythical apple falling on Sir Isaac Newton’s head, Tyler was walking past a piece of fiberglass he’d fabricated the night before when a stray strand of epoxy fiber “stabbed the hell” out of him. “I thought, ‘Okay, this is stupid; why are we not printing with this stuff?’” he remembers.

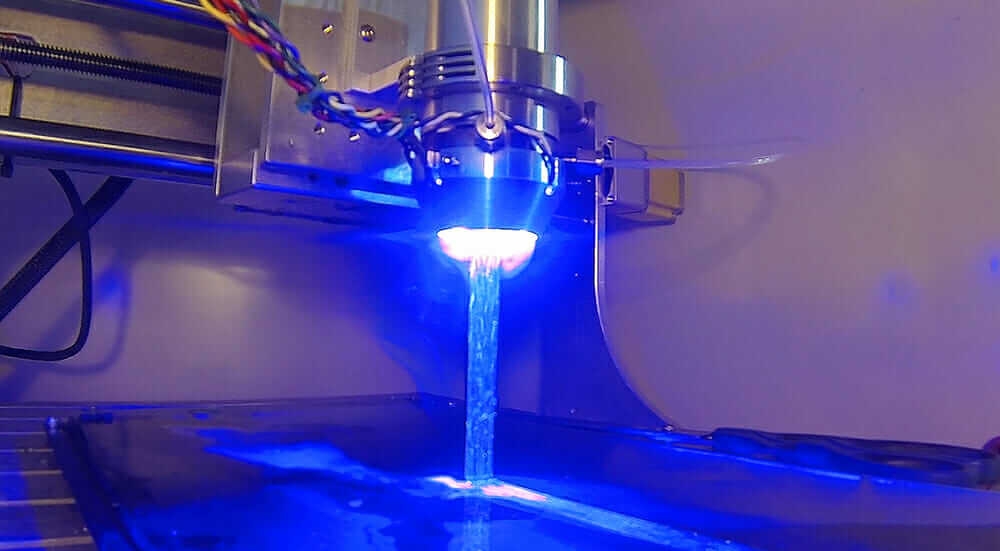

It led Tyler to the research of ultraviolet (UV) light to cure and harden epoxies (a common practice in mass-produced electronics), and he wondered why it couldn’t be done with 3D-printed epoxies. While working three jobs in the boat industry, he spent his nights writing the patent, and the basis for Continuous Composites was born.

Speed, flexibility, and groundbreaking innovations

The first piece of the puzzle is in the thermo-set epoxy the company is using. “It’s much stronger,” Tyler says. “Plastic is basically the same molecular shape as you heat it and cool it, but when epoxy is cured, there’s a chemical reaction, and you get a new molecular shape. It binds to other materials better than plastic.”

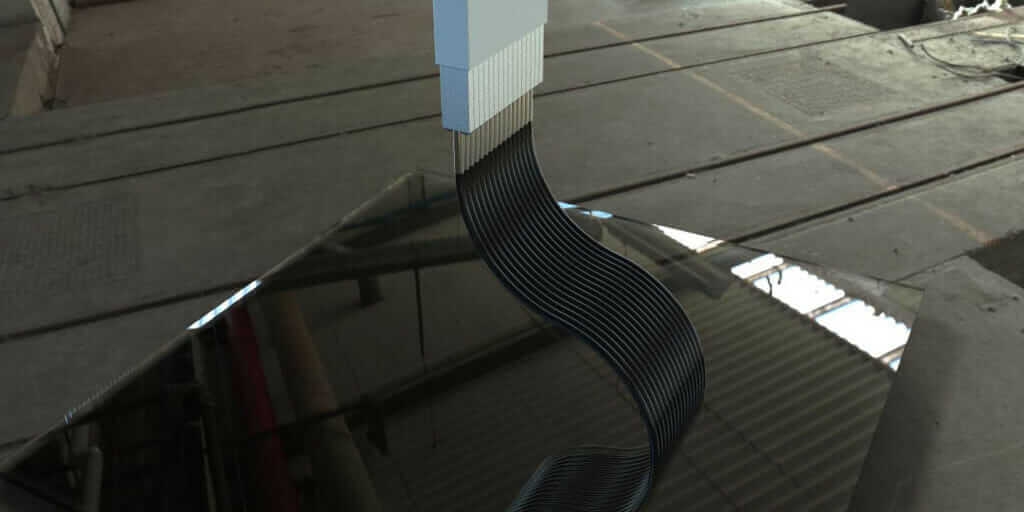

The UV light has the power to cure the epoxies instantly, forming a hard molecular bond between the material and the underlying matrix much faster than most 3D extrusion processes. It gives Continuous Composites the capability to print unique geometries, like curves, in free space.

All of this forms the basis of the company’s claim that its process is 10 times faster than that of its nearest competitor. “Right now, we’re maxing out at 90 inches a minute,” Tyler says. “But we should easily be able to print at up to 1,200 inches a minute.” Of course, that doesn’t make a lot of tangible difference in plastic desk toys. But scale it up to a container ship; a multistory office building full of plumbing and A/C ducts; or a pipeline with integrated sensors, communications, and conductive materials for applications like the Hyperloop, and you can see the appeal.

The process also saves time in producing a complete part that doesn’t require after-manufacture assembly with other components. It’s all done in one pass of the 3D-printer nozzles.

Apart from some of the more way-out 3D-printing capabilities you’ve heard about, like supplying on-demand human tissues and organs, most of the industry is still using thermoplastic. But Continuous Composites’ process lets you print almost anything into fibrous strips or tubular structures. Most 3D printers have a single extrusion nozzle, but Tyler’s experiments with 8- and 16-channel nozzles still produce a nicely even path.

As if all that speed and superior performance isn’t enough, Continuous Composites is also looking at unshackling 3D printing from the single-nozzle gantry and rail system. Instead of the print head slowly laying down the layers of a polymer racing car or Stormtrooper helmet, imagine a system in which the print head (or many of them) follows the path its printing—using the same technology as robot cameras that crawl through pipes—perfect for curves or tubular structures.

“That’ll be the thing that excites people: when they see 16 print heads create a building in one day,” Tyler says. “It’s something we’ll be able to do in the next few years if things keep going well.”

Embracing generative design

It’s also fertile ground for the principles of generative design. One of Tyler’s major problems with 3D printing is how it results in weak spots because of the way the material is laid down on the preceding layer; the calculation algorithms of generative design are great at combating those weaknesses, he says.

“It’s perfect because we’ll be able to orient the fibers against forces properly to meet the constraints of the design,” Tyler says. “Being able to have this discrete control of the fiber, paired with these very powerful software tools, will allow us to make some really impressive objects.”

So now that it’s about to unleash its killer app on the world, Continuous Composites is looking at the next phase. Whether it’s licensing the technology to more established players, growing internally to sell it in-house, or pursuing a blend of the two, one thing’s certain: Star Trek replicator-style made-to-order products are one step closer.

About the author

Drew Turney

After growing up knowing he wanted to change the world, Drew Turney realized it was easier to write about other people changing it instead. He writes about technology, cinema, science, books, and more.