Heavy-equipment manufacturer brings generative design down to Earth

Generative design in heavy manufacturing transforms product optimization and design and cuts costs to improve competitiveness

March 7, 2020 • 6 min read

Claudius Peters, a 113-year-old manufacturer of bulk-materials processing equipment, is undergoing a transformation to become a digital company for the 21st century. Generative design is a game changer for the firm, offering a radical new way to approach product design and optimization. By adapting this technology—which is usually associated with 3D printing—for traditional fabrication methods, the company is making more cost-effective products for a price-sensitive industrial market. Generative design in heavy manufacturing helps cut material, energy costs, and lead times to make Claudius Peters more competitive in changing times.

An old-school company embraces change

German manufacturer Claudius Peters exemplifies the term “heavy industry”: The company produces big industrial machinery and processing plants for the cement, steel, gypsum, and aluminum industries. “We’re the specialists in handling bulk materials,” says Thomas Nagel, operations director at Claudius Peters (CP). In addition to its headquarters near Hamburg, Germany, the company has 12 regional offices in the Americas, Europe, and Asia.

Founded in 1906, CP has manufactured huge, capital-intensive industrial products—conveyors, silos, grinding mills—for more than 100 years. But instead of clinging to its venerable history, Nagel, acting as chief digital officer, is helping the company establish a reputation as a global leader in digital innovation. Claudius Peters initiated an innovation journey in 2014 with the goal of improving business outcomes related to cost, quality, speed of delivery, and customer satisfaction. But the company realized that staying competitive in the 21st century requires more than just new software. In 2018, CP began a further transformation into an agile company, which would require new digital skills and a culture focused on design thinking, experimentation, and iteration.

The innovation journey begins

Working with technology partners such as Autodesk has been key to Claudius Peters’ innovation journey. CP has adopted new tools, including BIM 360, to connect processes across sales, engineering, design, manufacturing, and assembly. The company also found new ways to streamline manufacturing processes using Inventor and finite element method (FEM) analysis. To install its machines, CP began using 3D reality-capture scans with ReCap and Navisworks to capture data at customer facilities, then quickly hand off the files to the engineering and design teams in Germany. “This means we do our job faster, with higher quality, at lower cost, leading to higher customer satisfaction,” Nagel says,

“But our innovation didn’t stop there,” he adds. Inspired by a demonstration of generative design in Fusion 360, Nagel set up a four-hour workshop for the CP team to learn about this emerging technology.

Autodesk generative design software takes design goals and constraints and explores the possible permutations of a design solution, quickly generating dozens of options to choose from. After experimenting with a few generic parts, the team decided to try using generative design to optimize a part from one of CP’s core products for the cement industry—a clinker cooler.

What is a clinker cooler?

The cement industry has been a mainstay for Claudius Peters from its earliest days. Cement manufacturers mix crushed rock and heat it in a kiln to 1,450°C (2,640°F), fusing it into marble-size lumps called “clinker.” The red-hot clinker is discharged to a clinker cooler, a massive machine 50 by 25 meters (164 by 82 feet). Air cools the clinker to around 100°C (212°F) as it’s moved through the cooler. It’s then ground and mixed with other ingredients to form cement.CP began supplying clinker coolers to the industry in the early 1950s, producing more than 700 coolers over the next 60 years. But clinker production consumes a lot of energy, making the cement industry one of the world’s biggest CO2 emitters.

In the early 2000s, CP began developing a next-generation clinker cooler designed to save energy: the ETA Cooler, named after the Greek symbol “η” (“eta”), which denotes energy efficiency. “One of the greatest benefits of our ETA Cooler is outstanding thermal efficiency,” Nagel says. “These energy savings can help reduce the negative environmental impact of cement production.” Today, CP’s main business is replacing existing clinker coolers with ETA Coolers to increase efficiency at cement plants.

Generative design yields surprising results

CP decided to use generative design to optimize a part for the ETA Cooler—a heavy metal piece that had been recently redesigned to remove excess material using traditional design methods. Each cooler has 50 to 60 of these parts, which are bolted together on a series of conveyor lanes that move the molten clinker through the ETA Cooler. “This cast piece has been optimized over and over again,” says Maximilian Lerch, design engineer at CP. “The target was to lower weight and the linked cost of the metal. Even a little weight optimization would have a big effect.

“It was really cool to watch all the engineers gathered around the computer screen, watching generative design create an optimized, strong part out of almost nothing, just the constraints,” Lerch continues. “All the iterations that are needed to come to the best solution are done by the software.”

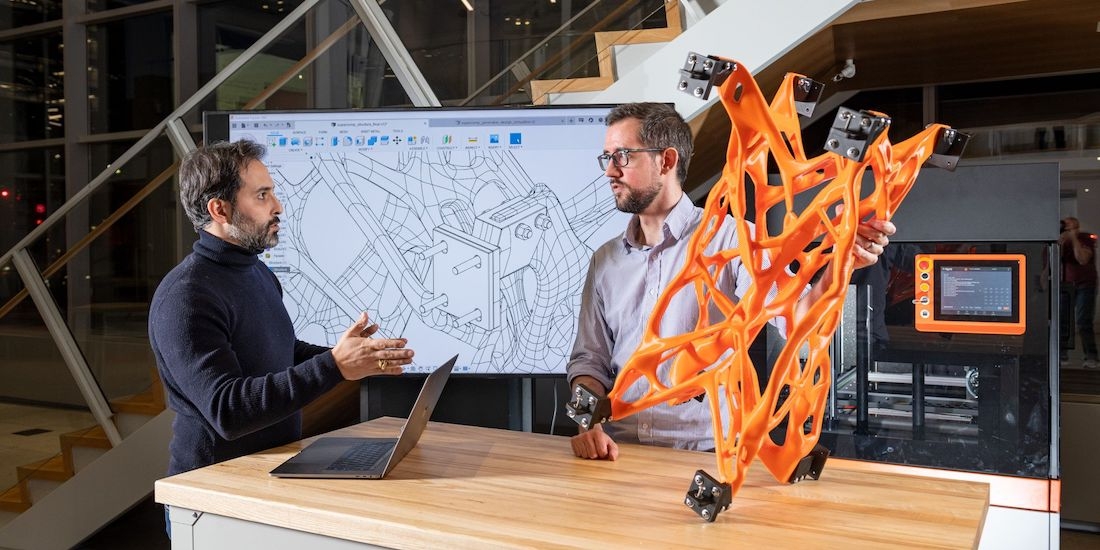

After that first four-hour session with generative design, the team had its first result: “We called it ‘the alien part,’” Nagel says. “The result surprised us—how could it be so different from our optimized part? And 30% to 40% lighter?”

Adapting a generatively designed part for traditional manufacturing

Claudius Peters’ skeptical engineers ran calculations and FEM analysis on the “alien part” and were astonished to find it was more effective than their traditionally optimized version of the part. The team began to analyze the design to figure out how to manufacture it. “Generative design normally uses 3D printing or other additive-manufacturing methods to make the product,” Nagel says. “Our industry will not use 3D-printed parts—it’s too expensive.” But using ideas from generative design and traditional optimization, “it took us only a week to reverse engineer the part so we can make it using traditional manufacturing methods.”

With Inventor and FEM analysis, the team tested different fabrication solutions with Claudius Peters’ foundry. “We decided to move from a cast part to a solution with laser-cut plates and welding,” Nagel says. “We’ve made the part an additional 25% lighter, faster to make, and more cost efficient.” The team continues to study design options for the transport part, finding additional opportunities for improvement and even more cost savings. “It should be rolled out into production very soon,” Nagel continues. “I expect the part will be in operation somewhere in the world within the year.”

Reaping the benefits of generative design

CP’s generatively designed part can ultimately save the company a significant amount of money on each clinker cooler it installs. With the weight of the transport part reduced by about 20 kilograms (44 pounds), the company anticipates saving about €100 (USD $113) per part—multiplied by 60 or more parts in each cooler. In addition, less weight means lower shipping cost. “From the first prototype we developed, we believed that generative design will help us achieve better costs for our products and make us more competitive,” Nagel says.

Generative design also delivers greater sustainability. “We can move from a heavier part cast in a foundry in India or Turkey to a lighter part—a welded design that we can even do in our workshop here,” Nagel says. “We save material, energy, transportation time, and other negative effects on the environment.”

Claudius Peters is now at the point where generative design is becoming a standard process for optimizing existing parts or designing new ones. “We will figure out more parts on which to apply optimizations and material reductions in the future,” Nagel says. “Part by part, we’ll try to see if generative design will have the same positive benefits.”